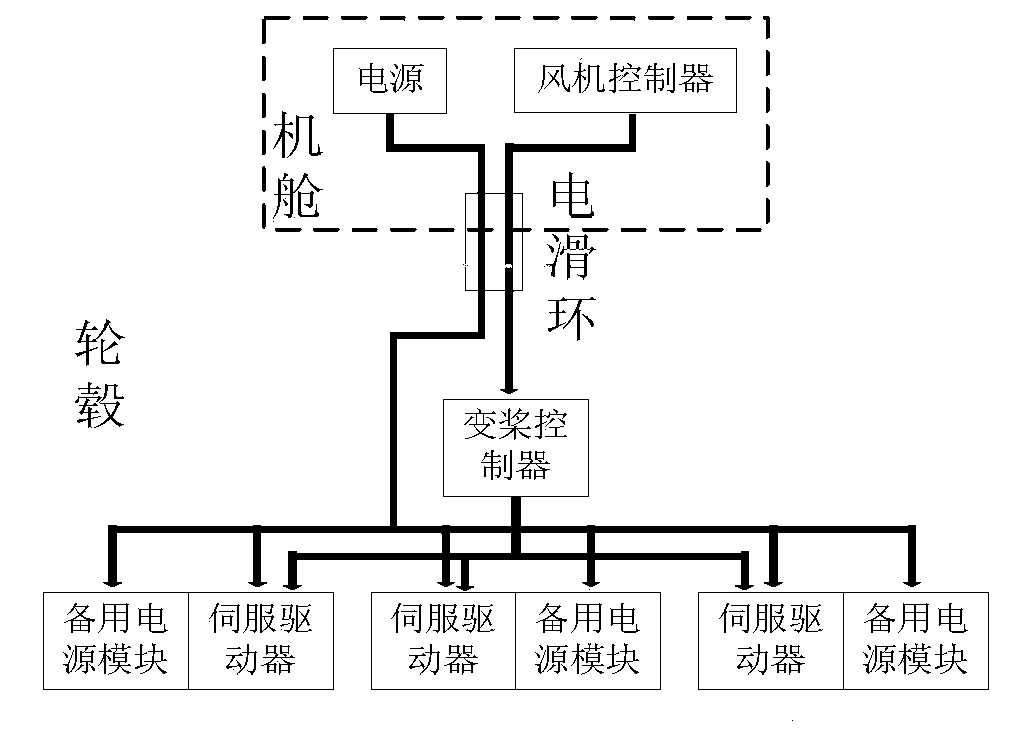

Integrated structure of servo driver and backup power supply for pitch control system

A technology of servo drive and backup power supply, applied in control system, emergency power supply arrangement, AC motor control and other directions, can solve the problems of occupying wheel hub space, complicated connecting lines, many fault points, etc., to achieve firm installation, simplified connection, and internal saving. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

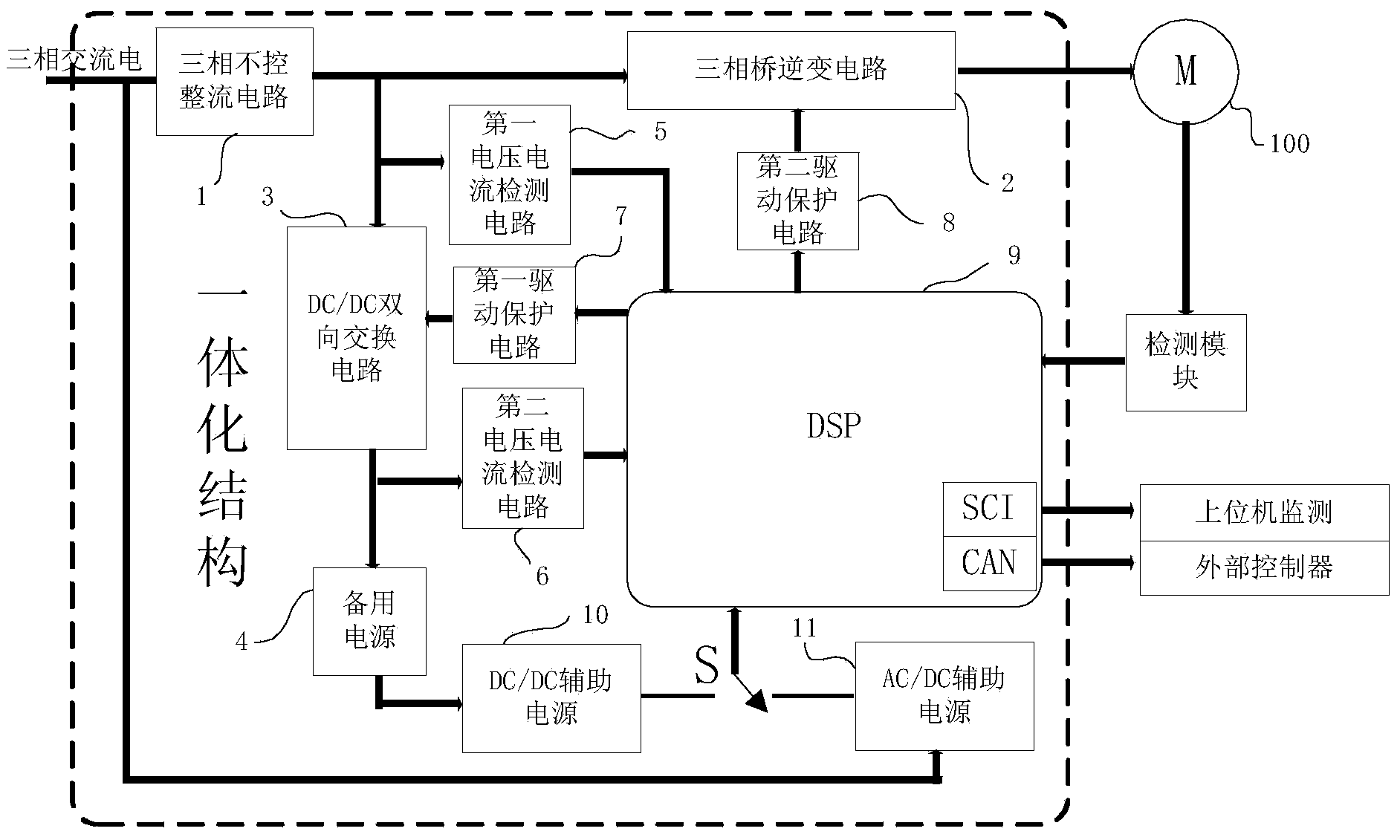

[0030] The present invention will be further described below in conjunction with accompanying drawing.

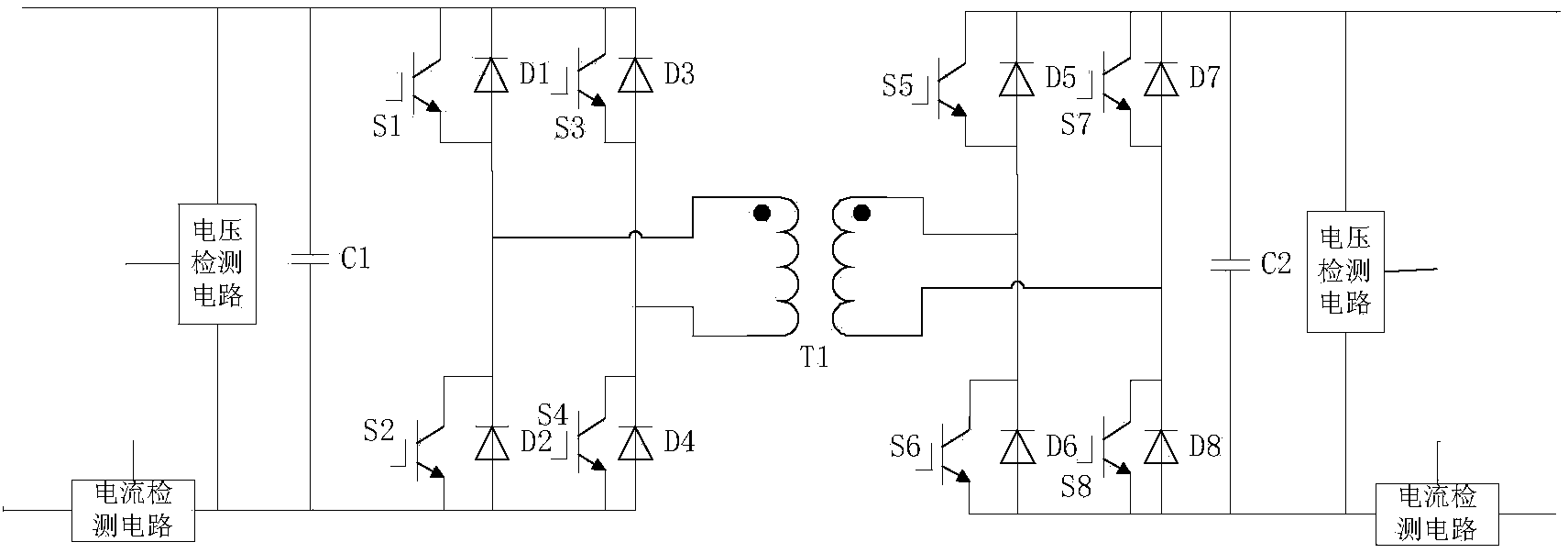

[0031] see figure 2 , the integrated structure of the pitch control system servo driver and backup power supply of the present invention includes a three-phase uncontrolled rectifier circuit 1, a three-phase bridge inverter circuit 2, a DC / DC bidirectional switching circuit 3, a backup power supply 4, a first Voltage and current detection circuit 5, second voltage and current detection circuit 6, first drive protection circuit 7, second drive protection circuit 8, DSP9, DC / DC auxiliary power supply 10, AC / DC auxiliary power supply 11 and single pole double throw switch S, in:

[0032] The input end of the three-phase uncontrolled rectification circuit 1 receives three-phase alternating current, and its output end is respectively connected to the respective input ends of the three-phase bridge inverter circuit 2, the DC / DC bidirectional switching circuit 3 and the first vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com