Double-pushing-plate high-temperature sintering kiln for producing vanadium-nitrogen alloy

A high-temperature sintering, double-push plate technology, applied in the field of kiln equipment, can solve the problems of short life, small output, and high energy consumption, and achieve the effects of improving service life, low product unit consumption, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

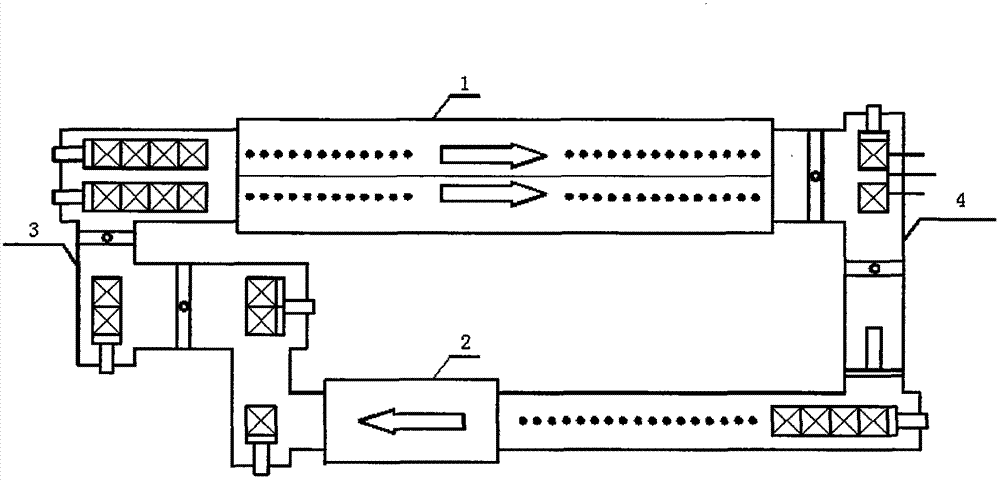

[0009] A double-push-plate high-temperature sintering kiln for producing vanadium-nitrogen alloys of the present invention includes a main kiln 1, an auxiliary kiln 2, a kiln head propulsion mechanism 3, a kiln tail propulsion mechanism 4, an electric heating system, an air intake system, and an exhaust system and control systems, etc.

[0010] Such as figure 1 As shown, the length of the main kiln 1 is set in the range of 10-50 meters according to the output, the effective section of the furnace is set in the range of 720mm-1000mm in width, and 340mm-500mm in height. Sub-reductive nitriding and K removal + / Na + section, high-temperature firing compact section, cooling section for nitrogen fixation, and cooling section.

[0011] The temperature of the primary reduction and drainage section is controlled below 900°C. According to the length of the kiln, it can be divided into 2-6 temperature zones. High-grade electrothermal alloy wires are used to heat and control the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com