Valve-regulated lead acid battery inner formation technology capable of controlling battery separator saturation

A technology for controlling separators and batteries, which is applied in the direction of lead-acid batteries, lead-acid battery construction, secondary batteries, etc., and can solve problems such as inability to effectively control the saturation of separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

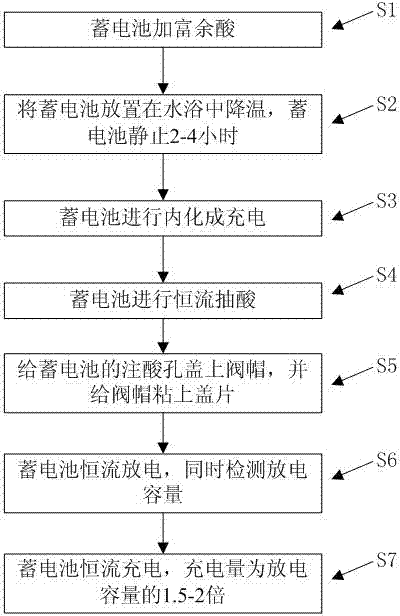

[0023] Embodiment: A valve-controlled sealed battery internalization process for controlling the saturation of the separator in this embodiment, the battery is a 6-DZM-12 battery, such as figure 1 shown, including the following steps:

[0024] S1: add surplus acid to the battery;

[0025] S2: Place the battery in a water bath at 20°C to cool down, and let the battery rest for 3 hours;

[0026] S3: The battery is internalized and charged (internalized and charged using the existing mature technology);

[0027] S4: 2 hours before the end of formation charging, use the constant current of 1.2A at the end of the formation to pump acid. After 0.5 hours of acid pumping, check whether there is free acid in the upper part of the battery pole group. If there is free acid, take it out and check again , and work in this cycle until there is no free acid in the upper part of the battery pole group;

[0028] S5: Cover the acid injection hole of the battery with a valve cap, and stick a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com