Optical fiber vibrating sensor and power transmission line aeolian vibration monitoring system applying the same

A fiber optic vibration and sensor technology, applied in instruments, measuring devices, and using wave/particle radiation, etc., can solve the problems that vibration sensors need on-site power supply, cannot transmit on-site information in real time, and vibration measurement results cannot be transmitted, etc., so as to facilitate long-term monitoring , Improve reliability and stability, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

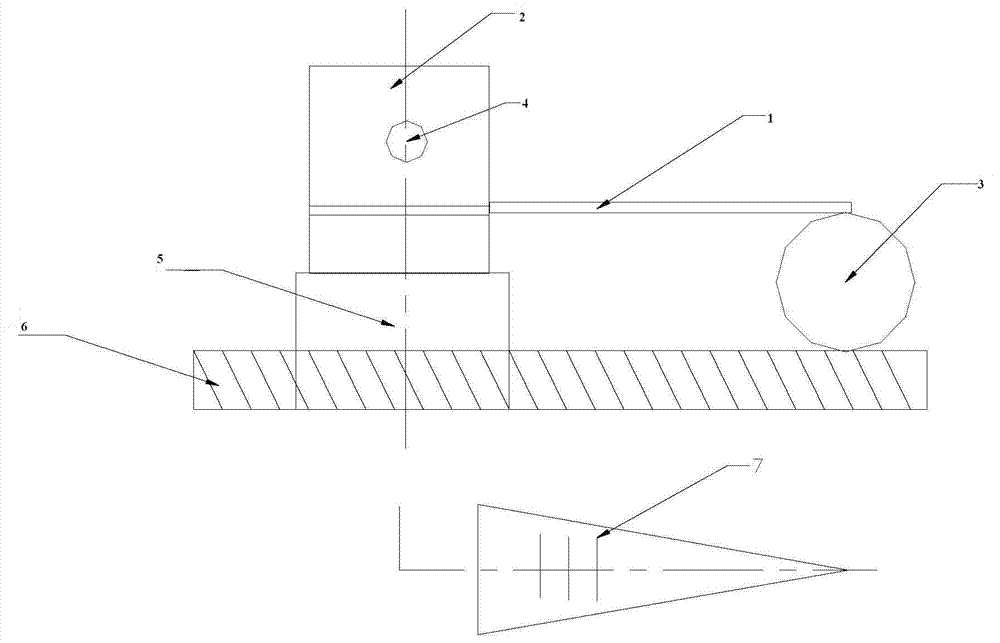

[0030] Such as Figure 1-2 As shown, the optical fiber vibration sensor described in the invention of this example includes equal-intensity beams 1 and fixed bodies 2 connected in sequence, equal-intensity beams 1 and contact bodies 3 arranged on the wires; the fixed body 2 is arranged on the The fixture 5 on the wire 6 is connected to the wire 6, and a fiber Bragg grating 7 is symmetrically pasted on the upper and lower surfaces of the equal-intensity beam 1 perpendicular to the central axis.

[0031] The fixed body 2 is provided with a fiber holder 4, and the fiber end of the fiber Bragg grating 7 passes through the fiber holder 4 and the fiber connector in sequence.

[0032] The equal-strength beam 1 is a cantilever-type elastic body isosceles triangular plate, and its material is preferably beryllium bronze. This material has the advantages of large yield strength, large elastic deformation range, small elastic hysteresis, wear resistance, low temperature resistance, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com