Multipurpose integrated plastic supporting module and splicing structure thereof

A support module, multi-purpose technology, applied in drinking water installations, water supply installations, drainage structures, etc., can solve the problems of poor side bearing performance, collapse, weak connection force, etc., to achieve large support space, less material, production and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

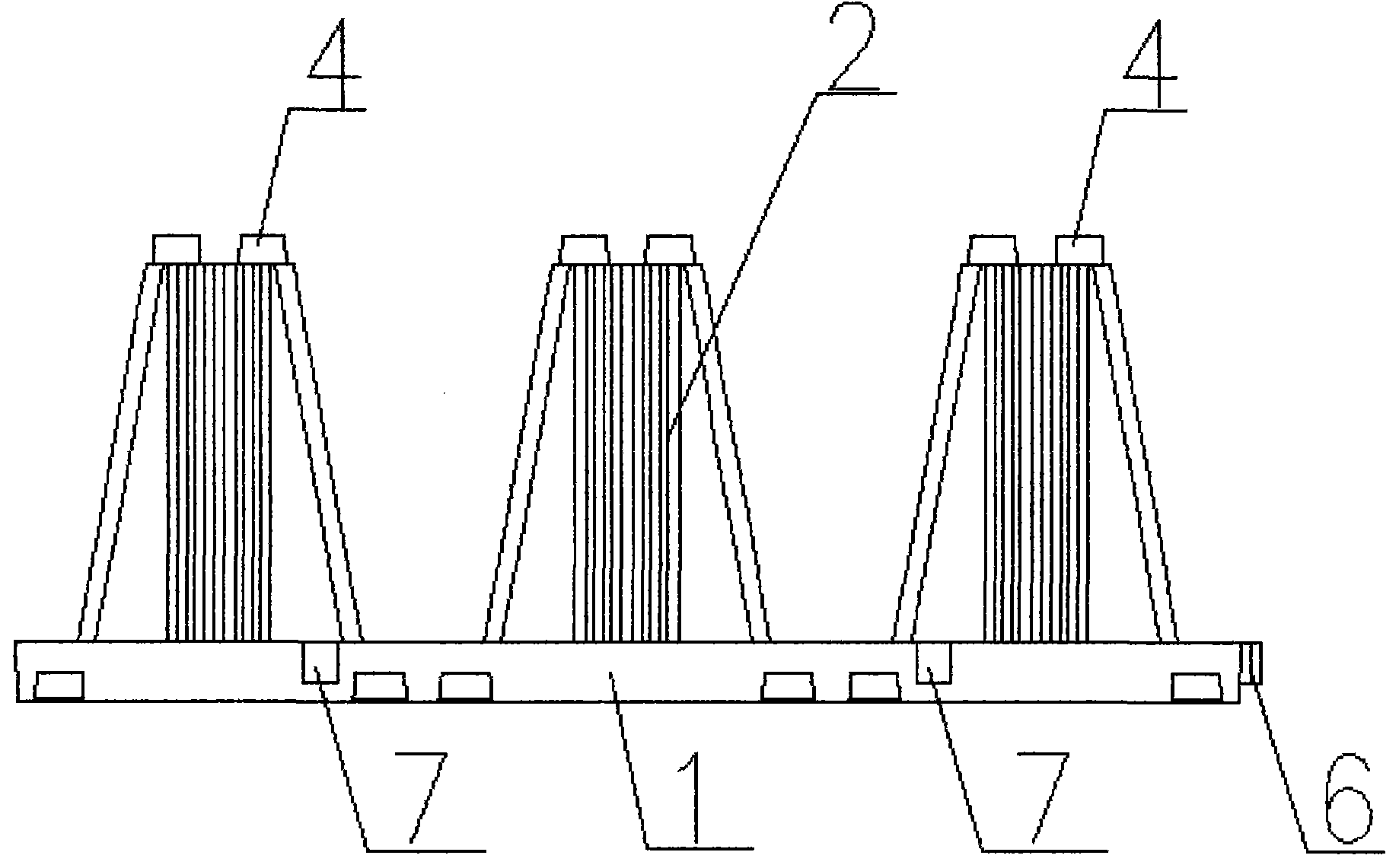

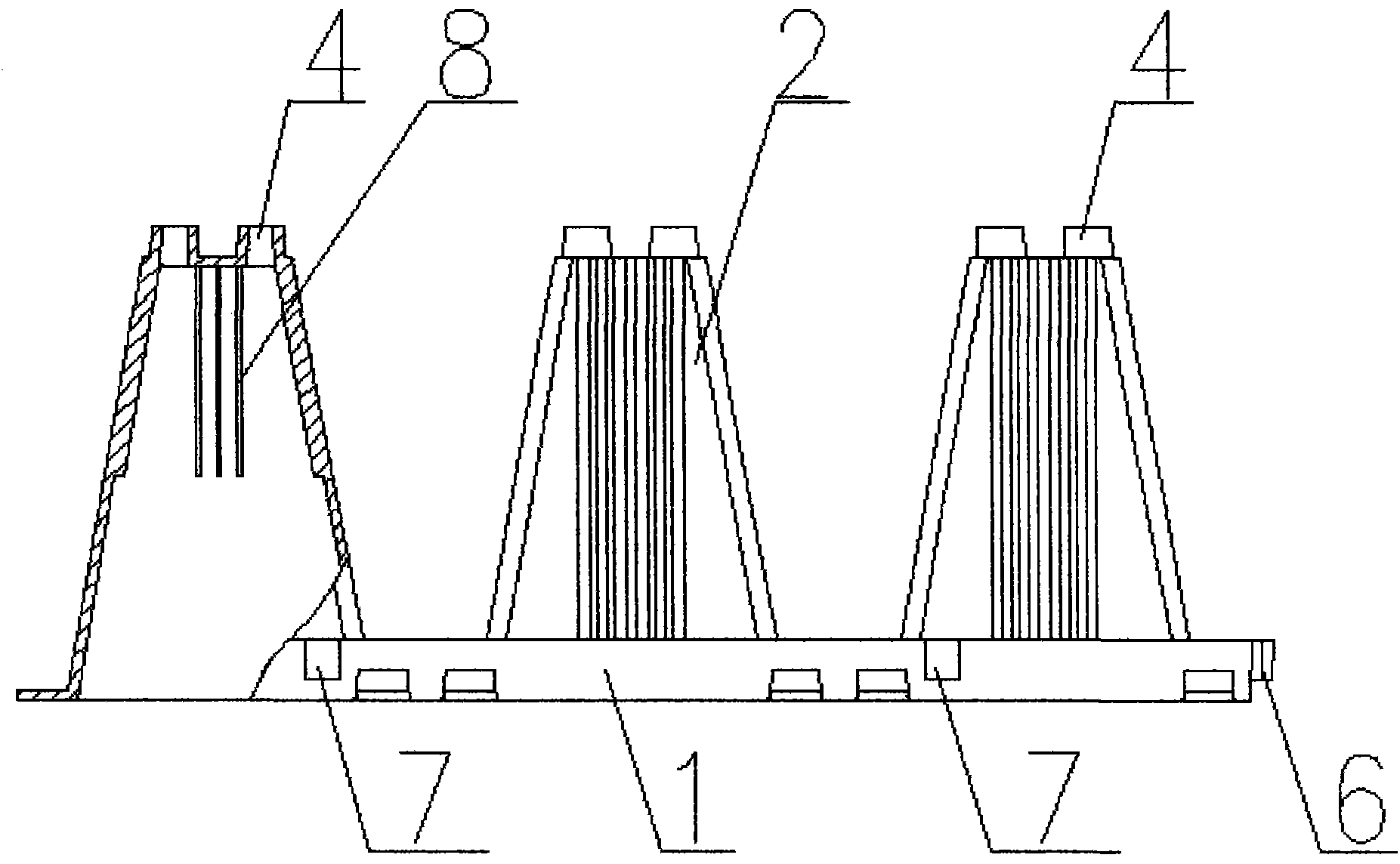

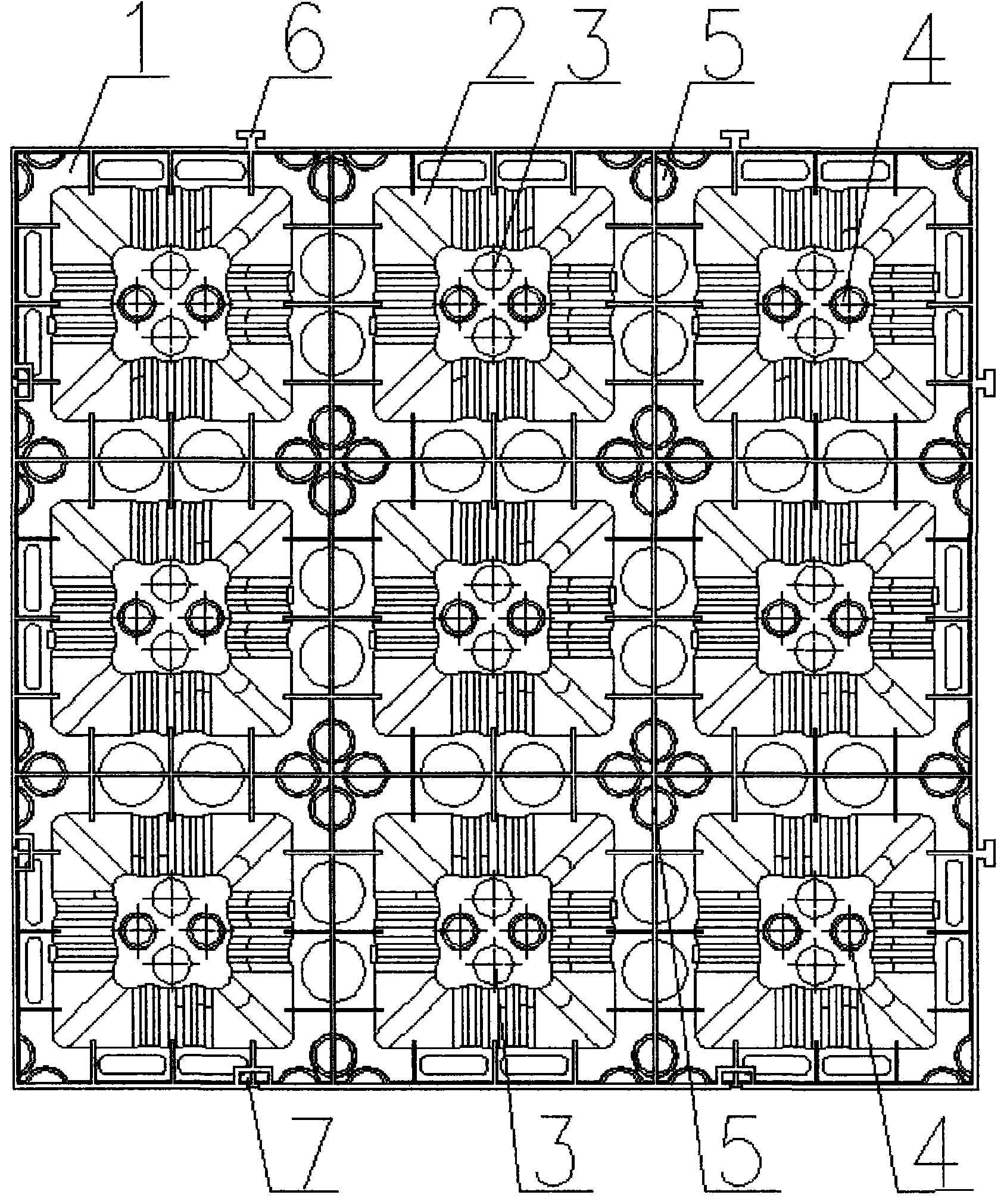

[0026] figure 1 It is a multi-purpose integrated plastic support module, which is composed of a base plate 1 and a support cylinder 2. The support cylinder 2 is a regular square cylinder with a large bottom and a small top and a hollow inner cavity. The bottom of the regular square is open and the edge of the opening is integrally connected with the substrate. The top of the regular square is provided with a convex connection. With cylindrical pin 4 and through connection with cylindrical slotted hole 3.

[0027] In order to increase the pressure bearing capacity of the basic plastic support module, the side wall of the square prism cylinder is set as a wavy reinforced side wall.

[0028] In addition, the following compression test has confirmed that the side wall of the plastic support module has the largest deformation due to compression at a height of 1 / 3 from the top surface, indicating that the damage position of the plastic support module is basically at a height of 1 / 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com