Construction method for improving waterproof effect of coiled materials

A construction method and an improved technology, which can be applied to building insulation materials, infrastructure engineering, roofs using flexible materials, etc., can solve problems such as the inability to prevent the formation of waterlines at lap joints and increase costs, so as to eliminate hidden dangers of water leakage, Increase the cost and ensure the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described in detail below, and the following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

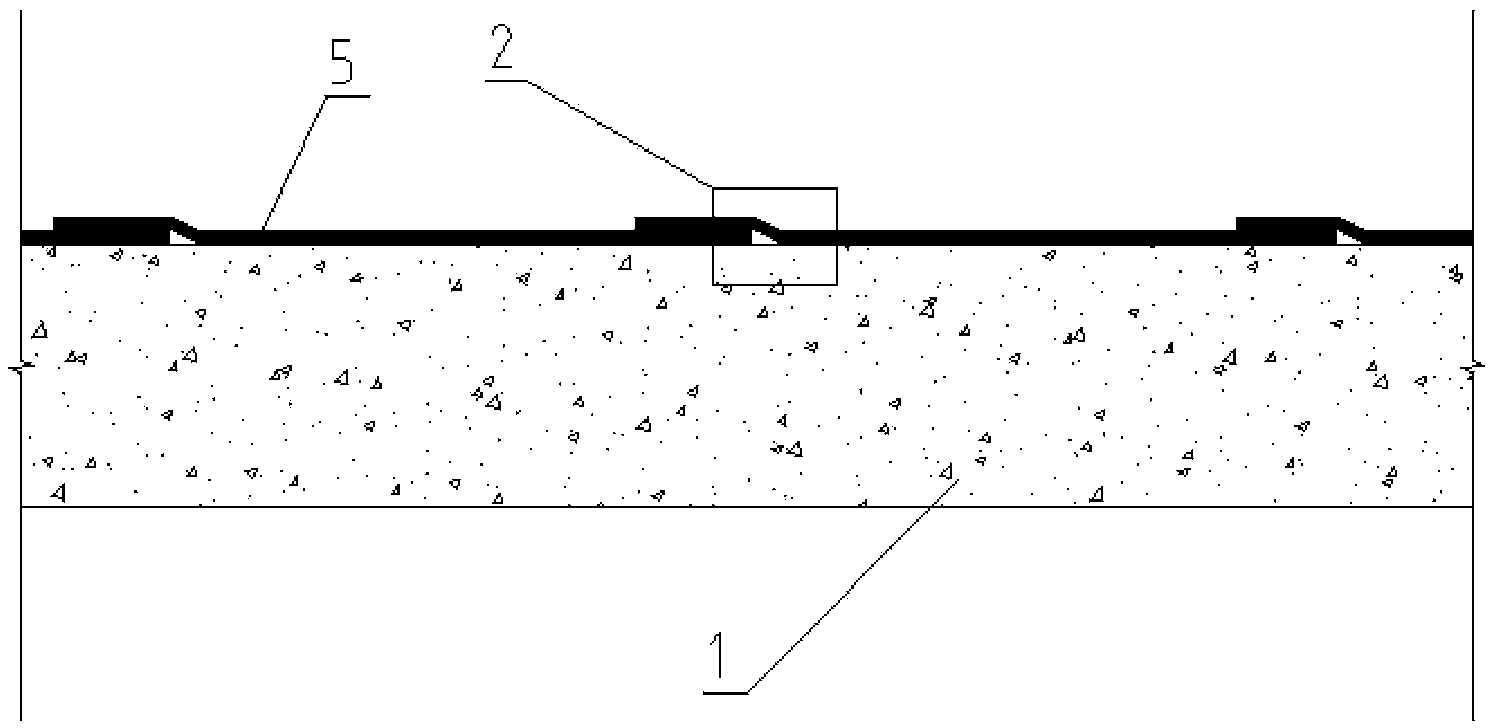

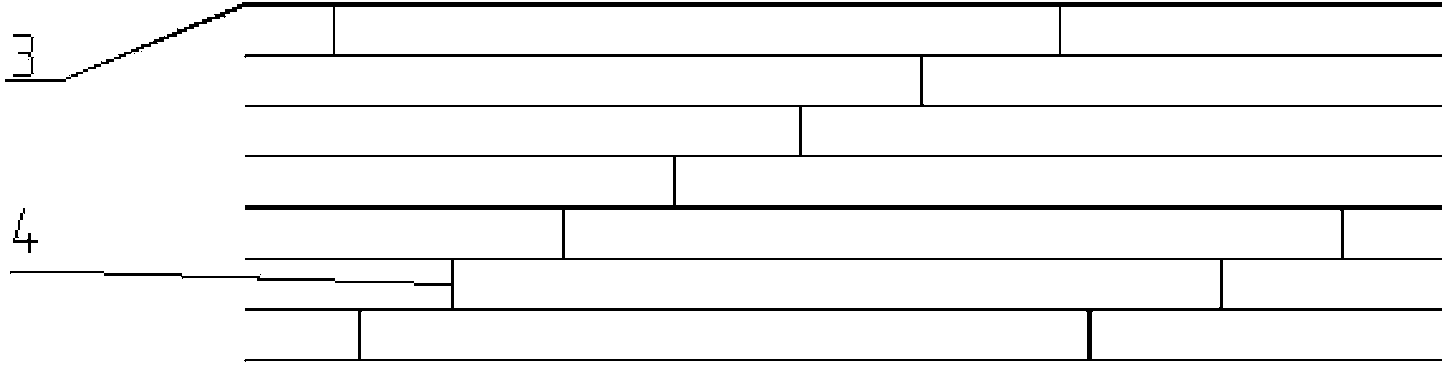

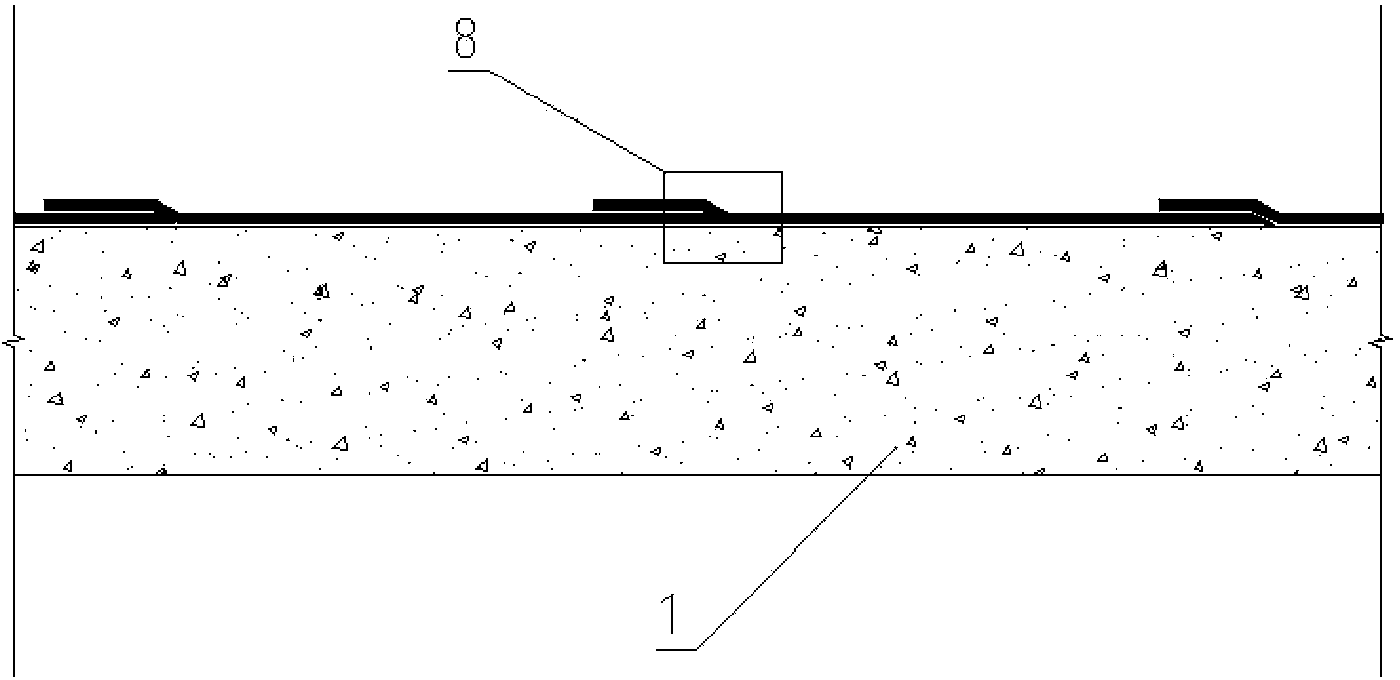

[0025] Such as image 3 and Figure 4 As shown, this embodiment discloses an improved waterproof construction method for coiled materials. The method is mainly based on the traditional coiled material construction process, and a simple soldering iron 7 is made by self-made. heat, and then use a preheated soldering iron 7 to iron out an inclination angle on the overlapping edge 6 of the lower waterproof coiled material 5 at the overlapping position, so that the lower waterproof coiled material 5 and the upper waterproof coiled material 5 at the overlapped position form a closed section 8.

[0026] The specific process is as follows:

[0027] (1) Cleaning of concrete base 1: Clean up the qualified concrete base 1 before construction.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com