An automatic rewinding equipment for plastic pipes

A technology for plastic pipes and equipment, applied in the field of plastic pipe rewinding equipment, can solve the problems of high labor intensity, low work efficiency, and parts collision damage for operators, so as to shorten the rewinding time, improve the work efficiency, and change the roll process. smooth and orderly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

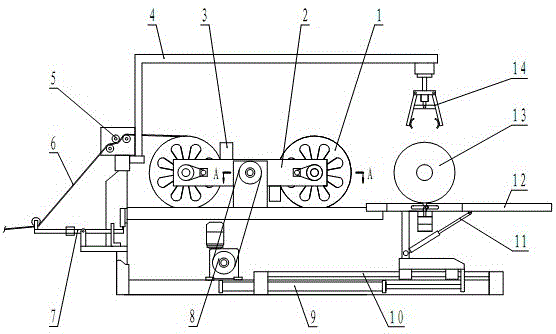

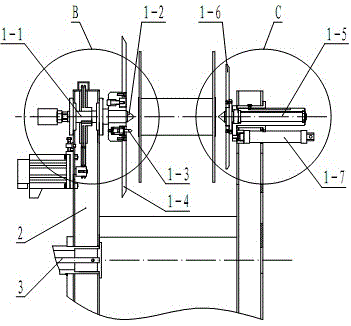

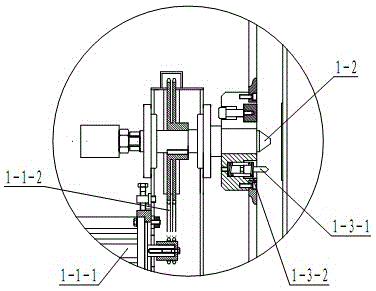

[0030] see figure 1 , Figure 5 , Figure 6 , the present invention includes a main frame 4, a rotating arm 2 installed on the main frame, a pipe arrangement mechanism 5, a tension control mechanism 7, a pipe material cutting mechanism 3, a mobile caliper assembly 14, a movable reel loading and unloading workbench and reel conveying Mechanism 15, the rotating arm 2 is driven by the motor and the transmission assembly 8, two groups of reel assemblies 1 are symmetrically arranged on the rotating arm 2, and one group of reel assemblies is in the winding station, and the The plastic pipe 6 is wound on the reel assembly after passing through the pipe arrangement mechanism 5 and the tension control mechanism 7, and another group of reel assemblies is in the reel changing station, which is connected with the movable caliper assembly 14, the movable reel loading and unloading workbench and the reel assembly. The reel conveying mechanism 15 cooperates to complete the reel changing op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com