Bamboo Fiber Sheet

A bamboo fiber and sheet technology, applied in the direction of textiles and papermaking, non-woody plant/crop pulp, etc., can solve problems such as difficulty in ensuring strength and rigidity, and achieve the effect of reducing environmental burden, reducing quantity and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

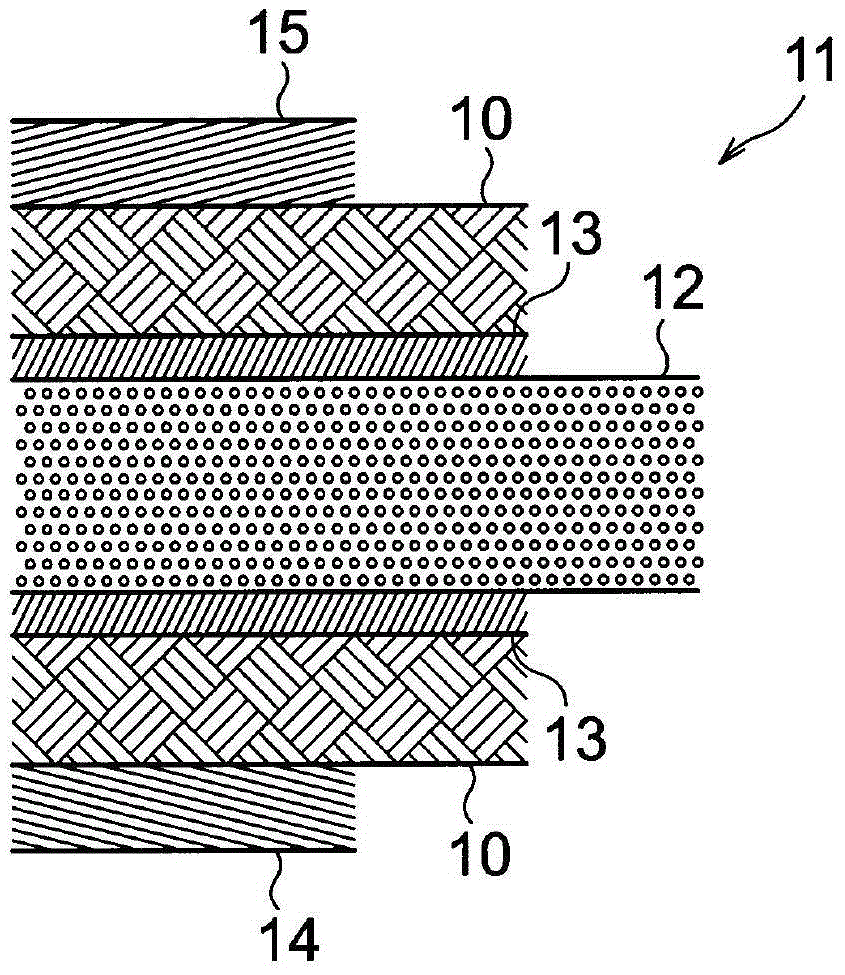

[0057] Now, the bamboo fiber sheet, the manufacturing method of the bamboo fiber sheet, and the vehicle interior substrate to which the bamboo fiber sheet is applied will be described with reference to the accompanying drawings. In addition, the embodiments shown below are merely examples, and it is not intended to exclude various modifications and technical applications not explicitly described in the following embodiments. The structures of this embodiment can be modified in various ways without departing from their gist, and can be selected or combined as needed.

[0058] [1.Bamboo fiber]

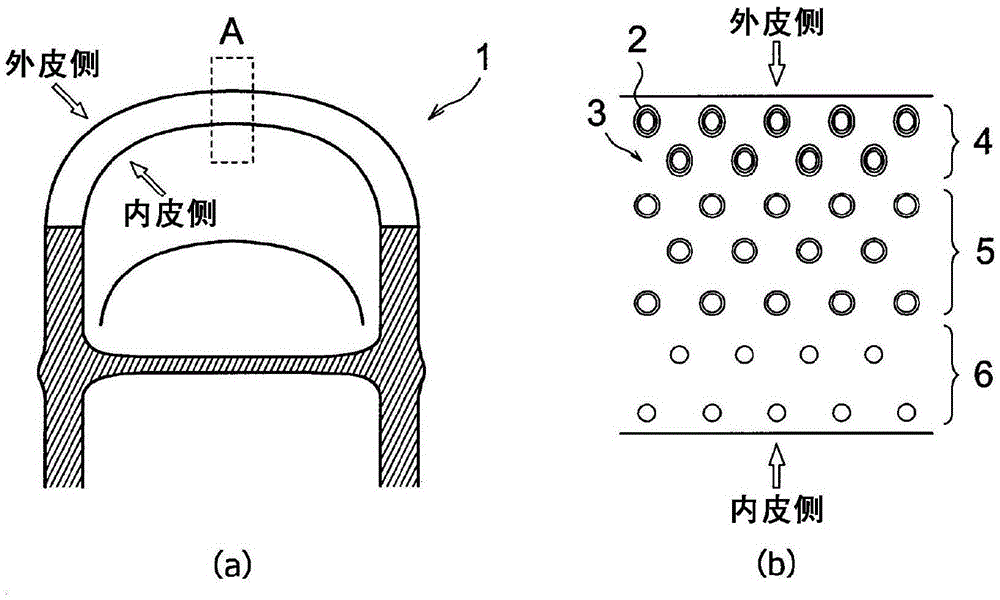

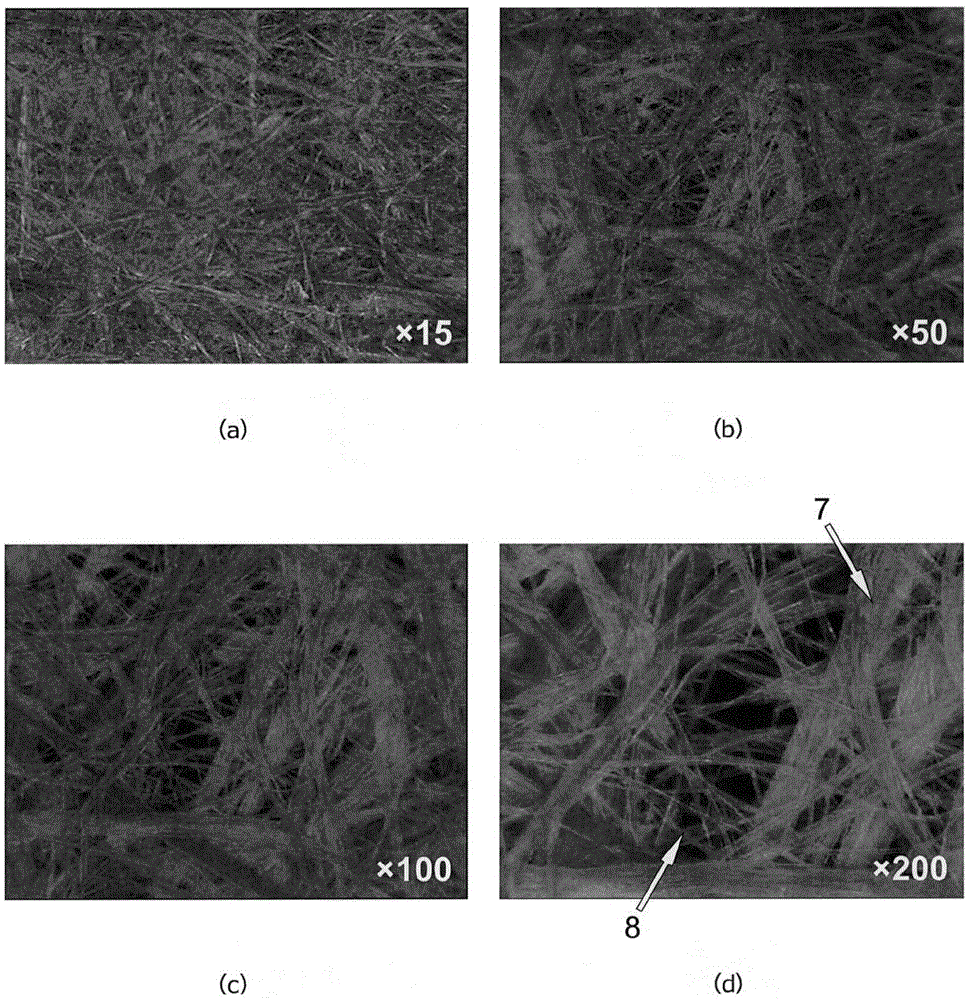

[0059] The bamboo fiber sheet 10 of this embodiment is manufactured using the fiber of bamboo 1 (bamboo fiber) as a raw material. The main component of bamboo fiber is mainly the vascular bundle 2 of bamboo 1. The vascular bundle 2 is a well-developed columnar or polygonal columnar tissue for protecting conduits and screens, and is formed along the extending direction of the bamboo 1 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com