Simulating experiment method of rock natural seepage ability

A technique for simulating experiments and seepage, applied in permeability/surface area analysis, measuring devices, suspension and porous material analysis, etc., can solve problems that are difficult to directly and accurately reflect the actual seepage capacity of rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

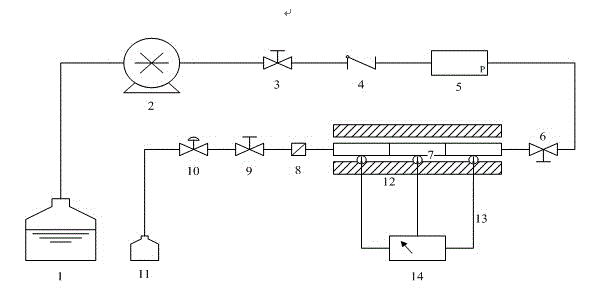

Method used

Image

Examples

Embodiment 1

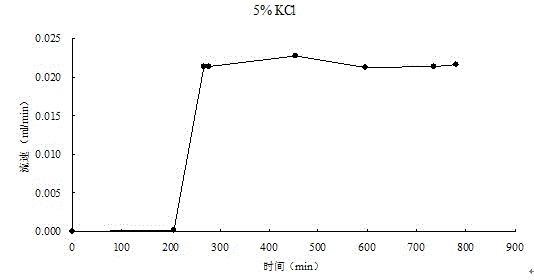

[0026] The experimental sample is a 3293.37m core column sample from Well 1, with a length of 1.2cm and a diameter of 2cm. The rock type is shale-bearing dolomitic fine-grained lithic arkose sandstone. Porosity 13%, permeability 0.76×10 -3 μm 2 . The fluid pressure of the coring section is 31.64 MPa. The formation temperature is 130°C.

[0027] Experimental conditions: the solution is KCl solution, the concentration is 5000mg / L; the experimental pressure is 10MPa. The flow rate of the injection pump in the reactor is 1.5ml / min, and the flow rate of the injection pump at the confining pressure of the reactor is 2ml / min.

[0028] Experimental temperature control: Under the condition of 20°C in the room, start timing at the outlet of the displacement fluid, after 2 hours of displacement. The electronically controlled temperature was raised to 130°C, and the displacement was stabilized for 1 hour. The temperature is electronically controlled to 210°C, and the displacement ...

Embodiment 2

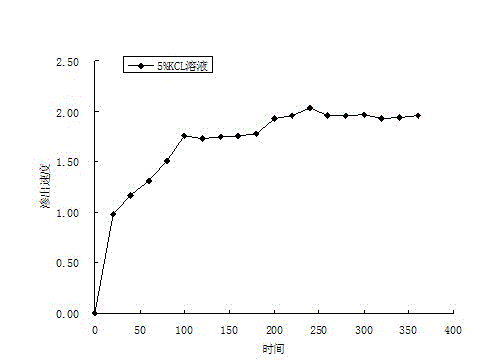

[0038] The experimental sample is a 3293.37m core column sample from Well 1, with a length of 4.8cm and a diameter of 2.45cm. The rock type is shale-bearing dolomitic fine-grained lithic arkose sandstone. Porosity 13%, permeability 0.76×10 -3 μm 2 . The fluid pressure of the coring section is 31.64 MPa. The formation temperature is 130°C.

[0039] Experimental conditions: the solution is KCl solution, the concentration is 5000mg / L; the experimental pressure is 30MPa. The flow rate of the injection pump in the reactor is 1.5ml / min, and the flow rate of the injection pump at the confining pressure of the reactor is 2ml / min.

[0040] Experimental temperature control: Under the condition of 20°C in the room, start timing at the outlet of the displacement fluid, after 2 hours of displacement. The electronically controlled temperature was raised to 130°C, and the displacement was stabilized for 1 hour. The temperature is electronically controlled to 210°C, and the displaceme...

Embodiment 3

[0054] The experimental sample was selected from Well Xia 503 in Huimin Sag with a length of 3387.5m and a core length of 3.61cm and a diameter of 2.48cm. The rock type is very fine-grained arkose. Porosity 13%, permeability 2.12×10 -3 μm 2 . The fluid pressure of the coring section is 41.50MPa. The formation temperature is 133°C.

[0055] Experimental conditions: the solution is KCl solution with a concentration of 5000mg / L; the experimental temperature of formation conditions is 133°C; the experimental pressure is 40MPa. The flow rate of the injection pump in the reactor is 2.5ml / min, and the flow rate of the injection pump at the confining pressure of the reactor is 2ml / min.

[0056] Experimental temperature control: Under the condition of 20°C in the room, start timing at the outlet of the displacement fluid, after 2 hours of displacement. The electronically controlled temperature was raised to 130°C, and the displacement was stabilized for 3 hours. The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com