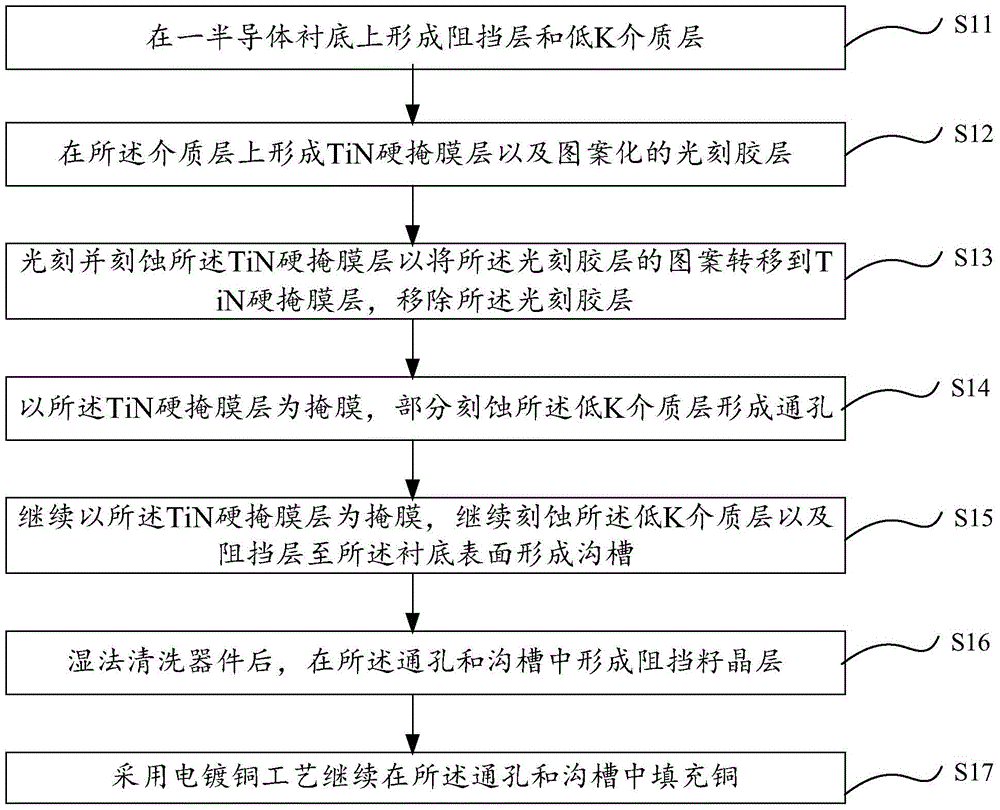

Metal hard mask structure, manufacturing method and copper interconnection structure manufacturing method

A technology of copper interconnection structure and metal hard mask, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of copper interconnection structure failure, performance degradation, peeling, etc., to reduce filling defects and improve Morphology, the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose and features of the present invention more obvious and easy to understand, the following will further describe the specific embodiments of the present invention in conjunction with the accompanying drawings. However, the present invention can be realized in different forms, and should not be considered as being limited to the described embodiments .

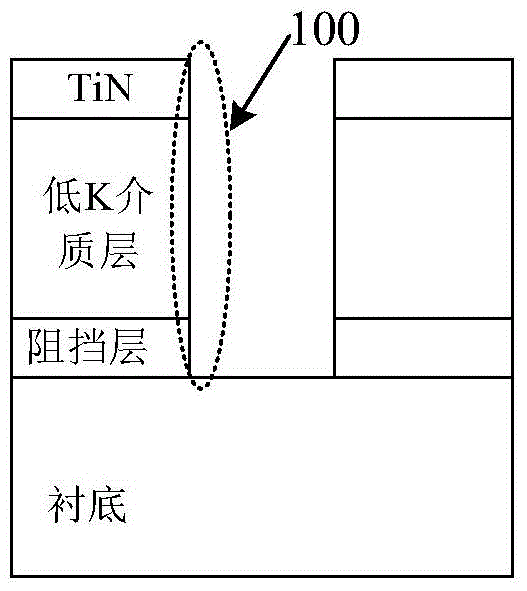

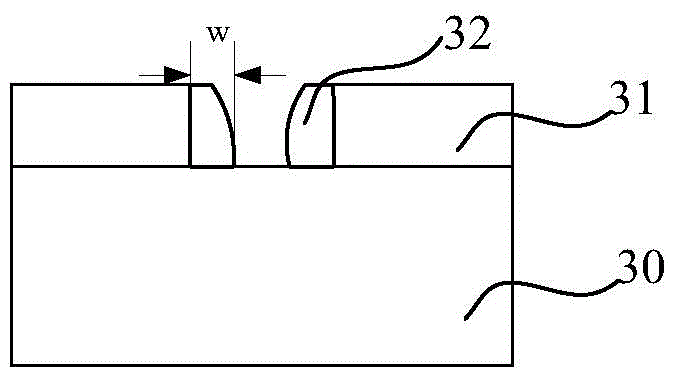

[0043] Please refer to image 3 , the present invention proposes a metal hard mask structure, including: a patterned metal hard mask layer 31 located on a substrate 30 and inner wall metal hard mask layers formed on both inner sidewalls of the patterned metal hard mask layer 31 A mask layer 32 (spacer), the etching selectivity ratio of the inner wall metal hard mask layer 32 and the patterned metal hard mask layer 31 is different.

[0044] Wherein, the patterned metal mask layer 31 can be titanium nitride TiN (MHM), utilizing the high etching property between TiN and the low-K dielectric layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com