Temperature sensor based on hollow annular waveguide optical fiber

A technology of temperature sensor and ring waveguide, which is applied in the coupling of optical waveguide, thermometers with physical/chemical changes, thermometers, etc., can solve the problems of increasing structural instability, high reflectivity requirements, and low sensitivity of temperature sensors. Achieve the effect of realizing quasi-distribution measurement and improving temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with examples in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited by this.

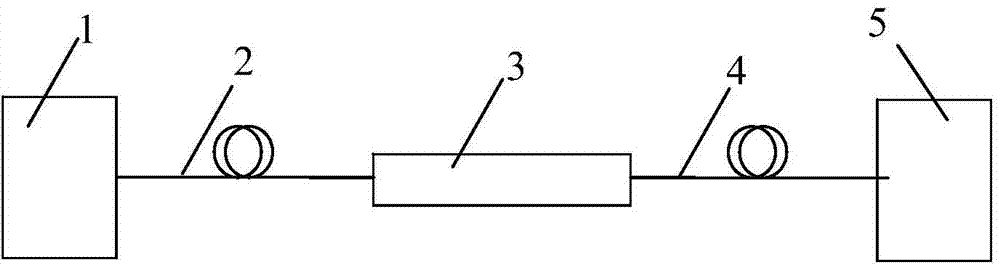

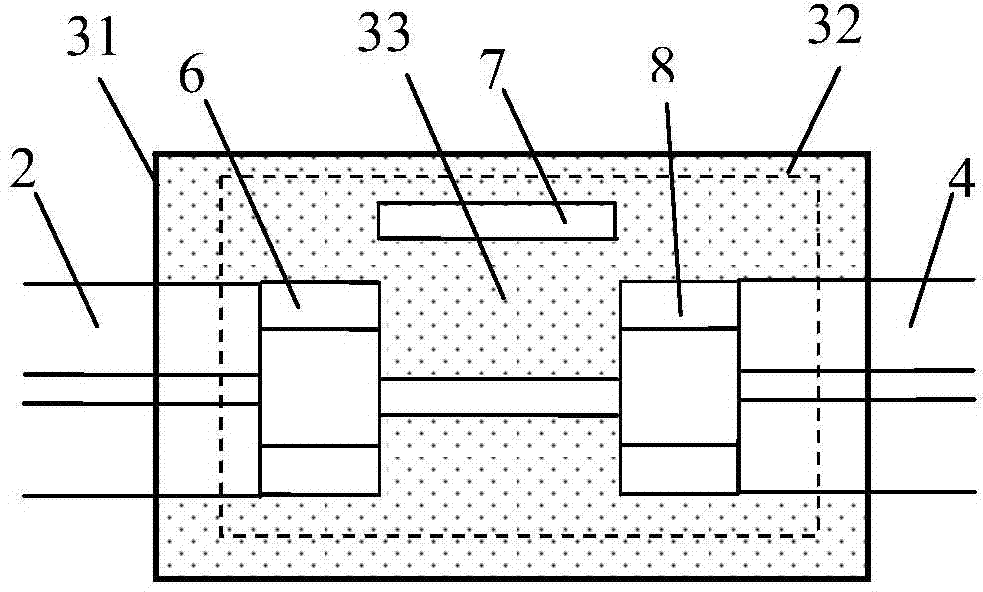

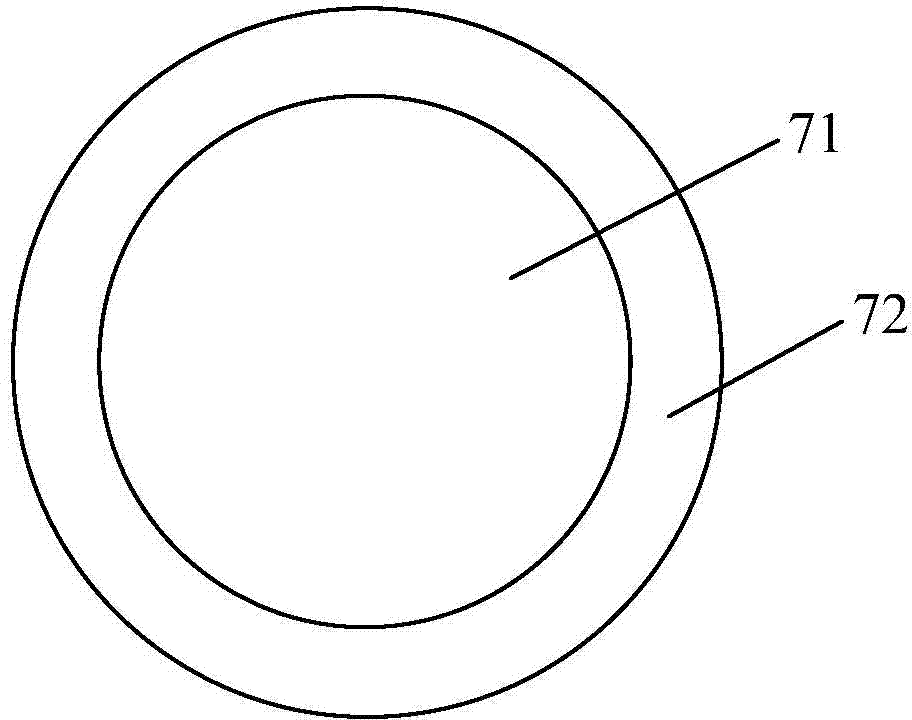

[0018] combine figure 1 and figure 2 , a kind of temperature sensor based on hollow ring waveguide fiber of the present invention, comprises broadband light source 1, input single-mode optical fiber 2, optical fiber sensing head 3, output single-mode optical fiber 4 and spectrum analyzer 5; Optical fiber sensing head 3 One end is connected to the light source 1 through the input single-mode optical fiber 2, and the other end is connected to the spectrum analyzer 5 through the output single-mode optical fiber 4; the optical fiber sensing head 3 is composed of a capillary 31, an optical fiber Mach-Zehnder interferometer 32 packaged in the capillary and Composed of high thermo-optic coefficient liquid 33; optical fiber Mach-Zehnder interferometer 32 is composed of input single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com