Air-operated machine

A technology for wind turbines and fan shafts, which is used in wind turbines, engines, machines/engines, etc., can solve the problems of small wind direction adjustment plate range, small force area of wind blades, and high wind direction requirements, so as to improve reliability and air resistance. The effect of increased, high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

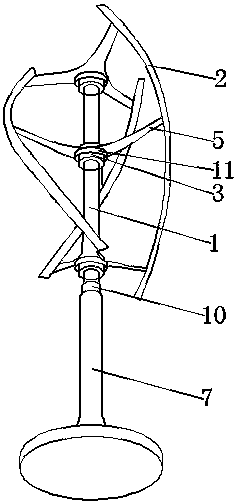

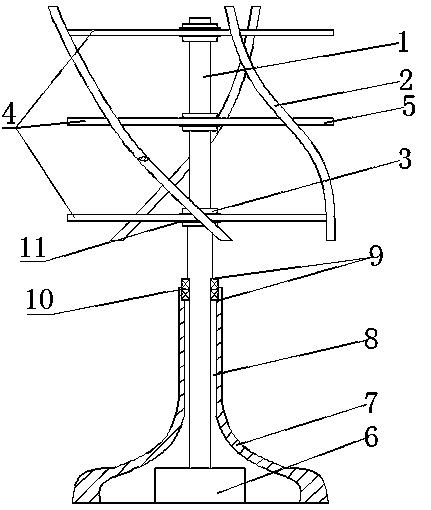

[0018] Such as figure 1 with figure 2 As shown, a kind of wind machine comprises fan shaft 1, blade 2, and described fan shaft 1 is long straight cylindrical rod, and described fan shaft 1 is provided with disc drive machine 3, and described disc drive machine 3 and The support frame 4 is connected, and the support frame 4 is composed of three fan blades 5 placed equidistantly, and the clockwise circular axis offset angle between the adjacent fan blades 5 is 28 ° ~ 32 °, the three support frame 4 Each fan blade 5 is vertically connected to the blade 2 in turn, and the blade 2 is a curved long plate with an airfoil section, and the circumferential angle between the two adjacent blades is 119° to 121°, and the lower end of the fan shaft 1 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com