A connection structure and connection construction method of monitoring pipe and vacuum membrane in soft foundation treatment

A technology for soft foundation treatment and connection structure, which is applied in basic structure engineering, soil protection, construction, etc. It can solve the problems of cracking and air leakage at the connection, maintenance of the joint that cannot be maintained, maintenance and remediation that cannot be repaired, etc., and achieves good sealing. , stable performance, simple material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

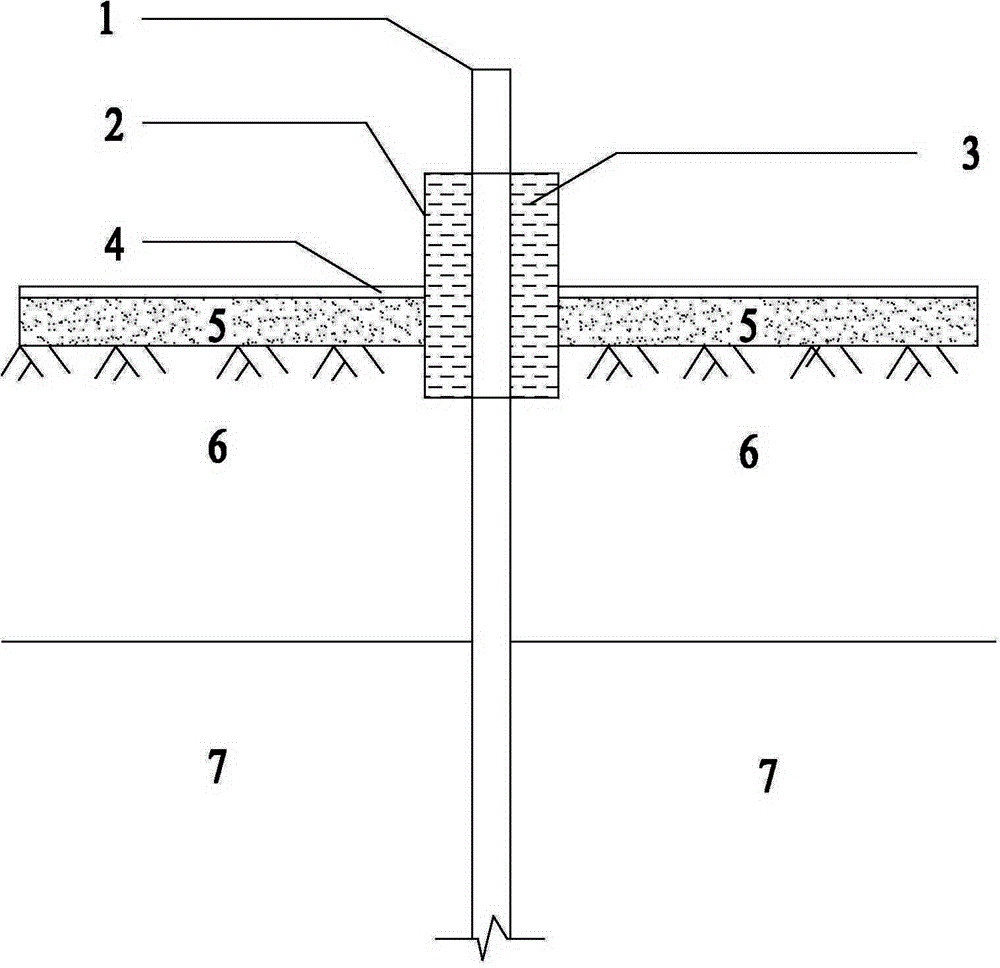

[0028] A method for connecting a monitoring tube and a vacuum membrane in soft ground treatment, comprising the following steps:

[0029] a. Drill the hole vertically until the base layer, bury the lower end of the monitoring pipe 1 in the base layer 2m, and the upper end of the monitoring pipe 1 is 1m higher than the sand cushion layer 5;

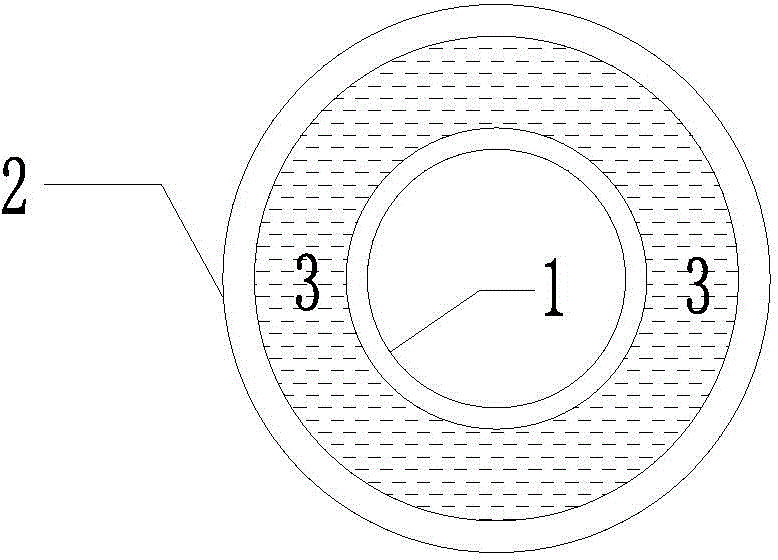

[0030] b. Coaxially embed casing 2 outside the monitoring pipe 1, the diameter of the casing 2 is 5cm larger than the monitoring pipe 1, the lower end of the casing 2 reaches 1m in the foundation treatment layer 6, and the upper end of the casing 2 flush with the upper end of the monitoring tube 1;

[0031] c. the vacuum film 4 is tiled on the sand cushion 5 and the opening of the vacuum film 4 passes through the casing 2, and the vacuum film 4 is bonded with waterproof glue around the casing 2;

[0032] d. Pour the clay slurry 3 into the gap between the casing and the monitoring pipe, the lower liquid level of the clay slurry is in the f...

Embodiment 2

[0036] A method for connecting a monitoring tube and a vacuum membrane in soft ground treatment, comprising the following steps:

[0037] a. Drill the hole vertically until the base layer, bury the lower end of the monitoring pipe 1 in the base layer 1.2m, and the upper end of the monitoring pipe 1 is 1m higher than the sand cushion layer 5;

[0038] b. Coaxially embed casing 2 outside the monitoring pipe 1, the diameter of the casing 2 is 4cm larger than the monitoring pipe 1, the lower end of the casing 2 reaches 4m in the foundation treatment layer 6, and the upper end of the casing 2 0.5m lower than the upper end of the monitoring tube 1;

[0039] c. the vacuum film 4 is tiled on the sand cushion 5 and the opening of the vacuum film 4 passes through the casing 2, and the vacuum film 4 is bonded with waterproof glue around the casing 2;

[0040] d. Pour the clay slurry 3 into the gap between the casing and the monitoring pipe, the lower liquid level of the clay slurry is i...

Embodiment 3

[0044] A method for connecting a monitoring tube and a vacuum membrane in soft ground treatment, comprising the following steps:

[0045] a. Drill the hole vertically until the base layer, bury the lower end of the monitoring pipe 1 in the base layer 1m, and the upper end of the monitoring pipe 1 is 1m higher than the sand cushion layer 5;

[0046] b. Coaxially embed casing 2 outside the monitoring pipe 1, the diameter of the casing 2 is 6cm larger than the monitoring pipe 1, the lower end of the casing 2 reaches 2m in the foundation treatment layer 6, and the upper end of the casing 2 flush with the upper end of the monitoring tube 1;

[0047] c. the vacuum film 4 is tiled on the sand cushion 5 and the opening of the vacuum film 4 passes through the casing 2, and the vacuum film 4 is bonded with waterproof glue around the casing 2;

[0048] d. Pour the clay slurry 3 into the gap between the casing and the monitoring pipe, the lower liquid level of the clay slurry is in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com