Parting water-stop design method of concrete cast-in-situ diaphragm wall of deep overburden layer dam foundation

A technology of deep covering layer and design method, which is applied in water conservancy projects, underwater structures, infrastructure projects, etc., can solve the problems of poor anti-seepage effect and leakage of anti-seepage panels, so as to improve the anti-seepage effect and improve the The effect of service life and simple and convenient construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

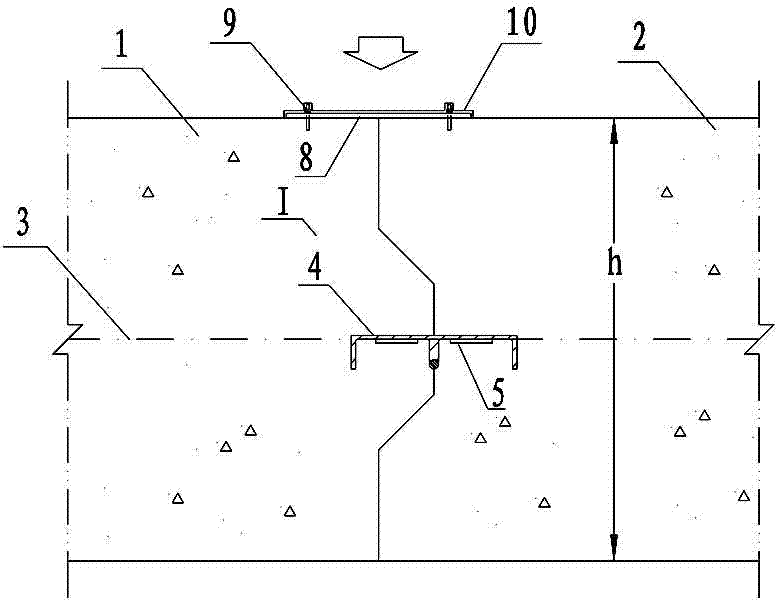

[0013] Such as figure 1 , 2 As shown, in the design method for seam sealing of concrete cast-in-place cut-off walls of deep overburden dam foundations according to the present invention, the first step is to set the vertical joints between adjacent concrete cast-in-place cut-off walls 1 and 2 as broken lines seam, the fold line seam is a "convex"-shaped structure along the thickness h direction of the cut-off wall, and the construction chisels are carried out between the seams;

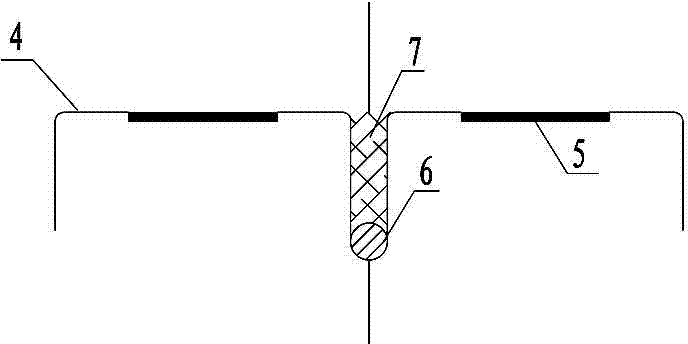

[0014] The second step is to vertically set the water-stop copper sheet 4 (1.2mm thick copper sheet) with a "W" cross-section at the position where the fold line seam is located at the axis 3 of the cut-off wall, and then compound it with GB material with a length of 100mm and a thickness of 6mm The plate 5 is glued to both sides of the water-stop copper sheet 4; at the same time, fill the φ25mm neoprene rod 6 in the convex body cavity in the middle of the water-stop copper sheet 4, and fill it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com