Semi-submersible module and its assembly method for combining large-scale floating body on water

A semi-submersible, combined technology, applied to floating buildings and other directions, to achieve the effect of easy construction, good structural strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

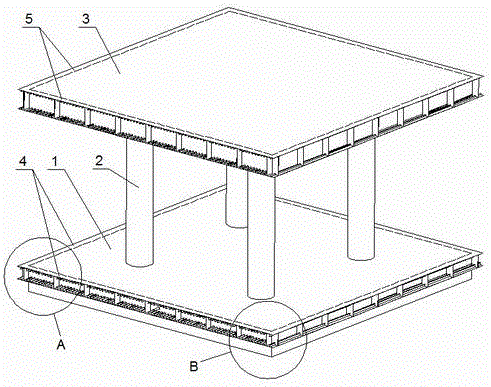

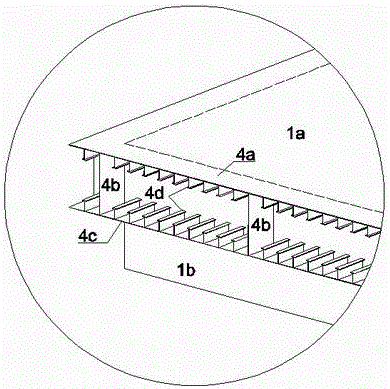

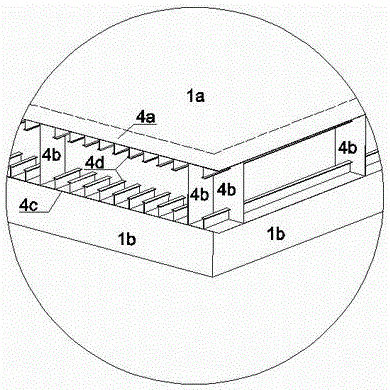

[0017] figure 1 , 2 , 3 shows a structural diagram of a semi-submersible module used to form a large floating body on water. In the figure, the semi-submersible module used to form a large floating body on water includes a buoyant tank 1, a column 2, an upper platform 3, a buoyant tank connecting bridge 4 and an upper platform connecting bridge 5, and a buoyant tank is arranged around the buoyant tank 1 Connecting bridge 4, upper platform connecting bridge 5 is arranged on the periphery of upper platform 3, buoyant tank 1 is fixedly connected with upper platform 3 by column 2 to form a semi-submersible module. The interior of the buoyancy tank 1 is provided with a plurality of standard liquid tanks, and the standard liquid tanks are collected to the ballast centralized control room of the upper platform 3 through the remote control pipelines and remote control valves of the column 2 . The upper platform 3 is a large-scale combined floating body that provides a working place,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com