A leaf spring hydraulic quenching forming device

A hydraulic and leaf spring technology, applied in the field of leaf spring hydraulic quenching and forming devices, can solve the problems of increased operator workload, high cost of replacing medium, and high operating cost, and achieves a reduction in labor intensity, high production efficiency, and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

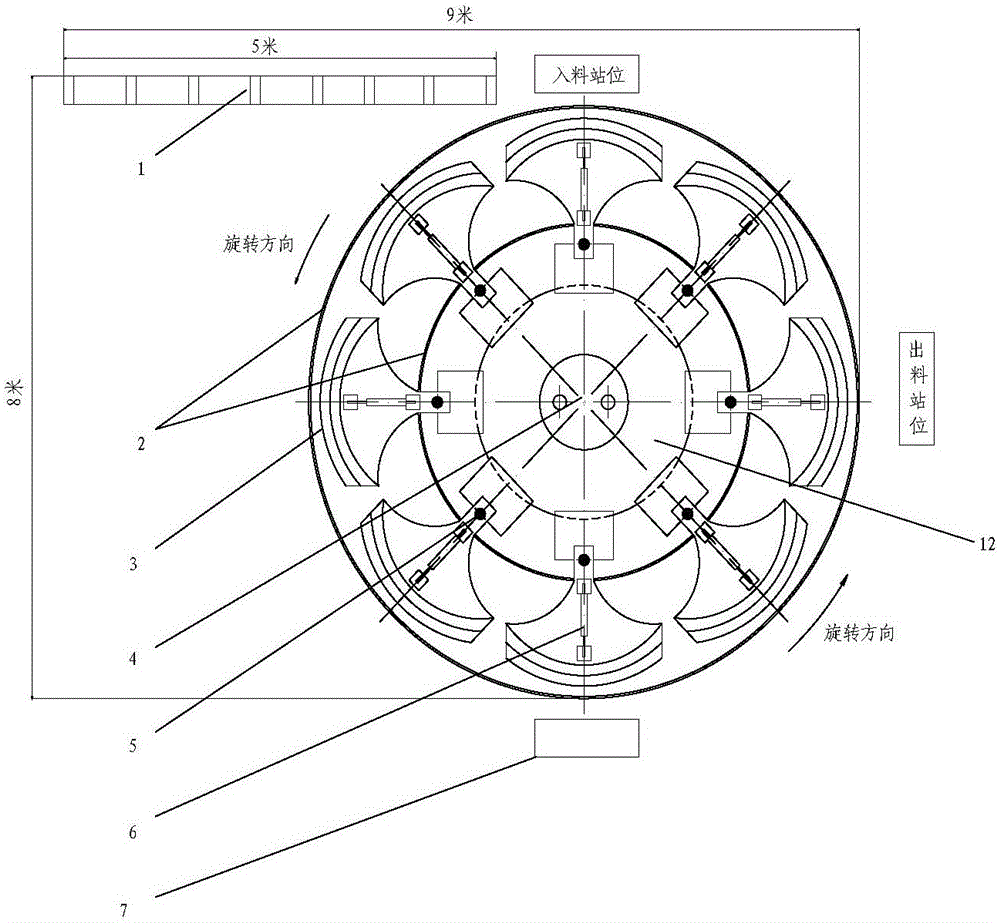

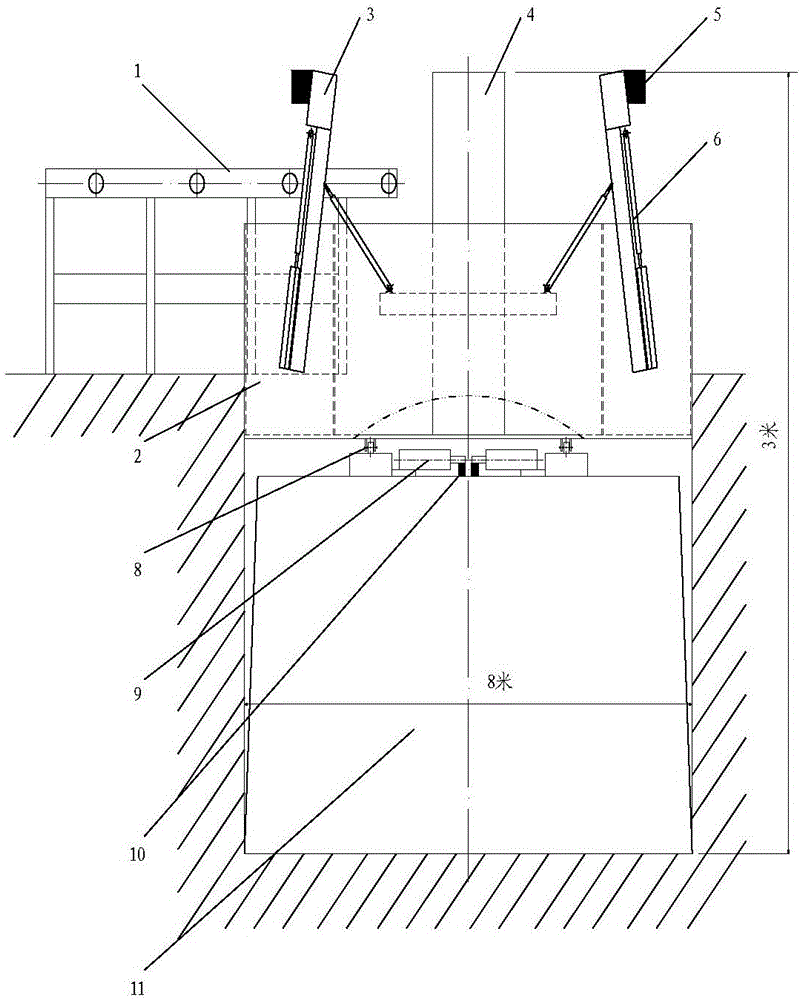

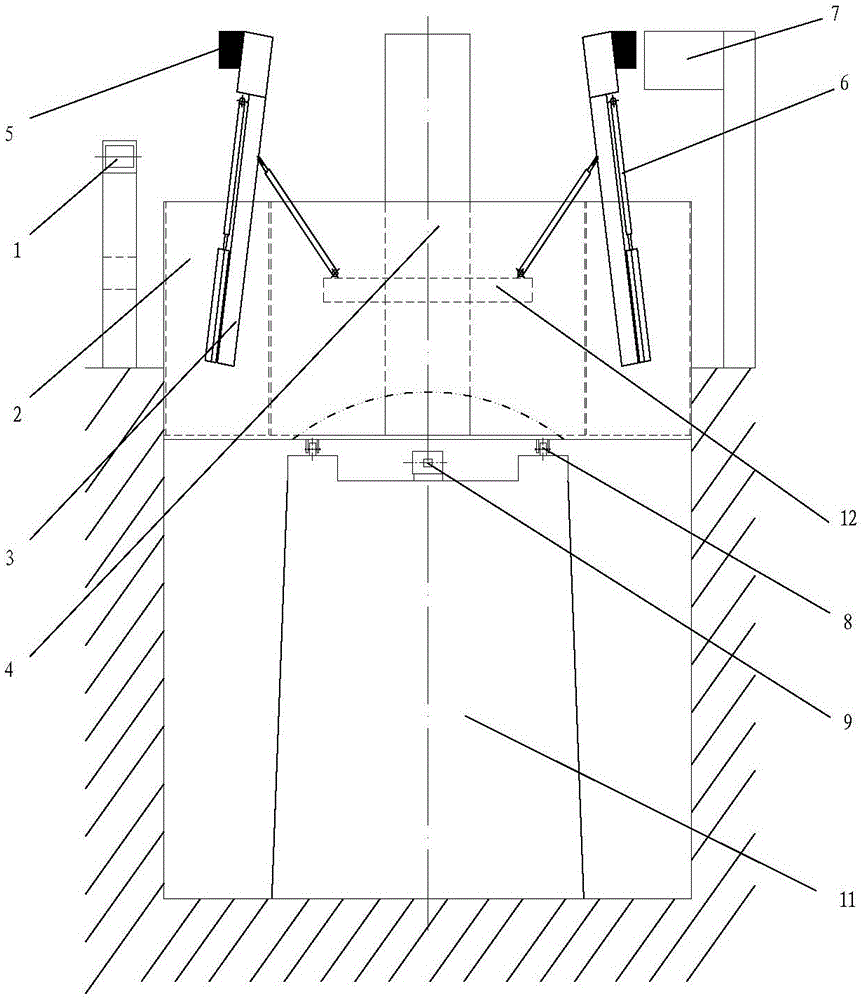

[0022] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] as attached Figure 1-3 As shown, the present invention includes a support column 11, a disc, an annular oil tank 2, a central valve 4, 8 sets of forming fixtures 3, a fixture cylinder 6, a support roller 8, a driving and braking hydraulic cylinder 9, a plunger pump motor unit, and PLC control system, the forming fixture 3 is provided with a fixture cylinder 6, and the control system includes an induction plate 7 and a proximity switch 5;

[0024] The disc is located in the middle of the annular oil tank 2, the support roller 8 is connected to the disc, the disc and the support roller are installed above the support column 11, the disc is connected to the support roller, and the support column is provided with an annular track corresponding to the support roller; the center The valve 4 and the forming fixture 3 are fixed on the disk, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com