Anisotropy film heat conductivity testing method and device based on heat flux sensors

A heat flow sensor and testing device technology, applied in the direction of material thermal development, etc., can solve problems such as complex operation, complex system, and complexity, and achieve the effects of easy and reliable operation, simple device structure, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

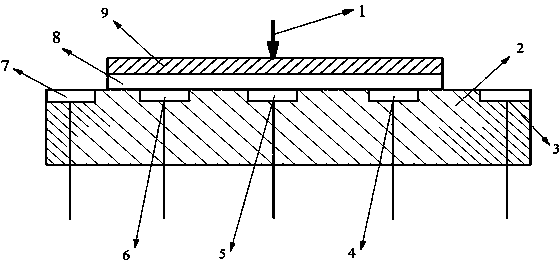

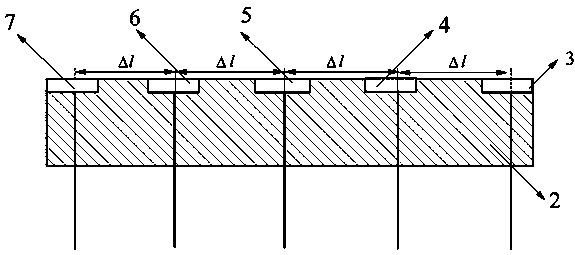

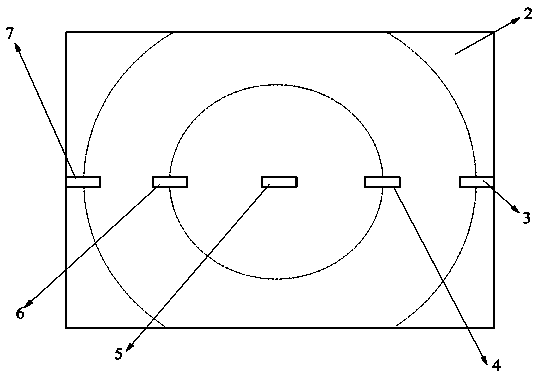

[0018] see figure 1 , an anisotropic film thermal conductivity test device based on a heat flow sensor of the present invention includes a heating head 1, a test platform 2 and a plurality of heat flow sensors (HFS, Heat Flux Sensor), figure 1 Shown in the figure are five heat flow sensors 3, 4, 5, 6, 7, a plurality of heat flow sensors are embedded in the test platform 2, and each heat flow sensor is drawn from the bottom of the test platform 2 through its own lead line, The lead-out line is in the form of a USB port. The sample substrate 8 to be tested is placed on the upper surface of the test platform 2 , and the sample of the thin film 9 to be tested is placed on the upper surface of the test sample substrate 8 . The heating head 1 is located on the surface of the film 9 to be tested, and is heated on the surface. The heating head 1 adopts an electric heating method, which is realized by using a thermistor.

[0019] For the embedding method of the five heat flow sensors...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com