Treatment method of heavy metal waste water

A treatment method and technology for heavy metals, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of less heavy metal content reduction and inconspicuous treatment effect, and achieve reduction Effect of Pollution Level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

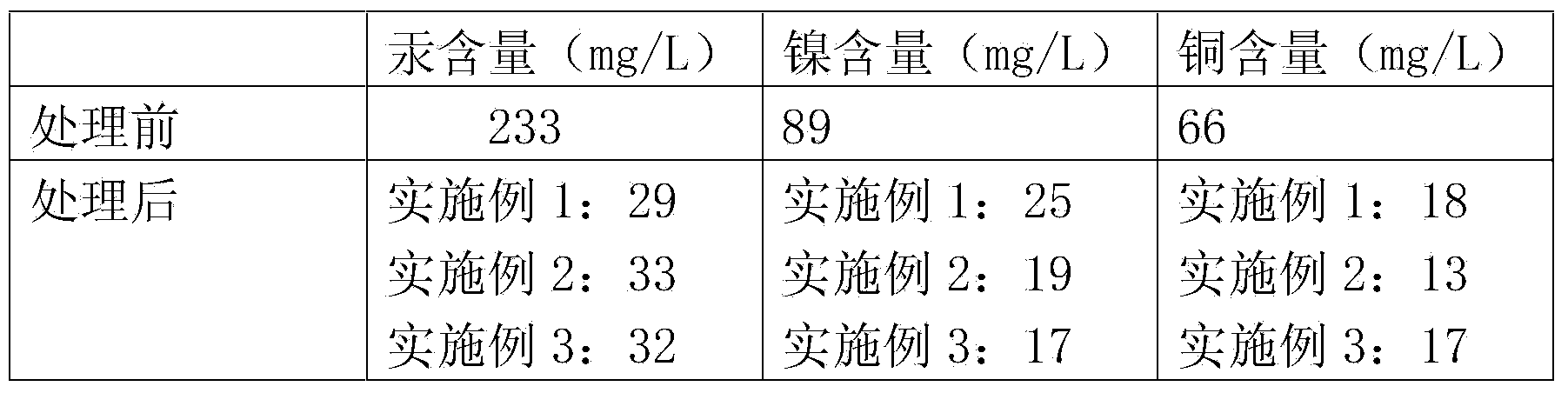

Embodiment 1

[0012] A method for treating heavy metal wastewater, the treatment steps are as follows: (1) Add aluminum tripolyphosphate and carbon black powder to the heavy metal wastewater, the weight of aluminum tripolyphosphate is 3.2wt% of the weight of heavy metal wastewater, and the weight of carbon black is 3.2wt% of the weight of heavy metal wastewater 2.0wt% of the wastewater weight; (2) After adding aluminum tripolyphosphate and carbon black, mechanically stir the heavy metal wastewater, the stirring speed is 80rpm, and the stirring time is 15min; (3) Clarify after the stirring is completed, and take the supernatant; ( 4) After taking the supernatant, put the activated CD-180 macroporous adsorption resin on the heavy metal wastewater, the weight ratio of the supernatant to the wet resin is 10:1, and the sample loading flow rate is 1BV / h; (5) Collect the effluent , and then put the effluent on the D113 cation exchange resin, the ratio of sample volume to resin weight is 6:1, and th...

Embodiment 2

[0014] A treatment method for heavy metal wastewater, the treatment steps are as follows: (1) Add aluminum tripolyphosphate and carbon black powder to the heavy metal wastewater, the weight of aluminum tripolyphosphate is 3.4wt% of the weight of heavy metal wastewater, and the weight of carbon black is 3.4wt% of the weight of heavy metal wastewater 1.5wt% of the wastewater weight; (2) After adding aluminum tripolyphosphate and carbon black, mechanically stir the heavy metal wastewater, the stirring speed is 90rpm, and the stirring time is 20min; (3) Clarify after the stirring, and take the supernatant; ( 4) After taking the supernatant, put the activated CD-180 macroporous adsorption resin on the heavy metal wastewater, the weight ratio of the supernatant to the wet resin is 10:1, and the sample loading flow rate is 2BV / h; (5) Collect the effluent , and then put the effluent on the D113 cation exchange resin, the ratio of sample amount to resin weight is 6:1, and the sample flo...

Embodiment 3

[0016] A method for treating heavy metal wastewater, the treatment steps are as follows: (1) Add aluminum tripolyphosphate and carbon black powder to heavy metal wastewater, the weight of aluminum tripolyphosphate is 3.5wt% of the weight of heavy metal wastewater, and the weight of carbon black is 3.5wt% of the weight of heavy metal wastewater 1.7wt% of the wastewater weight; (2) After adding aluminum tripolyphosphate and carbon black, mechanically stir the heavy metal wastewater, the stirring speed is 85rpm, and the stirring time is 25min; (3) Clarify after stirring, and take the supernatant; ( 4) After taking the supernatant, put the activated CD-180 macroporous adsorption resin on the heavy metal wastewater. The weight ratio of the supernatant to the wet resin is 10:1, and the flow rate of the sample is 2.5BV / h; (5) Collect the outflow Then put the effluent on the D113 cation exchange resin, the ratio of sample volume to resin weight is 6:1, and the sample loading flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com