Novel cathode magnetic steel

A magnetic steel and cathode technology, applied in the field of sputtering coating, can solve the problems of insufficient rigidity of the cathode magnetic steel and the influence of the uniformity of the magnetic steel, and achieve the effect of improving the overall stiffness and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

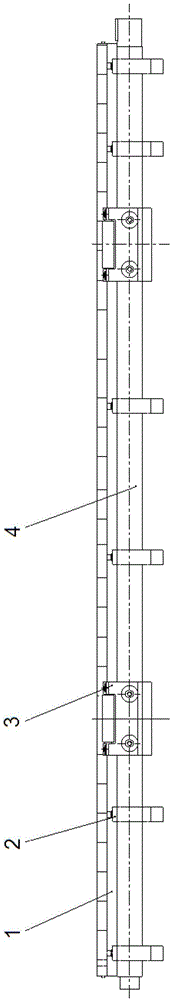

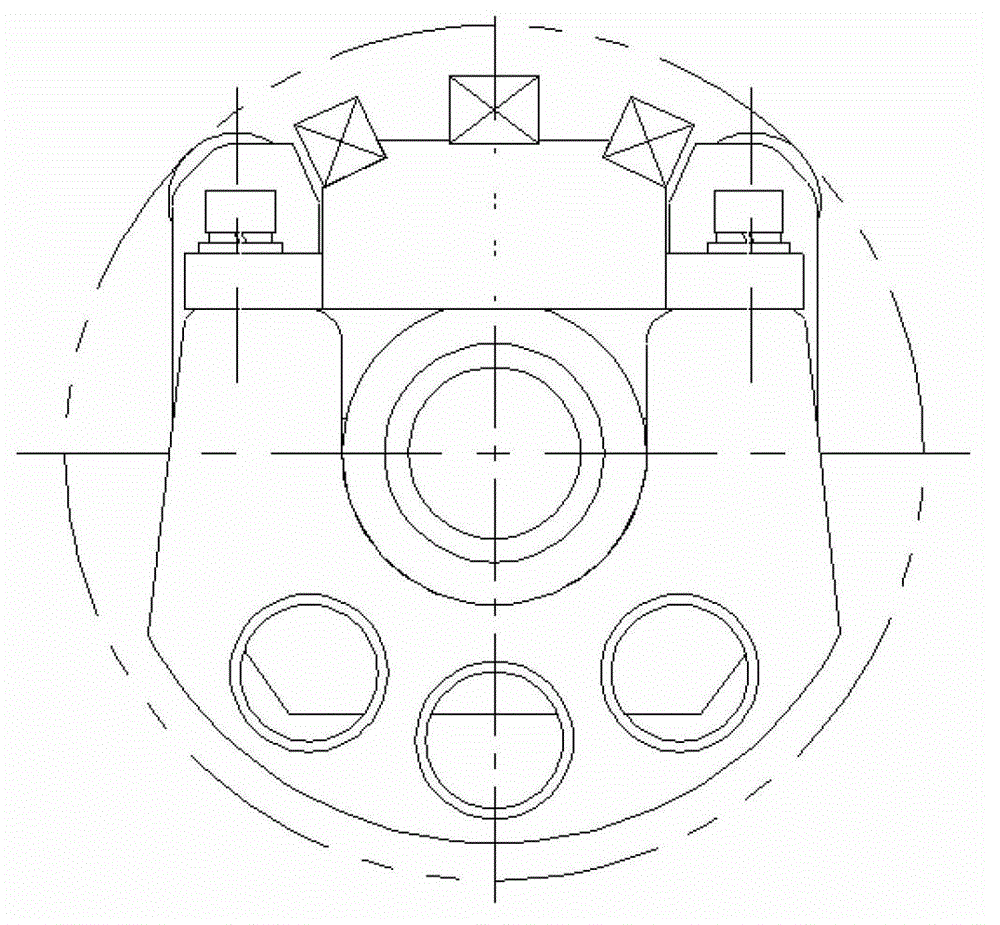

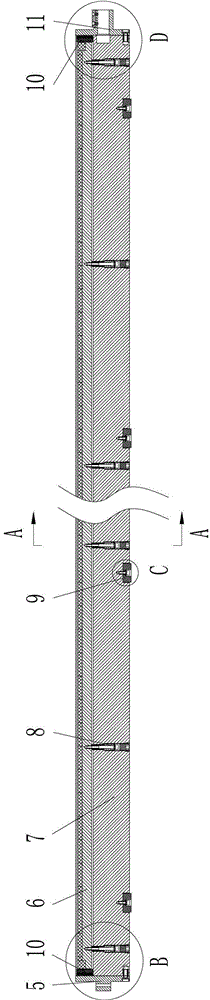

[0028] In the first embodiment of the present invention, please continue to refer to Figure 3 to Figure 7 shown. The above-mentioned supporting base 7 is an aluminum profile supporting base, and an inner cavity is provided on the upper part of the supporting base 7 , which is matched with the magnetic steel assembly 6 , so that the magnetic steel assembly 6 is arranged in the inner cavity of the supporting base 7 .

[0029] In the second embodiment of the present invention, the above-mentioned sealing device 10 is a sealing plate. The magnetic steel assembly 6 is isolated from the outside world by means of a sealing plate installed at both ends of the magnetic steel assembly 6 .

[0030] In the third embodiment of the present invention, several connecting pieces 8 are also included, and the connecting pieces 8 can be screws. Each connecting piece 8 is spaced apart from the lower end of the support base 7 and connected to the magnetic steel assembly 6 , so that the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com