Overall offshore wind generating set conveying and mounting all-in-one ship with primary floating body and secondary floating body and overall conveying and mounting method

A technology for wind turbines and overall transportation, which is applied in wind power generation, transportation and packaging, and motor vehicles, and can solve problems such as punctures, multiple influencing conditions, and high installation costs of wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

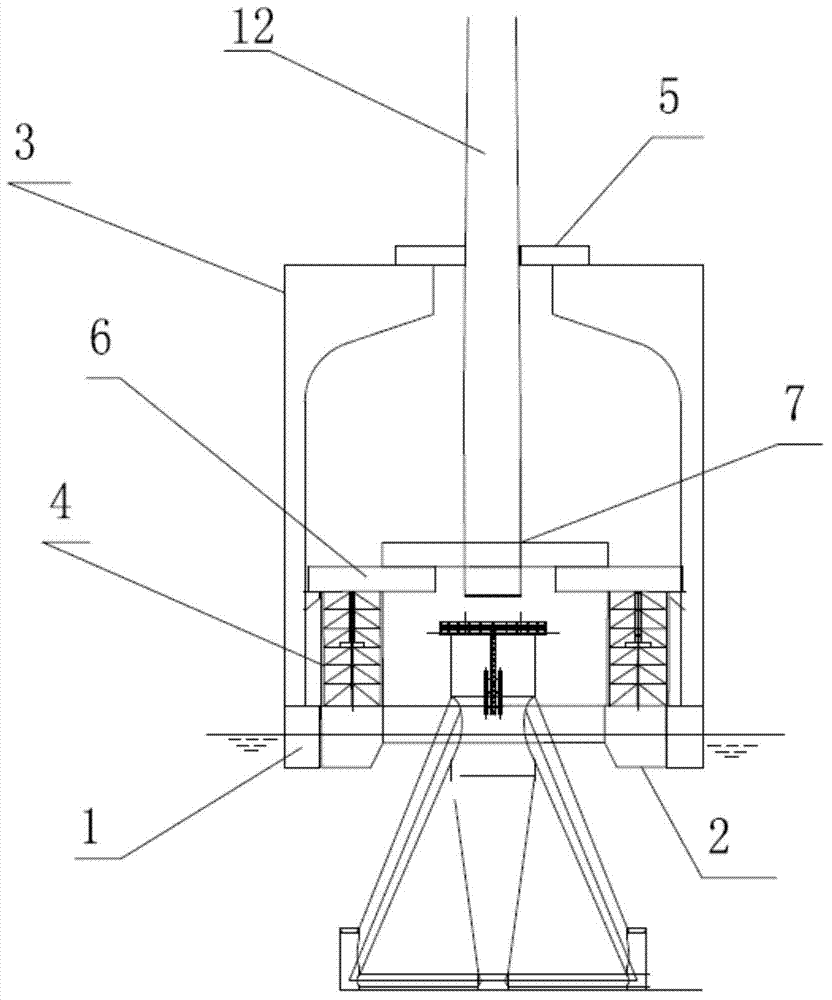

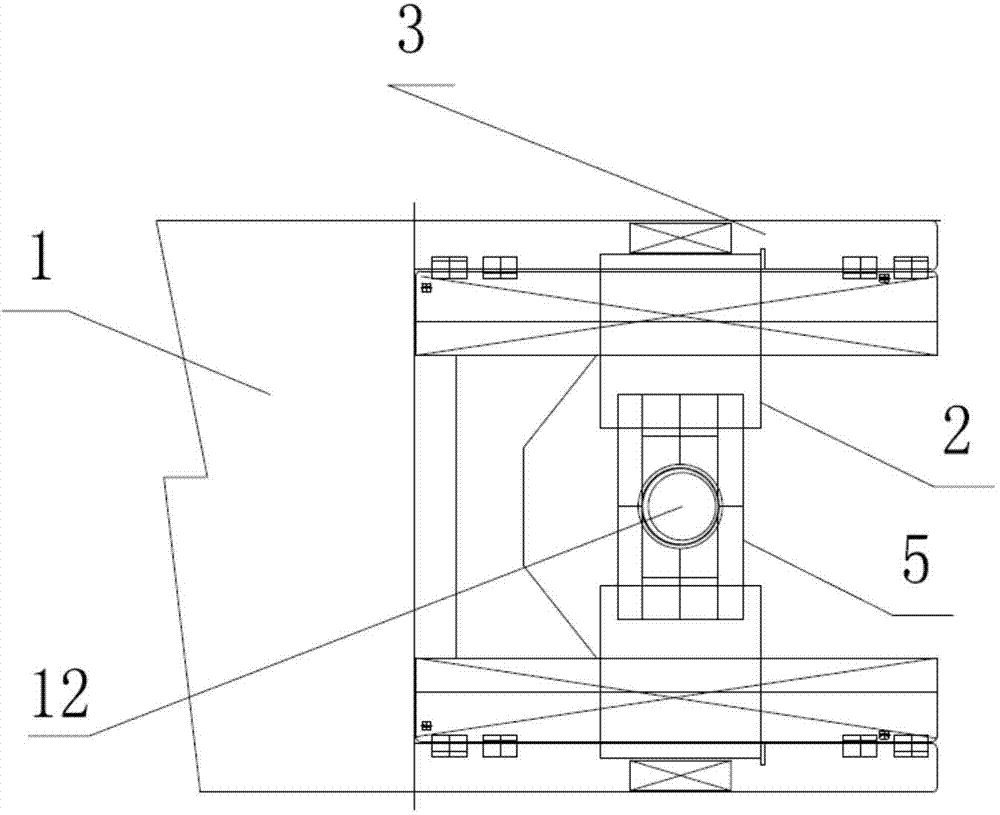

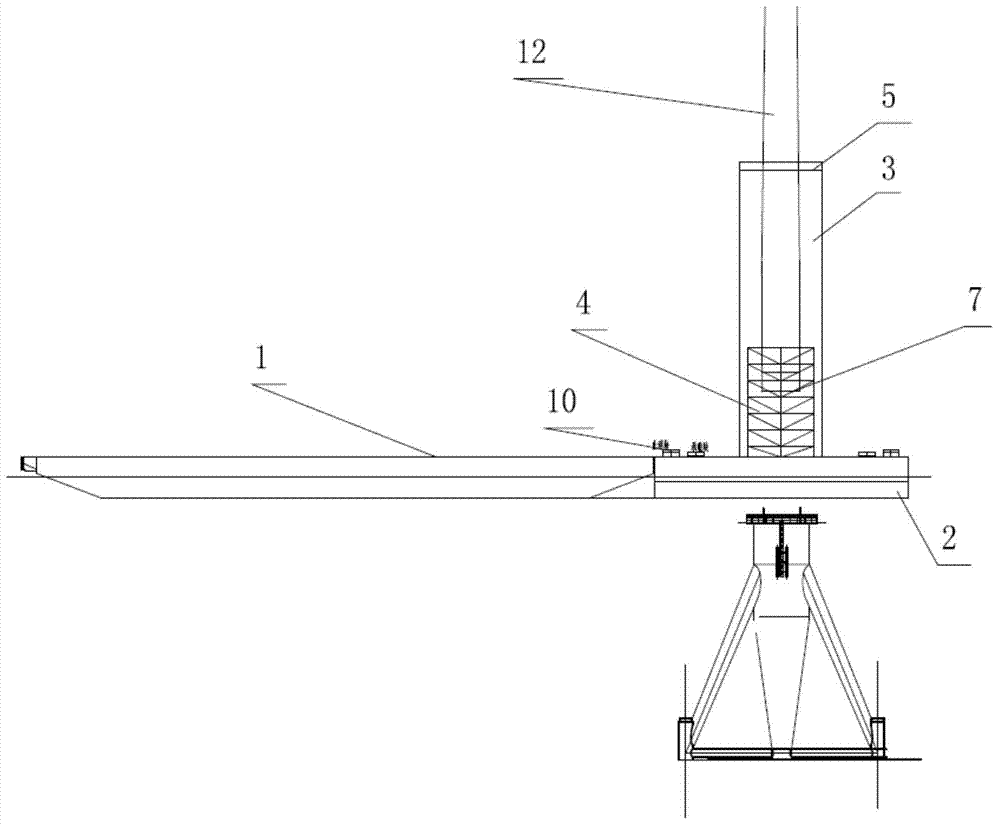

[0015] Such as Figure 1 to Figure 3 As shown, the overall transportation and installation of the mother and child double floating body offshore wind turbine generator set of the present invention includes a mother ship floating body 1 and a daughter ship floating body 2. The fixed frame 3 is provided with an upper solid locking device 5, the upper solid locking device 5 passes through the tower tube 12, the upper part of the lifting device 4 is connected to the load-bearing platform 6, and the rotating fine-adjustment locking device 7 is installed on the load-bearing platform 6, and the rotating fine-adjustment is locked The installation 7 includes a locking jack 8 and a rotating jack 9, the lifting device 4 is a lifting jack, the sub-ship floating body 2 and the mother ship floating body 1 are combined and separated by the locking device 10, and the sub-floating bodies on the left and right sides are fixedly connected by connecting beams.

[0016] The construction method inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com