Manufacturing method of embedded independent particle shock absorption protection tool materials and shock absorption protection tool

A production method and technology of protective gear, which is applied in the direction of chemical instruments and methods, lamination auxiliary operations, synthetic resin layered products, etc., can solve the problems of low production efficiency in process steps, easy falling off of contained particles, and failure to reach customers, etc. problem, to achieve the effect of shortening the construction period, simple process and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

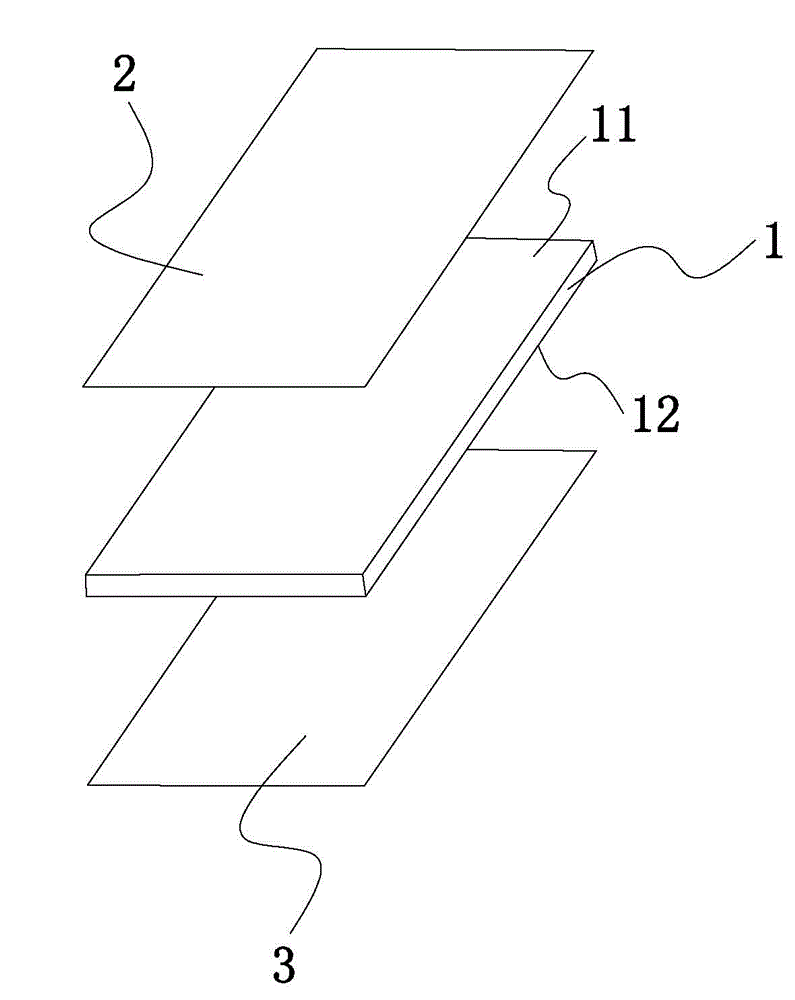

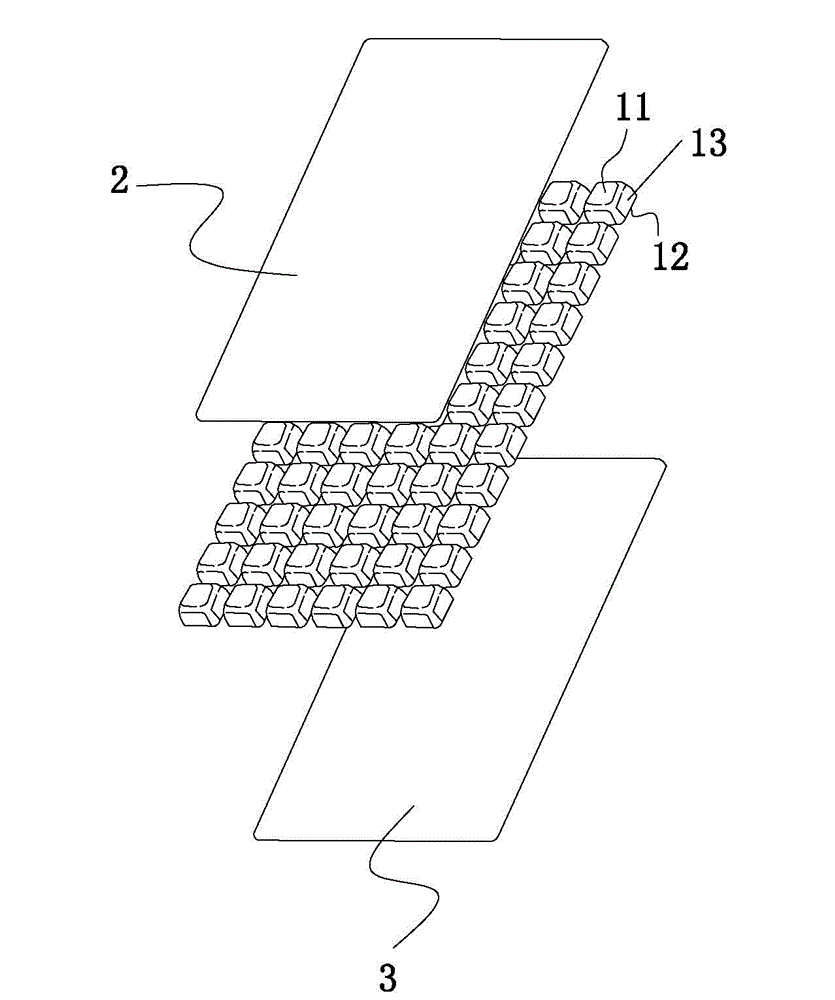

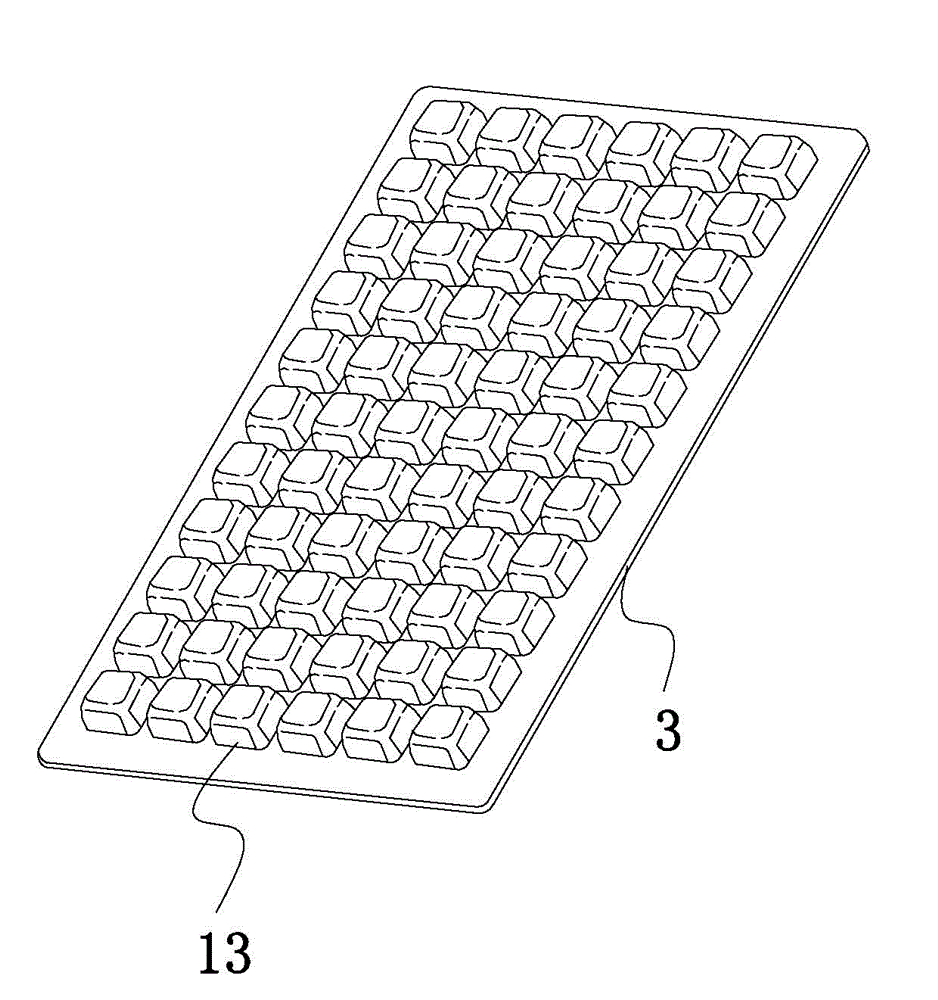

[0029] see figure 1 and figure 2 As shown, the manufacturing method of the embedded independent particle shock-absorbing armor material comprises the following steps:

[0030] In the first step, the low-foaming polyethylene foam raw material is sliced to obtain a buffer board 1, and the buffer board 1 has an upper surface 11 and a lower surface 12;

[0031] In the second step, the buffer plate 1 in the first step above is stamped through a cutting machine and a production mold, and the buffer plate 1 is cut and stamped;

[0032] The third step is to stick the upper surface 11 of the cut-off punched buffer plate 1 on the self-adhesive centrifugal paper 2, and remove the excess material to form independent particles 13;

[0033] The fourth step is to apply glue on the lower surface 12 of the buffer plate 1 made of independent particles 13, and attach or heat press the glued lower surface 12 to the cloth layer 3. During the hot pressing process, the temperature is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com