Combined firework outer barrel

A technology of combining fireworks and outer cylinders, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve problems such as the inability of the propellant combustion chamber to be tightly sealed, damage to the integrity of the outer cylinder body structure, and inconsistent launch heights. Efficient mechanized production, avoiding emission energy loss, and realizing the effect of mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

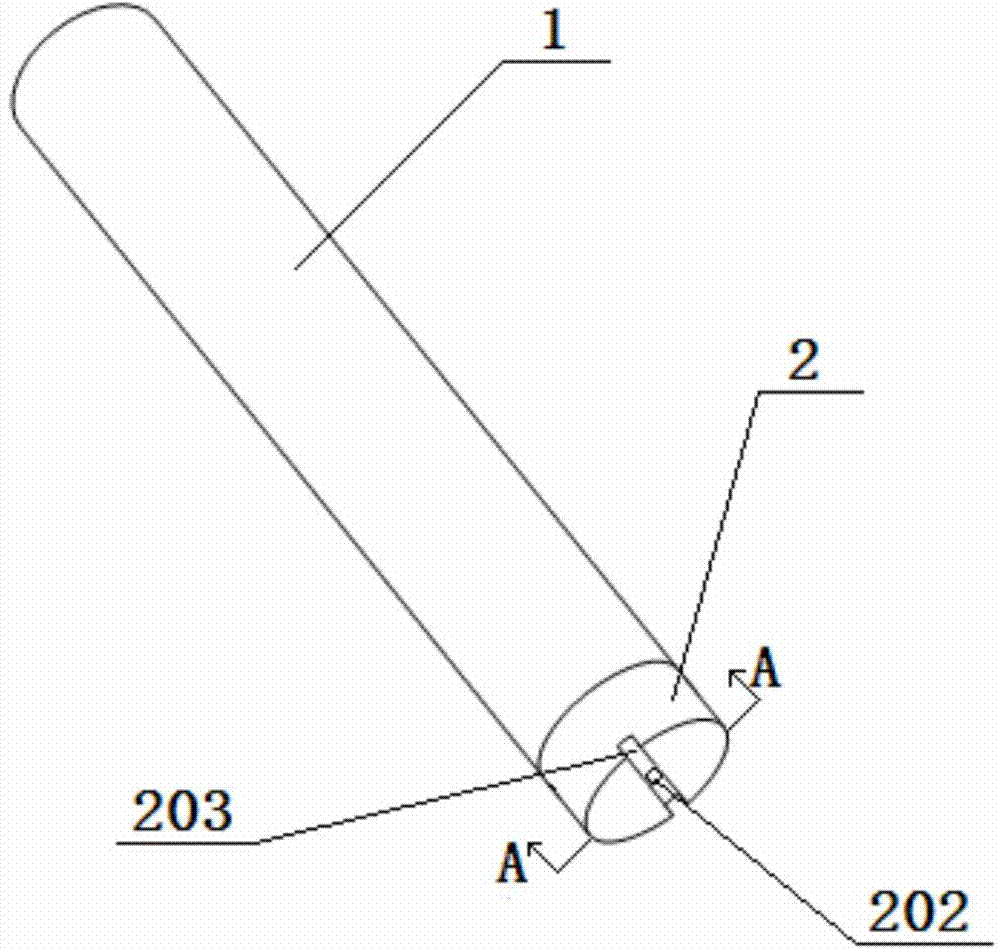

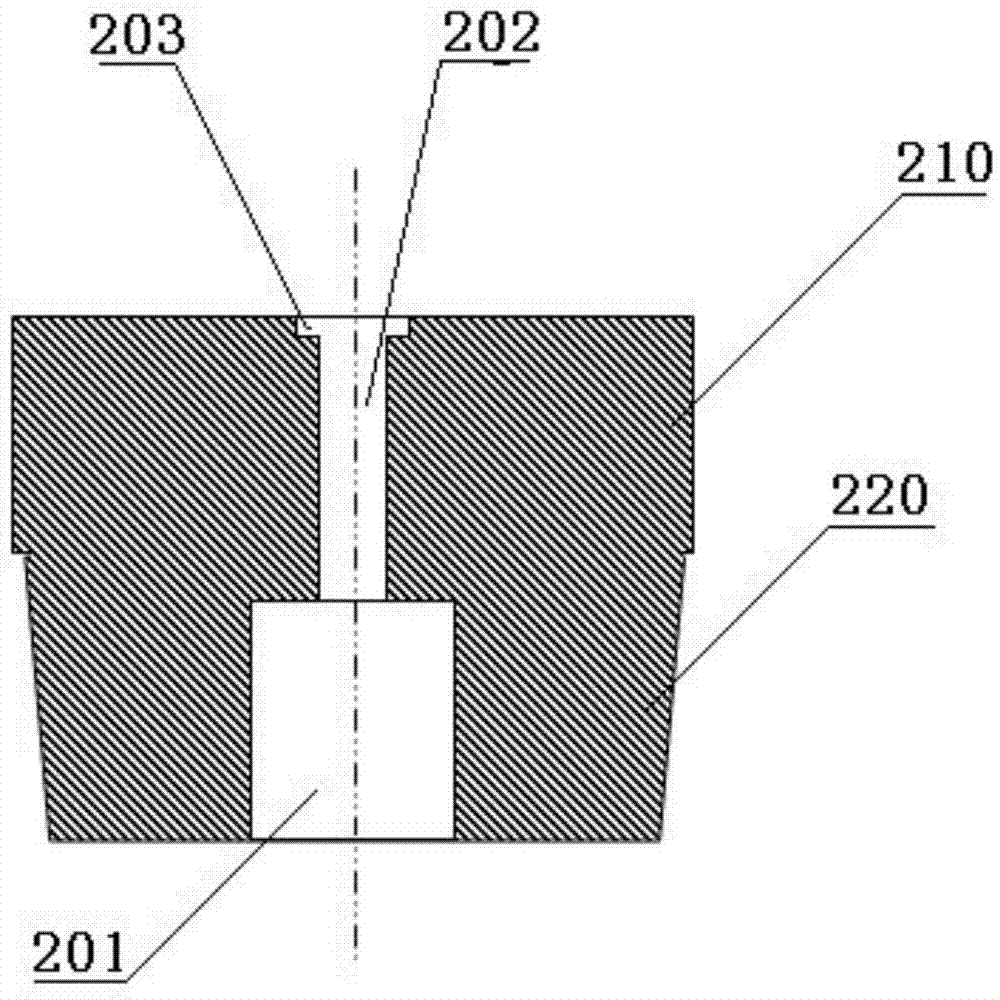

[0009] Referring to the accompanying drawings, which reflect a specific structure of the present invention, the combined fireworks outer cylinder is composed of a cylinder body 1 and a bottom plug 2 fixed at the bottom of the cylinder body 1, and the center position of the upper part of the bottom plug 2 is provided with a launcher. Drug chamber 201, the center of the firing chamber 201 is provided with an overfire hole 202 that runs through the lower part of the bottom plug 2, and the upper port of the fire through hole 202 passes through the firing chamber 201; the bottom end surface of the bottom plug 2 is provided with a lead wire that traverses the bottom end surface The installation groove 203 and the lower port of the fire through hole 202 pass through the lead wire installation groove 203; the bottom plug 2 is composed of a cylindrical seat body 210 and a frustum-shaped insert body 220. Sealing gunpowder is installed in the through-hole 202, and the sealing powder is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com