Vacuum type screw engine

An engine and vacuum technology, applied in the field of vacuum screw engines, can solve the problems of energy consumption and environmental pollution, and achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

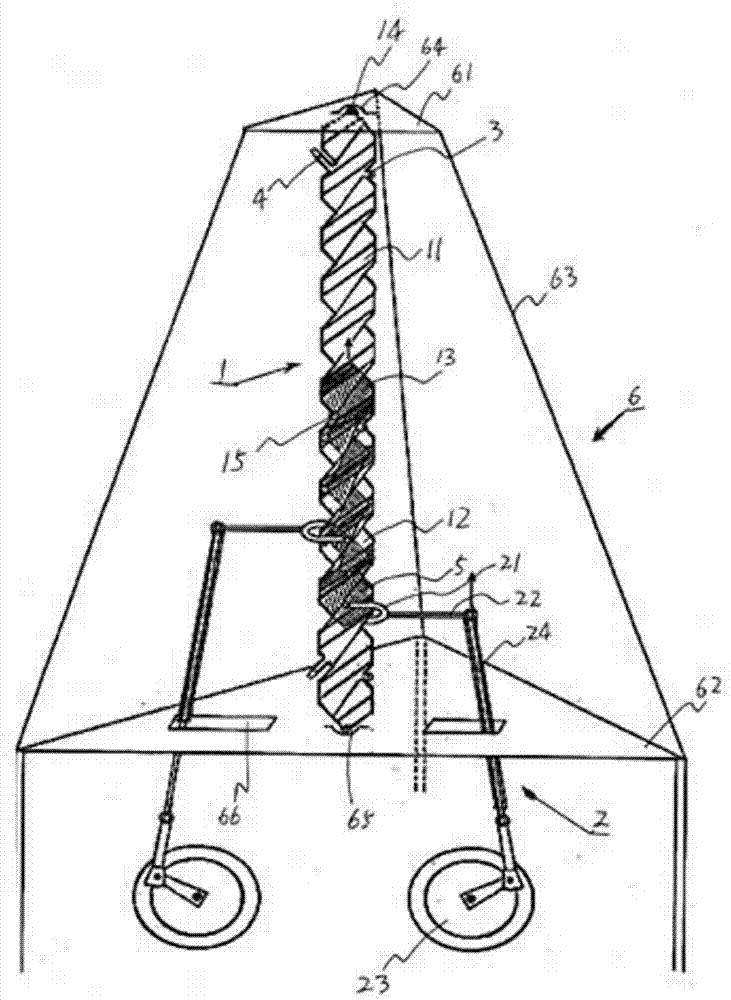

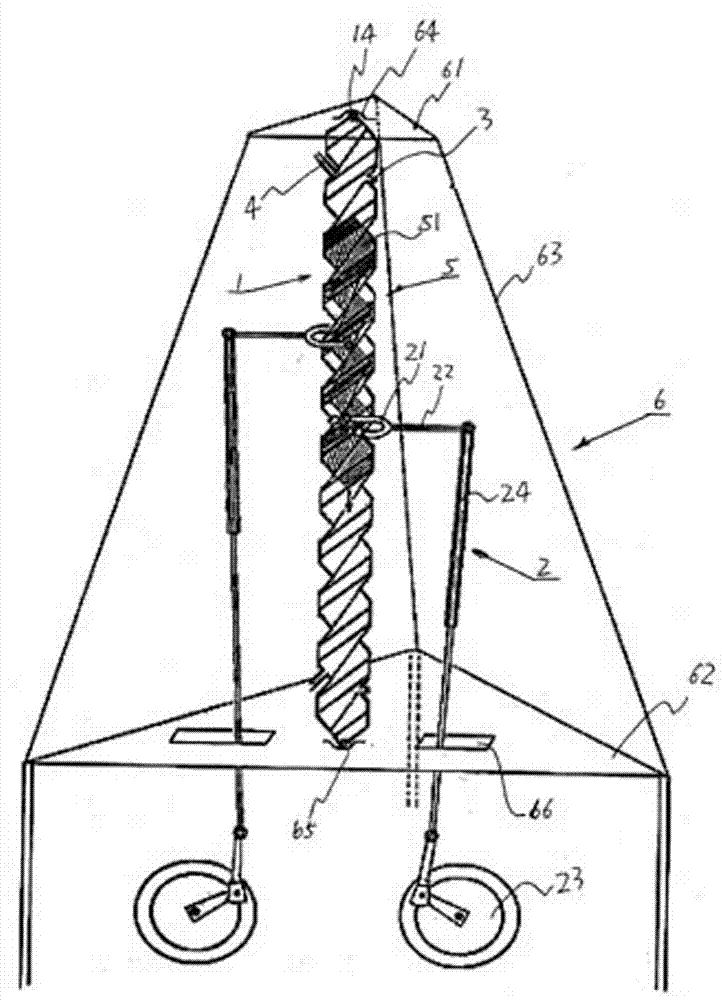

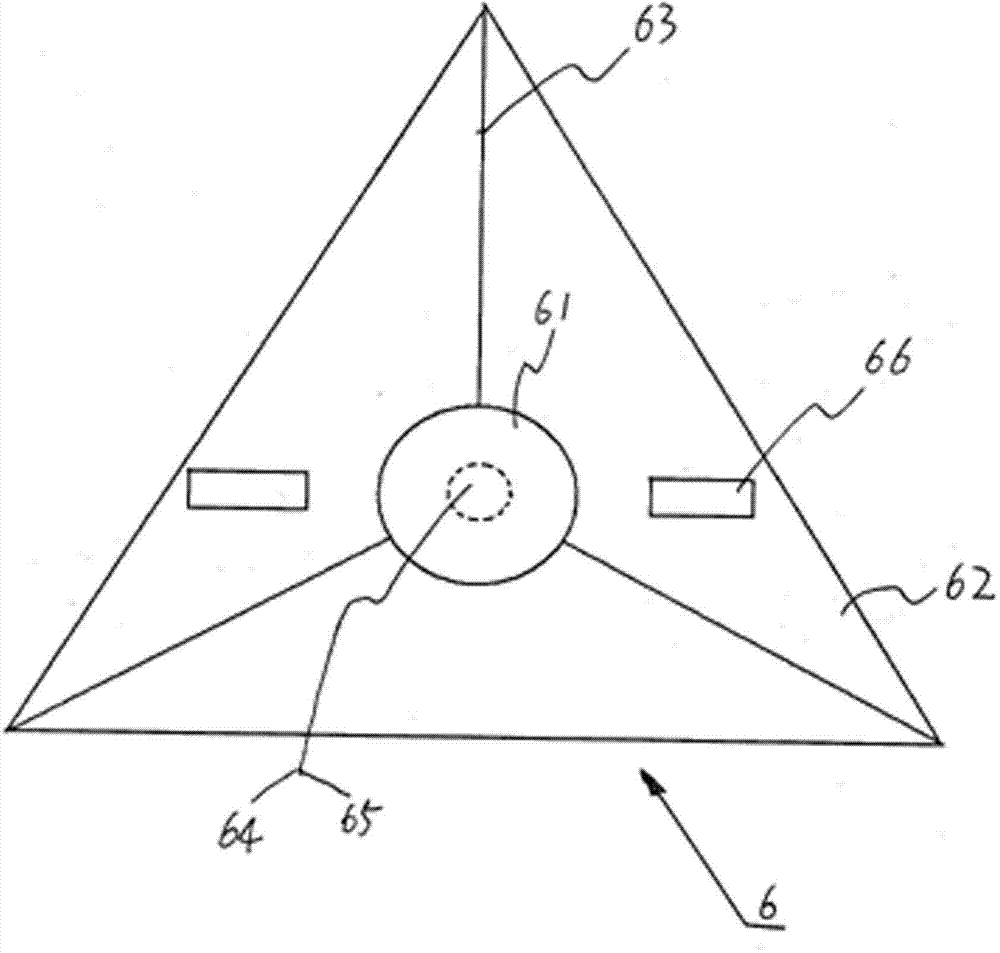

[0023] see Figure 1 to Figure 8 , these six figures provide the appearance structure of the first embodiment of the vacuum screw engine proposed by the present invention. The engine includes a hollow screw 1 , a transmission assembly 2 , an exhaust assembly, a screw driver 5 and a support assembly 6 . The outer surface of the hollow screw 1 is provided with an external thread 11 and the inner surface of the hollow part 12 is provided with an internal thread 13 opposite to the direction of the external thread 11, and balls 14 are respectively installed on the two top ends of the hollow screw 1, and in Both ends of the hollow screw 1 are provided with exhaust components, and a through hole 15 is provided in the middle area of the hollow part 12 . The exhaust assembly is arranged at both ends of the hollow screw 1 and communicates with the hollow part 12 . The exhaust assembly includes air extraction parts 3 and air valves 4 respectively arranged at both ends of the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com