Lead powder recovery equipment

A technology for recovering equipment and lead powder, which is applied in magnetic separation, solid separation, filtration, etc. It can solve the problems of difficult removal of iron impurities and reduce the cost of production materials, so as to avoid hidden dangers of dust, reduce costs, and facilitate clean production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

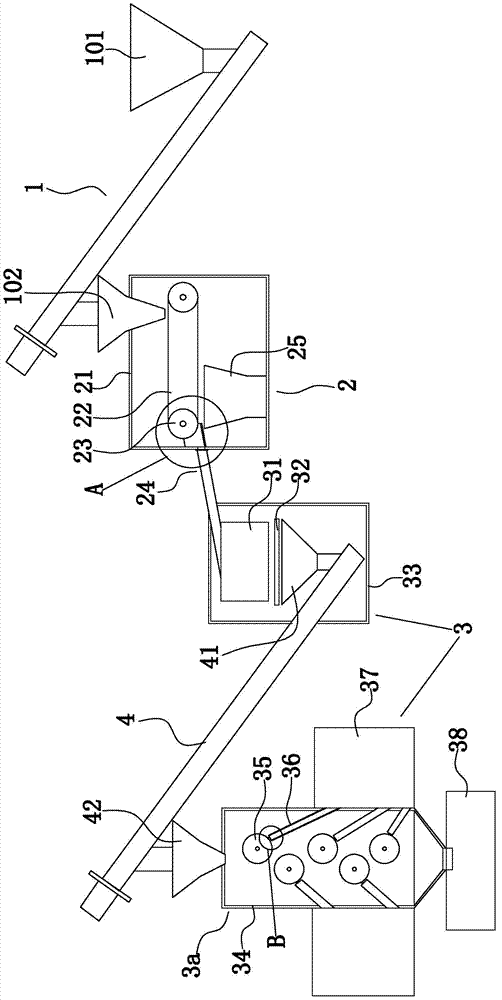

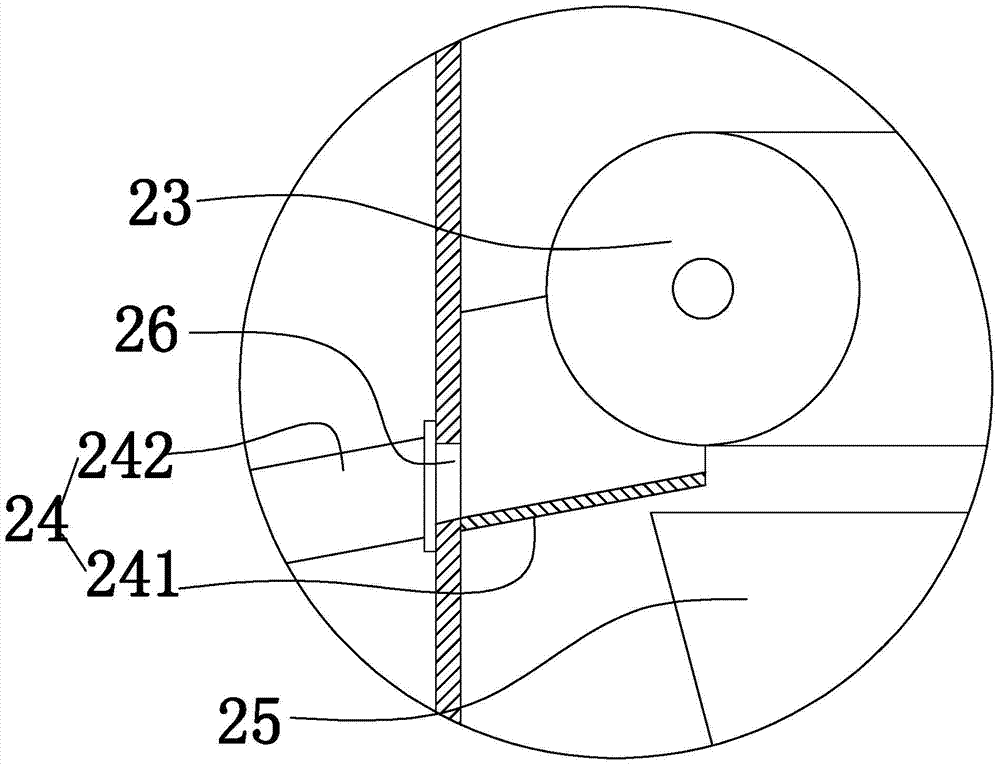

[0039] Embodiment 1: as figure 1 As shown, a lead powder recovery equipment includes a primary filter device 2 for iron impurities and a fine filter device 3 for iron impurities. The primary filter device for iron impurities includes a first screw elevator 1, a first sealed chamber 21, a belt transmission mechanism 22 for conveying lead powder and a lead powder feeder 24 located below the belt transmission mechanism. The belt transmission mechanism is arranged in the first sealed chamber. The belt transmission mechanism comprises two pulleys and a conveyor belt tensioned on the two pulleys. There is a pulley in the two pulleys in the belt transmission mechanism to be the magnetic pulley 23. Magnetic pulley refers to a pulley with magnetism. In the first sealed chamber, an iron impurity recovery frame 25 with an upper end opening is located below the belt transmission mechanism. The iron impurity recovery frame is located between the two pulleys, and the iron impurity recov...

Embodiment 2

[0054] Embodiment 2, the remaining structure of this embodiment is with reference to embodiment 1, and its difference is:

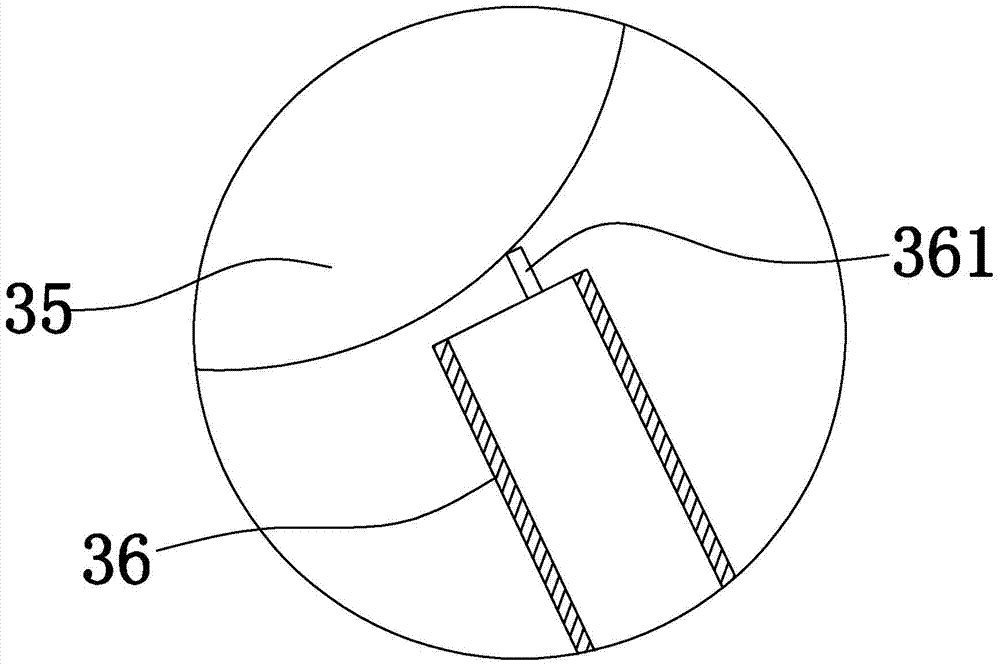

[0055] Such as Figure 4 , Figure 5 As shown, the side walls of the dust raising chamber 3 a are composed of an outer wall 341 and an inner wall 342 . The inner and outer walls are parallel to each other, and there is a gap between the inner and outer walls. On the inner side wall, the positions opposite to the two ends of each magnetic force roller are respectively provided with roller passing holes. The through hole of the roller is a round hole. Spacer sleeves 9 are respectively provided at the through holes of the rollers between the inner and outer walls. The spacer sleeve is arranged coaxially with the through hole of the roller, and the inner diameter of the spacer sleeve communicates with the inner diameter of the through hole of the roller. One end of the spacer is fixed on the inner wall, and the other end is fixed on the outer wall. Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com