Automatic calculation method and module of support hanger in three-dimensional process plant design

A factory design and hanger technology, applied in the computer field, can solve the problems of complex three-dimensional space positioning, low design efficiency, high error rate, etc., achieve high precision, fast speed, and reduce design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

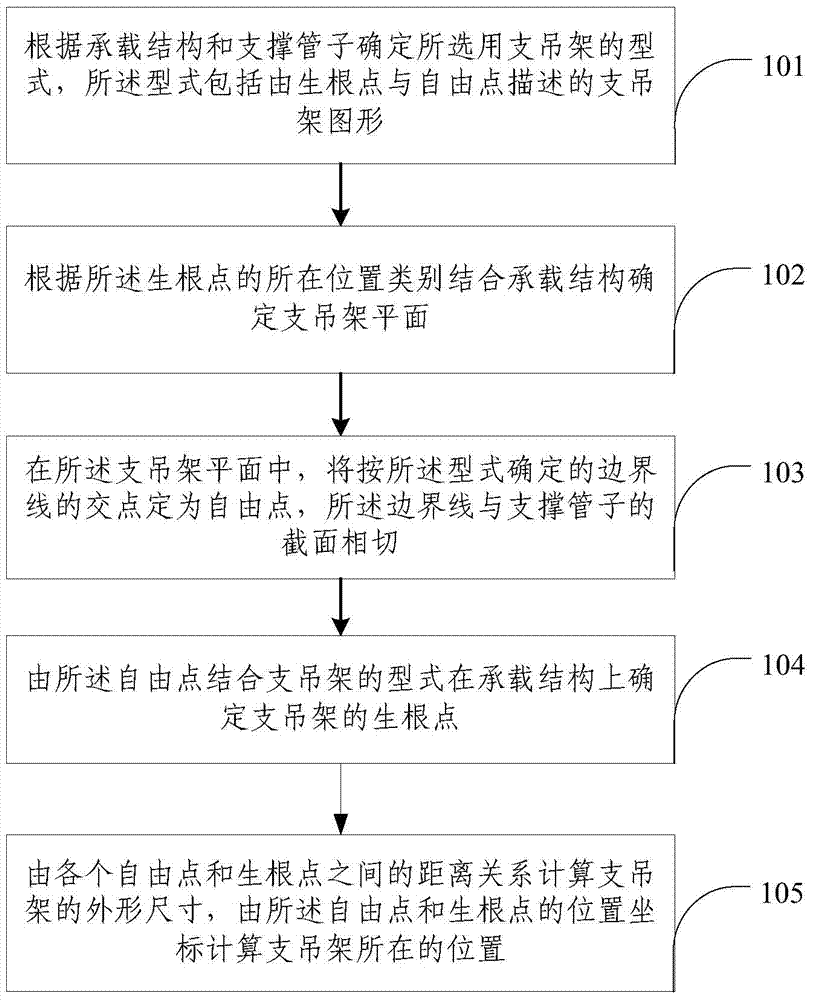

[0040] The embodiment of the present invention proposes an automatic calculation method for supports and hangers in three-dimensional process factory design, see figure 1 , the method includes:

[0041] Step 101: Determine the type of load-bearing structure, supporting pipes and selected supports and hangers;

[0042] Step 102: Calculate the plane of the support and hanger according to the load-bearing structure and the form of the selected support and hanger;

[0043] Step 103: In the plane of the support and hanger, set the intersection point of the boundary line determined according to the type as a free point, and the boundary line is tangent to the section of the supporting pipe;

[0044] Step 104: Determine the rooting point of the support and hanger on the load-bearing structure according to the position of the free point and the type of the support and hanger;

[0045] Step 105: Calculate the external dimensions of the support and hanger from the distance relationshi...

Embodiment 2

[0073] The embodiment of the present invention proposes an automatic calculation module for supports and hangers in three-dimensional process factory design, see Figure 8 , the module includes:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com