Sludge crushing system and sludge crushing method

A crushing system and sludge technology, applied in the direction of grain processing, etc., can solve the problems of difficulty in obtaining small-sized particles with a surface area, easy adhesion of sludge, and difficulty in crushing, etc., to achieve simple and easy operation, good crushing effect, and low processing cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

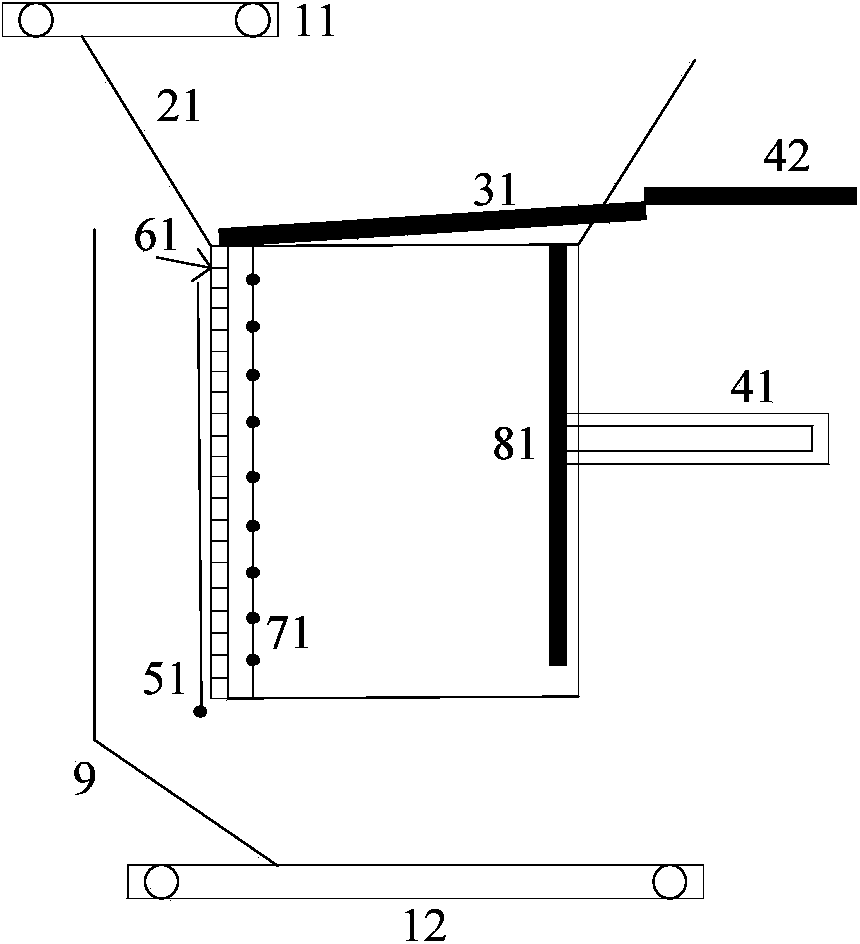

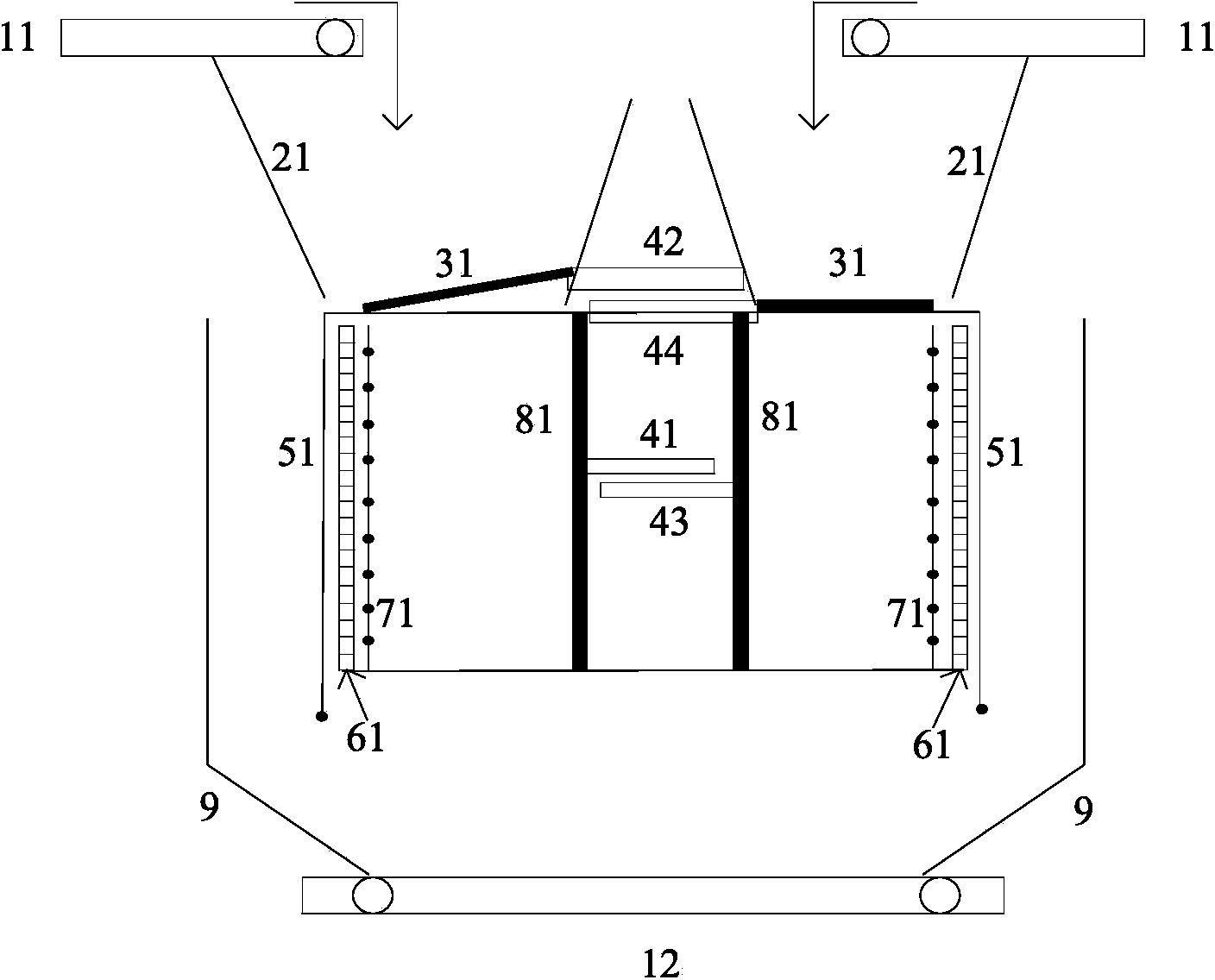

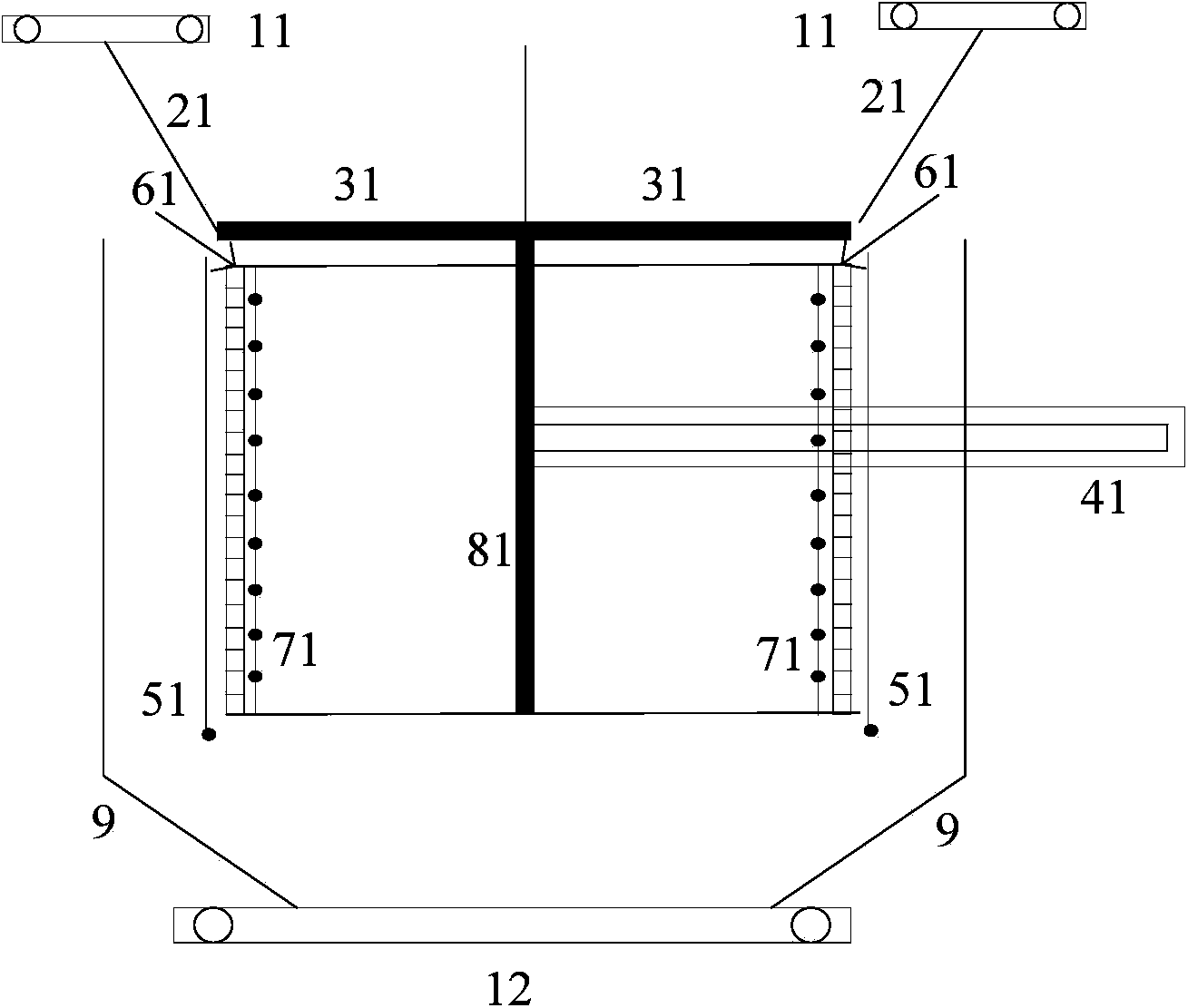

[0030] The following will clearly and completely describe the technical solutions of the embodiments of the present invention in conjunction with the accompanying drawings of the present invention

[0031] For the convenience and clarity of description, the upper, lower, left, right, front, and rear sides described below are the upper, lower, left, right, front, and rear sides shown in the accompanying drawings.

[0032] A sludge crushing system disclosed by the invention is used to realize high-efficiency crushing of sludge that can adapt to a wide range of water content. combine Figure 1 to Figure 4 As shown, it includes a feed conveyor 11, a silo 21, a box body 10, a mud pressing mechanism, a fixed knife group, a moving knife 51 and a material receiving and conveying system. The feed conveyor 11 is used to transport sludge into the silo 21 , Generally, a conveyor belt can be used.

[0033] like figure 1 As shown, the silo 21 is arranged above the box body 10 for storing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com