Fixed-point lifting type bridge erection machine and bridge erection method

A bridge erecting machine and a hoisting technology are applied in the field of fixed-point hoisting bridge erecting machines and bridge erecting to achieve the effects of reduced energy consumption, low energy consumption and safe erection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the specific embodiments do not limit the protection scope of the claims of the application.

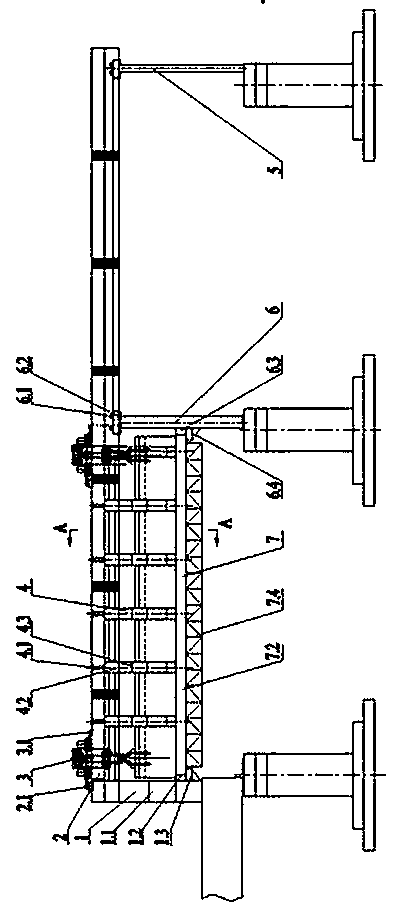

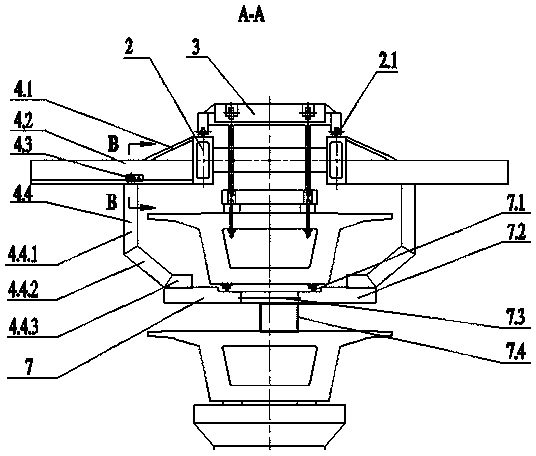

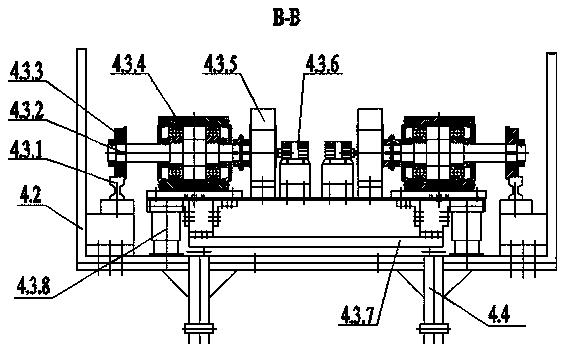

[0034] The fixed-point lifting bridge erecting machine designed by the present invention (bridging machine for short, see figure 1 -4) The design idea is: used for fixed-point lifting bridge erecting machine, two-span structure, push beam design, the push beam uses hydraulic pressure as the power source, pushes the prefabricated box girder to move forward and feed the beam to the designated position, Then carry out the beam lifting, and after the sideways movement of the pushing beam channel is completed, the processes of dropping the beam, closing up and passing the hole will be carried out.

[0035] The bridge erecting machine of the present invention is characterized in that the bridge erecting machine is mainly composed of main girder 2, front outrigger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com