An electromechanical force source device capable of bidirectional loading

A two-way loading, source device technology, applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, instrument, etc. problems such as poor performance, poor loading accuracy, etc., to achieve the effect of shortening production cycle, good reliability, convenient replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

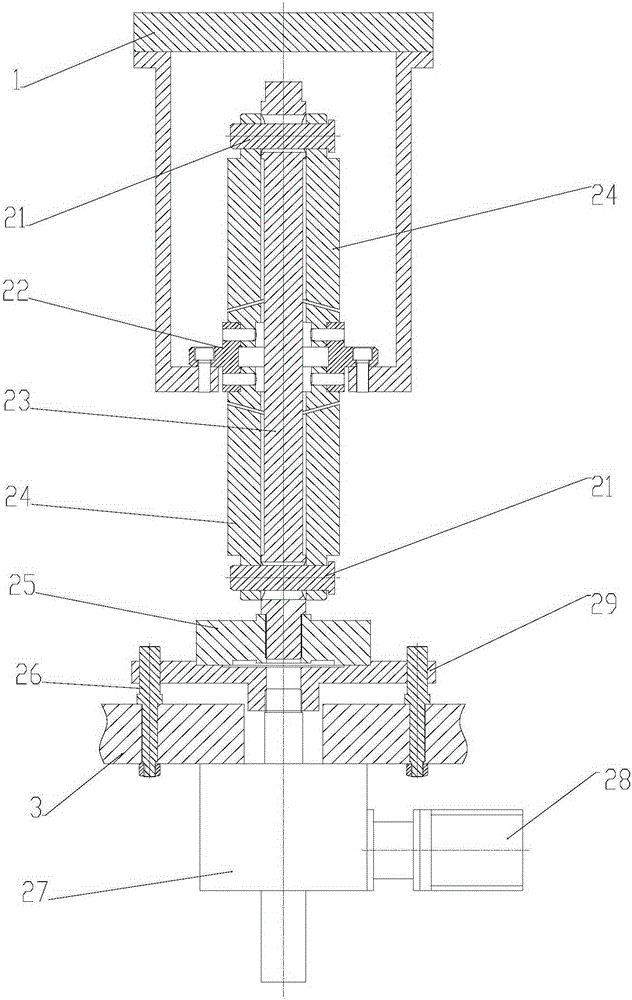

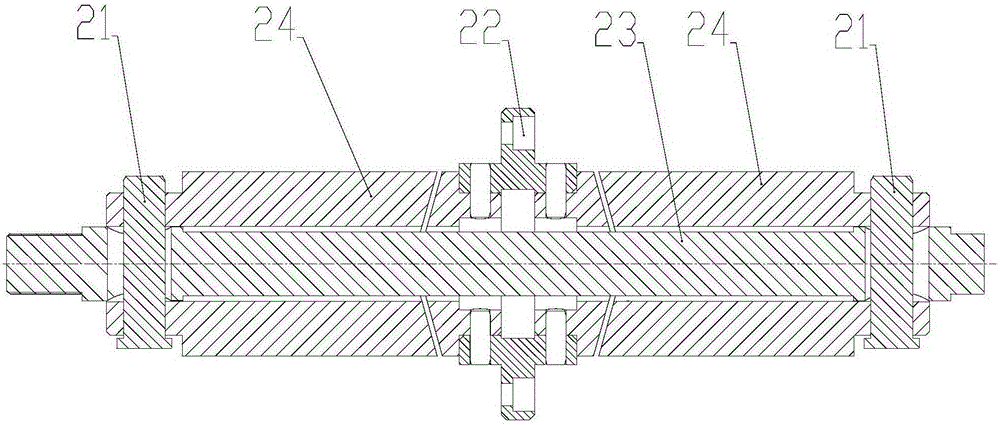

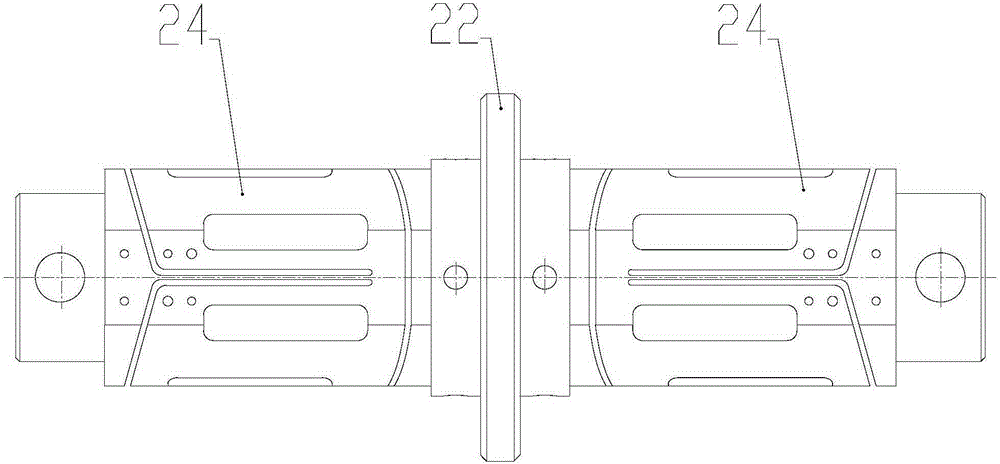

[0030] like figure 1 As shown, the present invention provides an electromechanical high-precision force source device capable of bidirectional loading, including a driving component, a guiding component, a monitoring component, a force transmission component and a loading head 1; the monitoring component is a load cell 25;

[0031] Described driving part comprises servomotor 28 and screw jack 27, and wherein servomotor 28 outputs torque, provides power for the whole power source device, and screw jack 27 converts the rotary motion of servomotor into screw jack screw through its internal worm gear. Axial linear motion, the guide part, detection element and force transmission part are driven by the screw to make linear motion. The servomotor 28 is connected with the screw jack 27 through the intermediate adapter seat and fixed with screws. The output shaft of the servomotor 28 is connected with the input shaft of the screw jack 27 through a coupling to transmit the torque output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com