Preparation method of size-controllable microporous carbon nanorod

A technology of nanorods and microporous carbon, which is applied in the field of preparation of microporous carbon nanorods, which can solve the problems of uncontrollable size of microporous carbon materials, large size of MOF template materials, and long synthesis time, so as to achieve uniform appearance and low cost. Effect of low cost and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

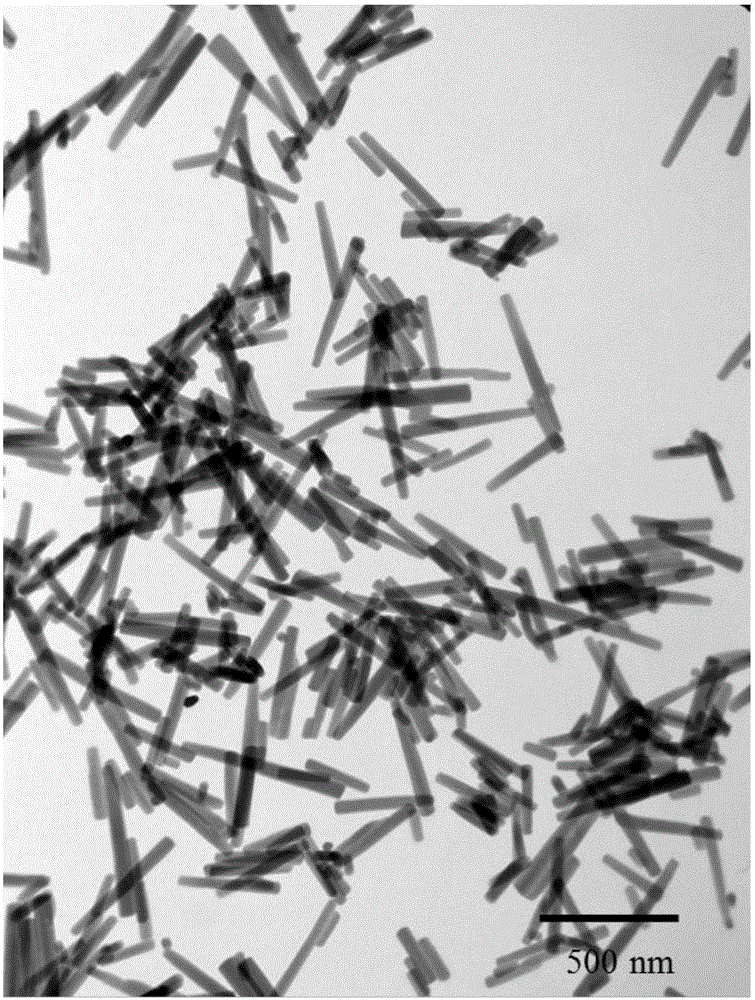

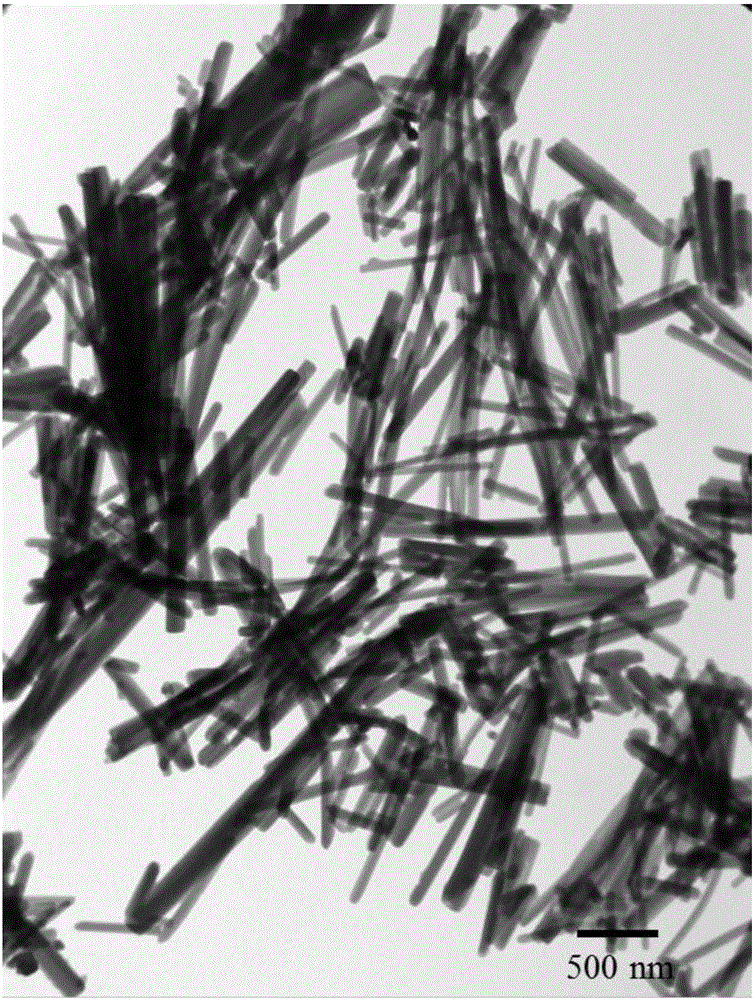

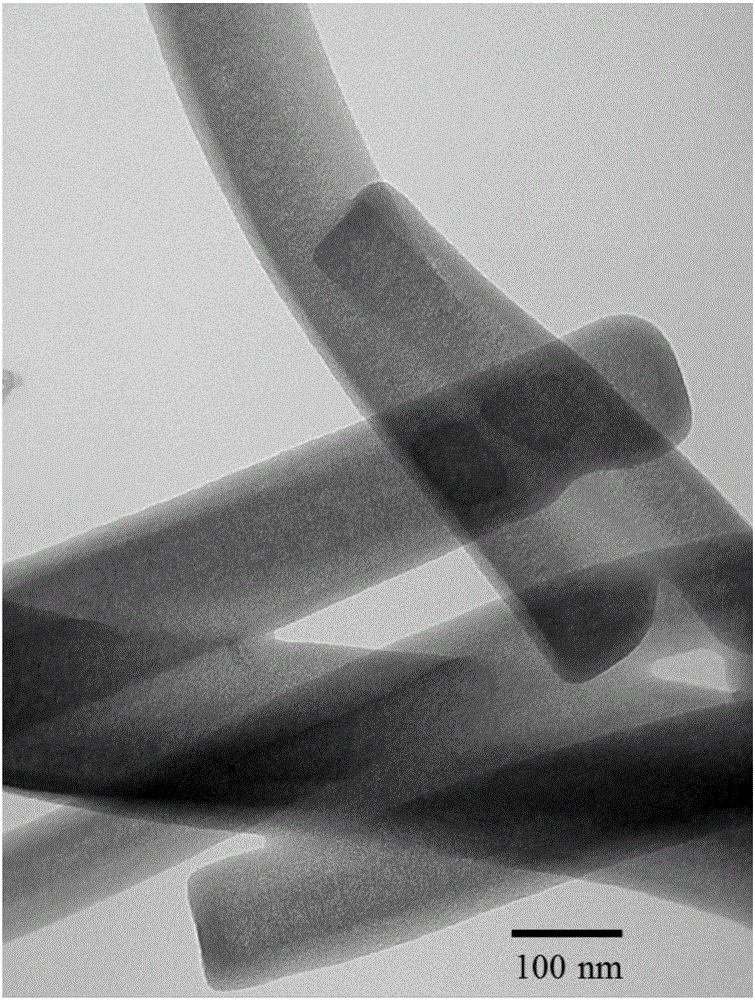

[0026] Mix the ethanol solution of trimesic acid and the aqueous solution of zinc acetate dihydrate, and conduct an ultrasonic reaction at 25° C. for 30 minutes under the conditions of ultrasonic frequency 53 KHz and power 500 W. The molar concentration of trimesic acid is 0.0125mol / L, the molar ratio of trimesic acid to zinc acetate dihydrate is 1:1, and the volume content of water is 12.5%. Centrifuge, wash, and dry to obtain the zinc metal organic framework material; calcinate at 800° C. for 5 h under a nitrogen atmosphere, soak in 10% hydrofluoric acid for 12 h to remove metal oxides, and obtain microporous carbon nanorods.

Embodiment 2

[0028] Mix the ethanol solution of trimesic acid and the aqueous solution of zinc acetate dihydrate, and conduct an ultrasonic reaction at 25° C. for 30 minutes under the conditions of ultrasonic frequency 53 KHz and power 500 W. The molar concentration of trimesic acid is 0.0125mol / L, the molar ratio of trimesic acid to zinc acetate dihydrate is 1:1, and the volume content of water is 25%. Centrifuge, wash, and dry to obtain the zinc metal organic framework material; calcinate at 800° C. for 5 h under a nitrogen atmosphere, soak in 10% hydrofluoric acid for 12 h to remove metal oxides, and obtain microporous carbon nanorods.

Embodiment 3

[0030] Mix the ethanol solution of trimesic acid and the aqueous solution of zinc acetate dihydrate, and conduct an ultrasonic reaction at 25°C for 30 minutes under the conditions of ultrasonic frequency 53KHz and power 500W. The molar concentration of trimesic acid is 0.0125mol / L, the molar ratio of trimesic acid to zinc acetate dihydrate is 1:1, and the volume content of water is 50%. Centrifuge, wash, and dry to obtain the zinc metal organic framework material; calcinate at 800° C. for 5 h under a nitrogen atmosphere, soak in 10% hydrofluoric acid for 12 h to remove metal oxides, and obtain microporous carbon nanorods.

[0031] The difference between embodiment 4-8 and embodiment 1 is shown in the table below:

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com