Micro-expansion moderate heat portland cement and preparation method thereof

A Portland cement and micro-expansion technology, applied in the field of micro-expansion medium thermal Portland cement and its preparation, can solve the problems of fluctuation of raw material composition, out of control shape, low expansion rate, etc. Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

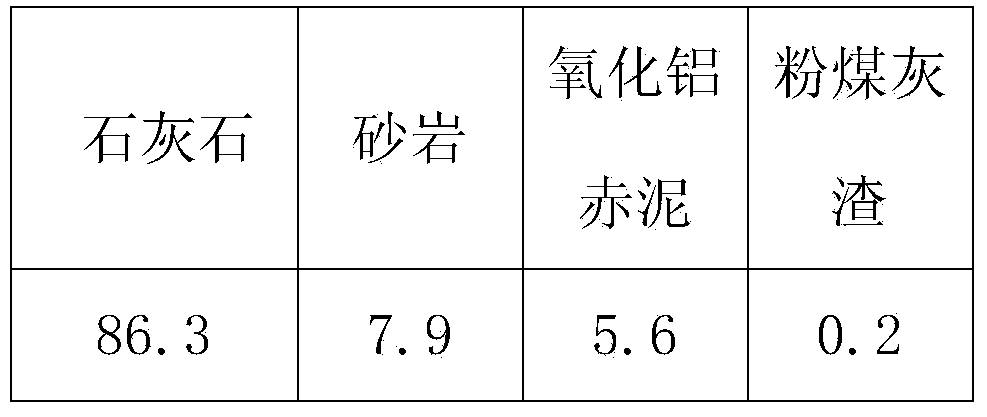

[0039] A kind of micro-expansion medium heat portland cement, its weight ratio composition is clinker 79.5, limestone 6, mineral powder 9 desulfurization gypsum 6.5; wherein, the raw material weight ratio composition of clinker is limestone 86.3, sandstone 7.9, alumina red mud 5.6, fly ash slag 0.2. The chemical composition of the raw limestone used is 46% calcium oxide and 3.9% magnesium oxide.

Embodiment 2

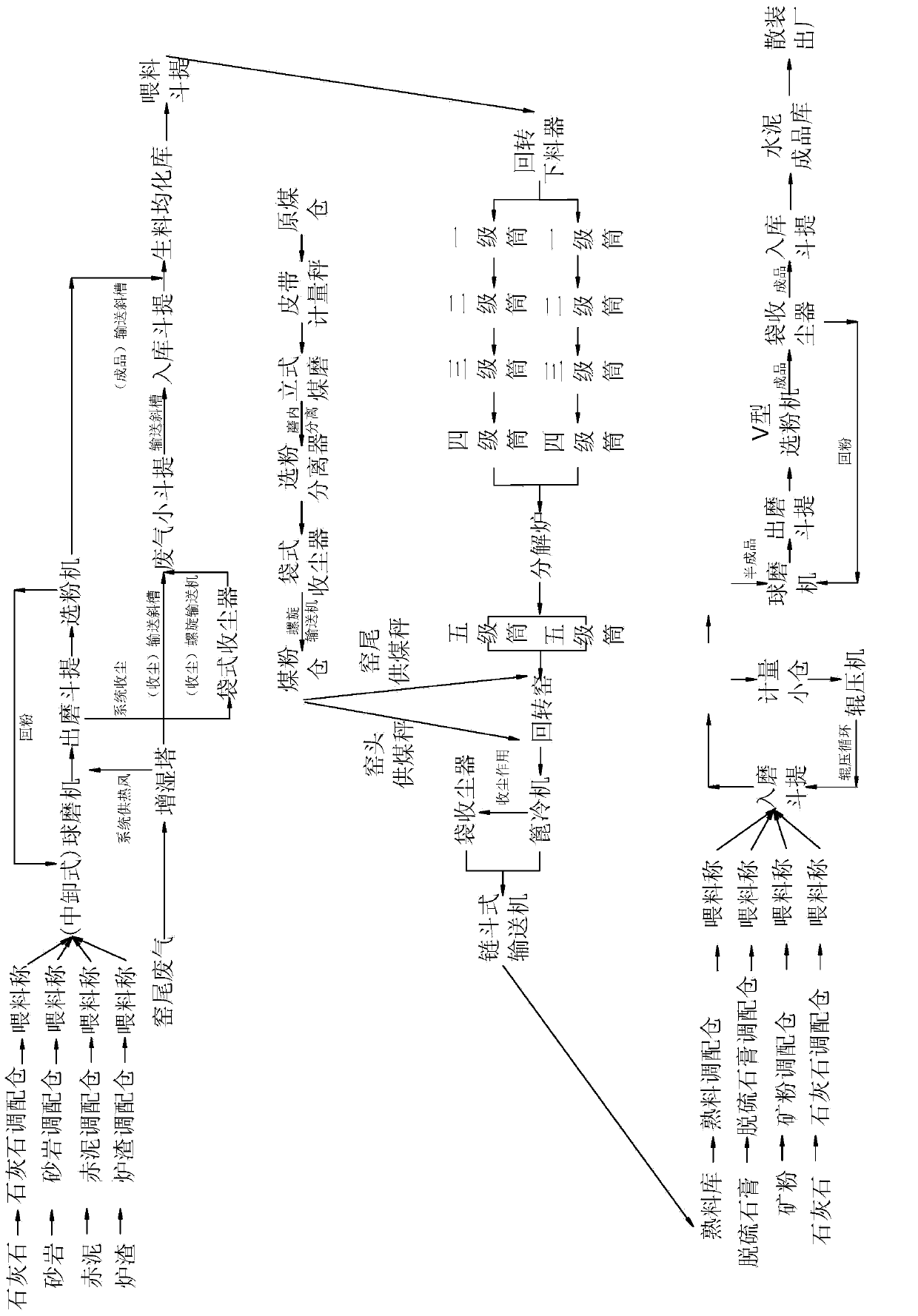

[0041] A method for preparing micro-expansion medium-heat Portland cement, the preparation process comprising the following process steps:

[0042] (1) clinker process

[0043] The weight ratio composition of raw materials is limestone 86.3, sandstone 7.9, alumina red mud 5.6 and fly ash slag 0.2. The temperature in the calciner is controlled at 880°C; The clinker is obtained by calcining; the clinker is cooled by the grate cooler, and the driving speed of the grate cooler is 5.5-6.5r / min, and then the cement process is carried out;

[0044] (2) Cement process

[0045] The clinker prepared in step (1) is mixed with limestone, mineral powder and desulfurized gypsum in a weight ratio of clinker 79.5, limestone 6, mineral powder 8 and desulfurized gypsum 6.5; the micro-expanded gypsum of the present invention is obtained through cement grinding Moderate heat Portland cement.

[0046] The chemical composition of limestone raw materials used in production includes calcium oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com