Bilateral multiple plane inclined wave surface interferometer and its detection method

A technology of wave surface interference and interferometer, which is applied in the field of semiconductor and optical measurement, can solve the problems of unsuitable detection of flat component surface topography, unsuitable flat component detection, error periodic in-situ calibration, etc., to increase the dynamic range of measurement , Improve the measurement yield, the effect of large inclination angle tolerance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to better understand the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

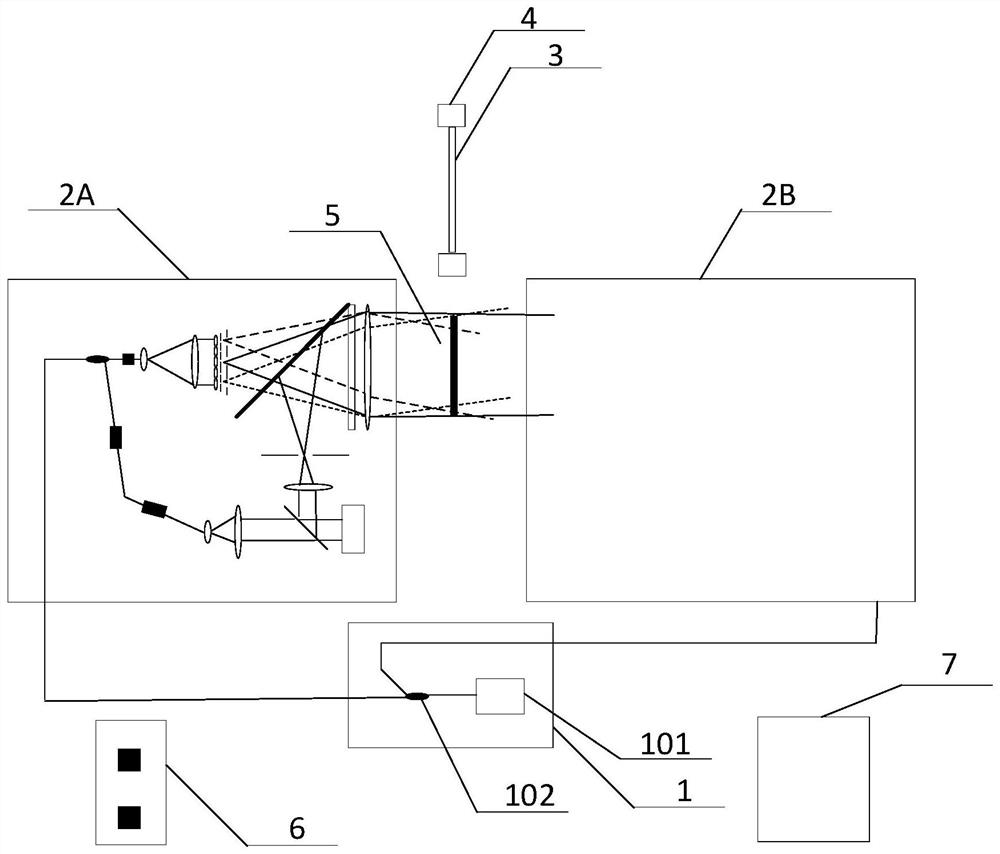

[0077] figure 1 It is a schematic diagram of the invented double-sided multi-plane inclined wave surface interferometer, the system includes a light source module 1, a first interferometer host 2A, a second interferometer host 2B, a double-sided standard plate 3, a double-sided standard plate adjustment frame 4, and a Measuring non-transparent flat plate components 5, single point thickness measuring sensor 6, control processing unit 7;

[0078] The light source module 1 outputs two paths of light, which are respectively input into the first interferometer host 2A and the second interferometer host 2B;

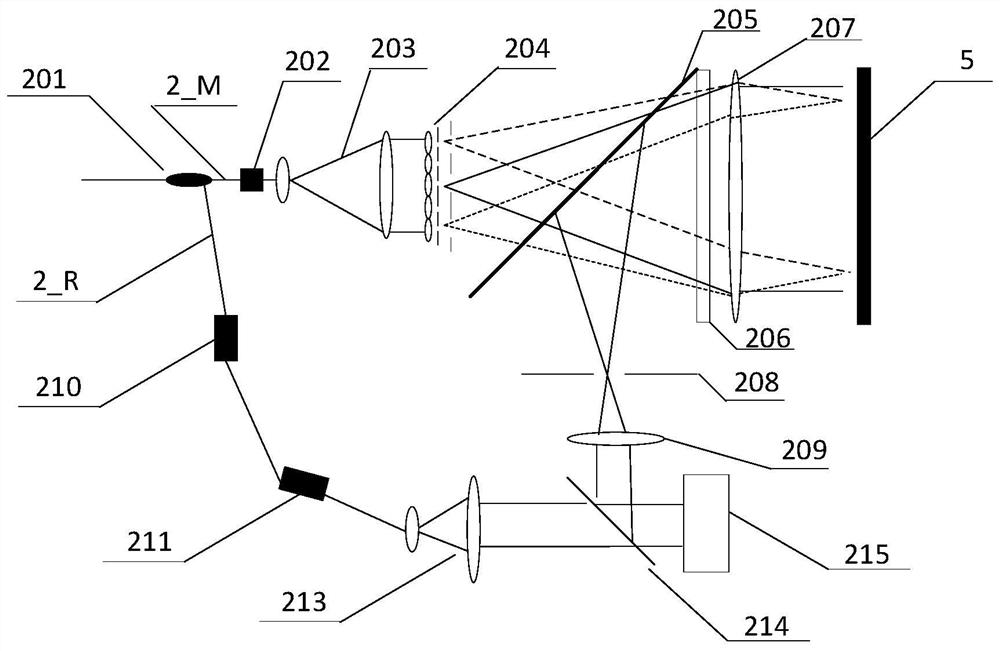

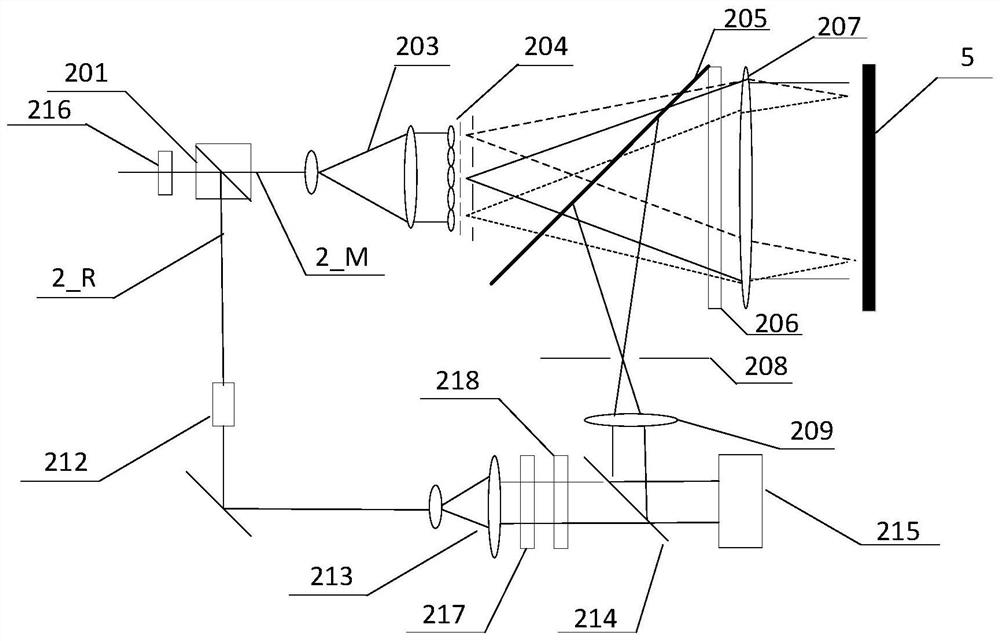

[0079]Both the first interferometer host 2A and the second interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com