Process for optimizing cold rolling reduction in machining process of Zn-containing and Er-containing high-Mg aluminum alloy plate resistant to long-term corrosion

A technology of aluminum alloy plate and cold rolling deformation, which is applied in the field of non-ferrous metals, can solve the problems of reducing the service life of materials, stress corrosion, and aluminum alloys cannot be strengthened by heat treatment, etc., and achieve the effect of improving service life and high long-term corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1) Same as Comparative Example 1.

[0034] 2) Cold rolling the Zn, Er and high Mg aluminum alloy obtained in step 1), the cold deformation is 55%±2% (due to the unevenness of rolling, there is a 2% error in the deformation).

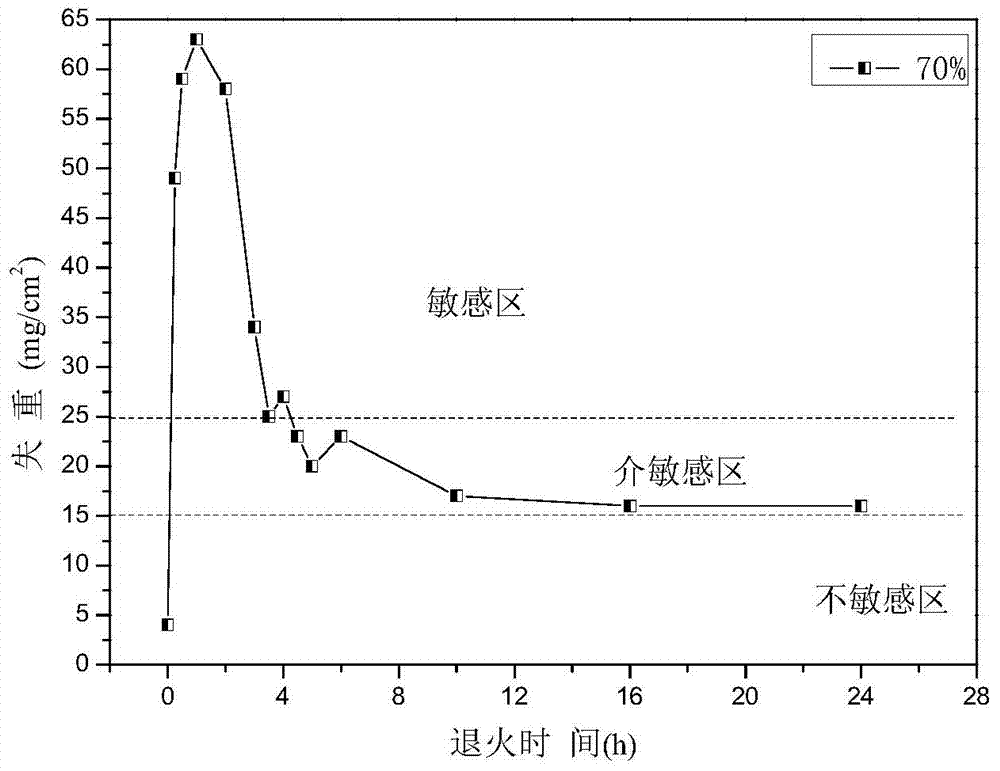

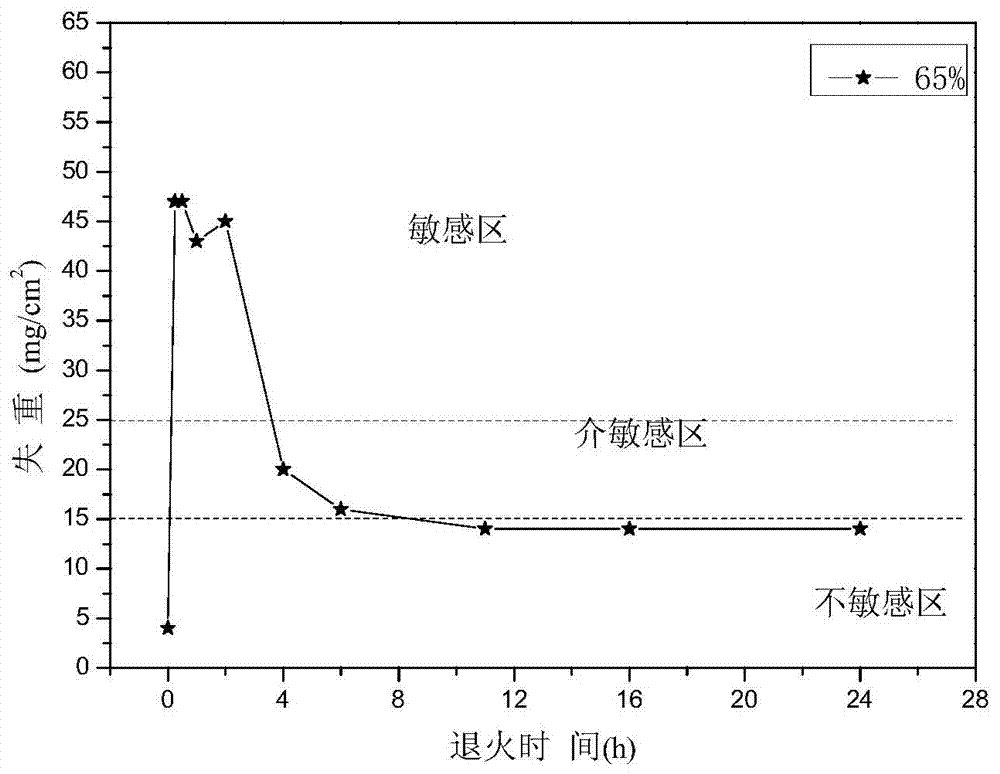

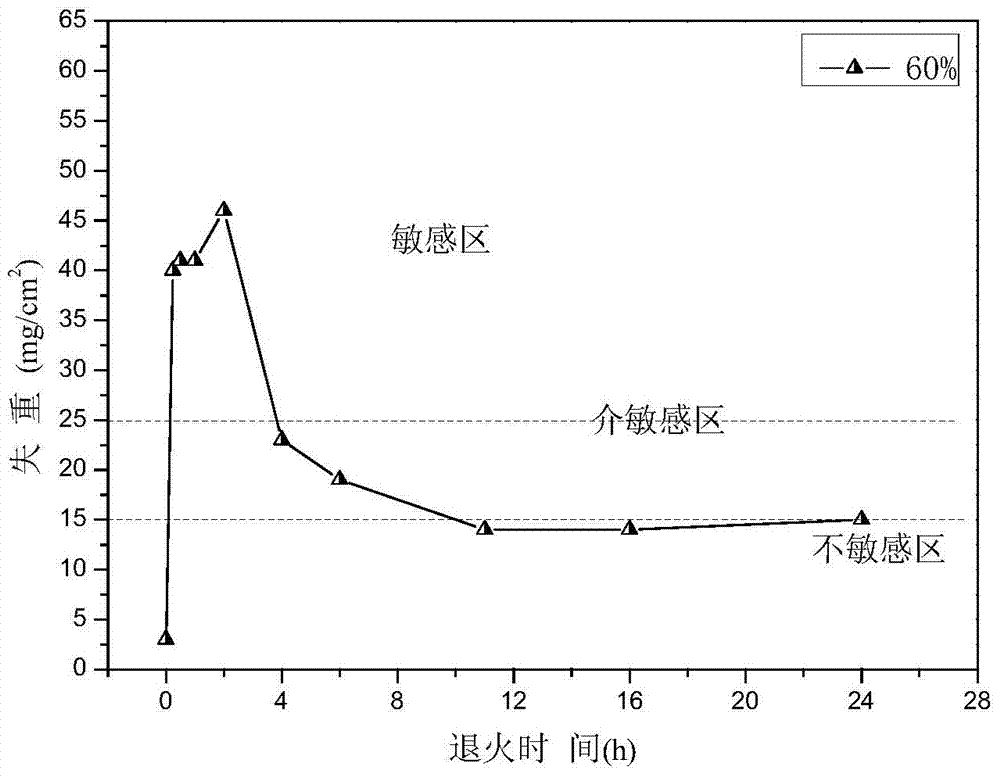

[0035] 3) The cold-rolled sheet obtained in step 2) is annealed at 240° C. for different times. According to the American Society for Testing and Materials standard AST G67, the nitric acid weight loss test was carried out on the alloy cold-rolled and different annealed samples, and the intergranular corrosion susceptibility of the material was evaluated by the weight loss per unit area of the alloy before and after immersion. The change curve of weight loss per unit area with annealing time is as follows: Figure 5 shown.

[0036] Depend on Figure 1-Figure 5 It can be seen that after annealing at 240 °C for each deformation alloy, the weight loss per unit area first increases and then decreases with the prolongation of the annealing ti...

Embodiment 2

[0038] 1) The cold-rolled sheets obtained in step 2) of Comparative Example 1, Comparative Example 2, Comparative Example 3, Comparative Example 4 and Example 1 were annealed at 240° C. for 2 hours and then air-cooled. The exfoliation corrosion test was carried out on the annealed sample according to ASTM G66-99 standard of the American Society for Testing and Materials, and the exfoliation corrosion resistance grade of the material was evaluated by the corrosion morphology of the alloy after immersion. The exfoliation corrosion morphology of the annealed state at 240℃ / 2h for each deformation is as follows Image 6 shown.

[0039] Depend on Image 6It can be seen that the alloys with different deformation amounts in this state are corroded to different degrees, and a large number of corrosion pits are formed on the surface of the alloy with a deformation amount of 70%±2%, and the corrosion pits have slightly penetrated into the surface of the sample (at the arrow), and the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com