Drilling pressure-bearing plugging agent for oil-gas wells and preparation and application thereof

A plugging agent, oil and gas well technology, applied in the field of oil drilling, to achieve the effect of safe construction, high strength and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

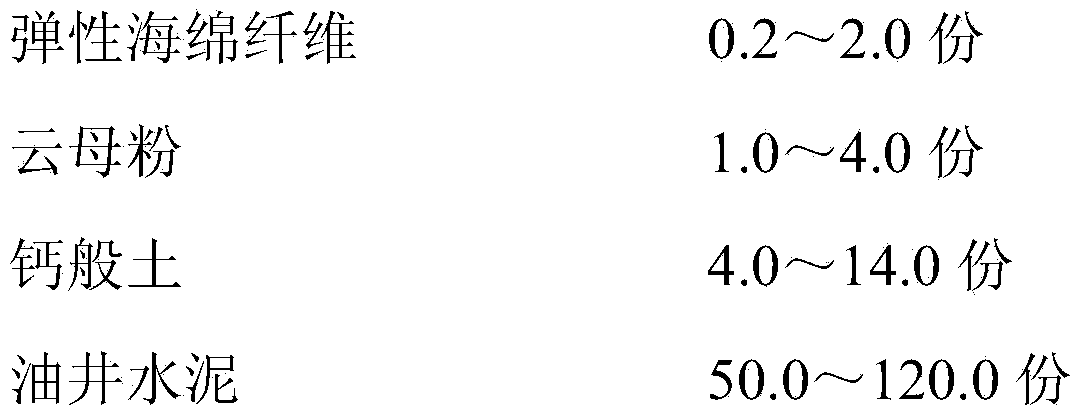

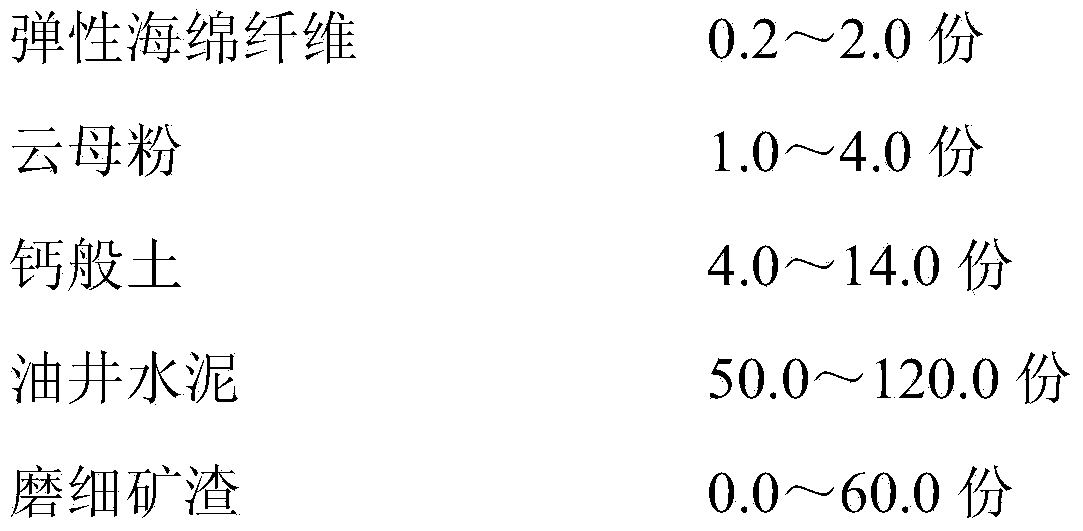

[0020] The leak-stopping agent consists of the following components in parts by weight:

[0021] 50 parts of oil well cement, 0.8 parts of elastic sponge fiber, 3.0 parts of mica powder, 10.0 parts of calcareous soil, 50 parts of finely ground slag, and clear water with a solid-to-liquid weight ratio of 1.80, wherein the solids include mica powder, calcareous soil, and oil well cement And ground slag, the liquid is clear water.

[0022] The preparation method and use method of the pressure-bearing plugging agent for oil and gas well drilling, the steps are as follows:

[0023] Preparation: the materials are added into clean water according to the specified ratio, mixed and stirred, and prepared into a pressure-bearing plugging agent for oil and gas well drilling.

[0024] Use: run down the bare drill pipe to the top 700-400m of the lost zone, open the well, replace the pressure-bearing lost circulation agent to the bottom of the light drill pipe, then close the well, squeeze ...

Embodiment 2

[0026] The leak-stopping agent consists of the following components in parts by weight:

[0027] 100 parts of oil well cement, 0.8 parts of elastic sponge fiber, 3.0 parts of mica powder, 10.0 parts of calcareous soil, 0 parts of finely ground slag, and clear water with a solid-to-liquid weight ratio of 1.80, wherein the solids include mica powder, calcareous soil, and oil well cement And ground slag, the liquid is clear water.

[0028] For the preparation method and application method of the pressure-bearing plugging agent for oil and gas well drilling, refer to Example 1.

Embodiment 3

[0030] The leak-stopping agent consists of the following components in parts by weight:

[0031] 100 parts of oil well cement, 0.8 parts of elastic sponge fiber, 3.0 parts of mica powder, 10.0 parts of calcareous soil, 0 part of finely ground slag, and clear water with a solid-to-liquid weight ratio of 1.60, wherein the solids include mica powder, calcareous soil, and oil well cement And ground slag, the liquid is clear water.

[0032] For the preparation method and application method of the pressure-bearing plugging agent for oil and gas well drilling, refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com