Air discharge pipe structure for melting snow on road surface, road surface material for melting snow, and system for melting snow on road surface

A technology for exhaust pipes and structures, applied in the directions of roads, roads, pavement details, etc., can solve the problems of difficult construction, uneven snow melting, and no special consideration of uneven snow melting, so as to reduce construction time and construction costs, and facilitate construction. The effect of suppressing uneven snow melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

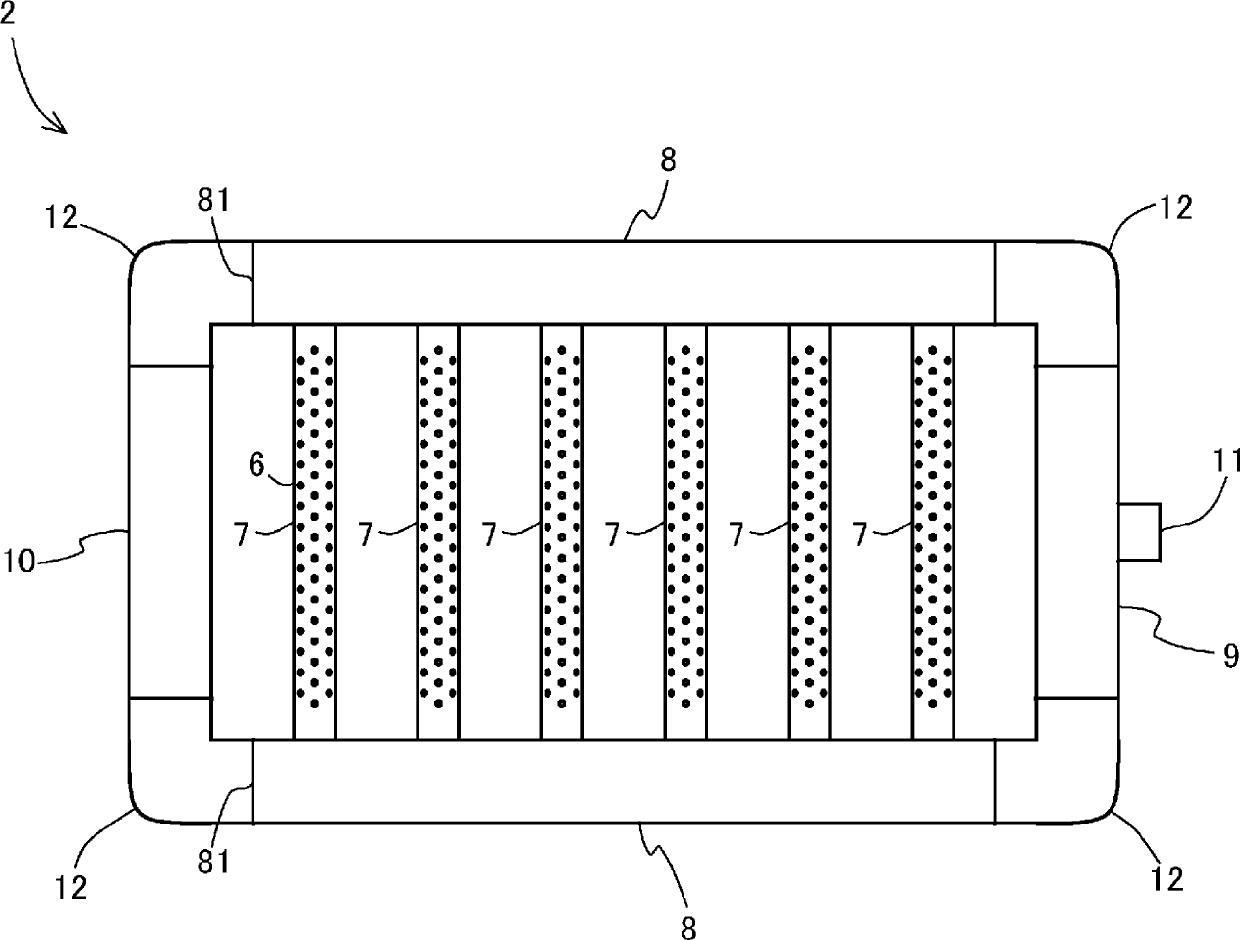

[0085] Next, an experiment was conducted to investigate the practicality of the function and effect of the exhaust pipe structure 2 for road surface snow melting according to the present invention. In Example 1, the fluid when the plurality of perforated pipes 7, 7 ... of the road surface snow-melting exhaust pipe structure 2 are surrounded in a substantially U-shape or substantially annular to allow ventilation is performed using a fluid analysis program. analyze. The thermal fluid analysis programs used in Example 1 are commercially available SolidWorks and COSMOSFloWorks.

[0086] Figure 8 as well as Figure 9 The analysis model used in the simulation of this Example 1 is shown. These models were modeled using SolidWorks. Figure 8 In the model shown as a comparative example, only one end of a plurality of perforated tubes 7, 7... is connected by a connecting tube 8 for ventilation, and the other end is closed. In addition, one end of the connecting pipe 8 for ventila...

Embodiment 2

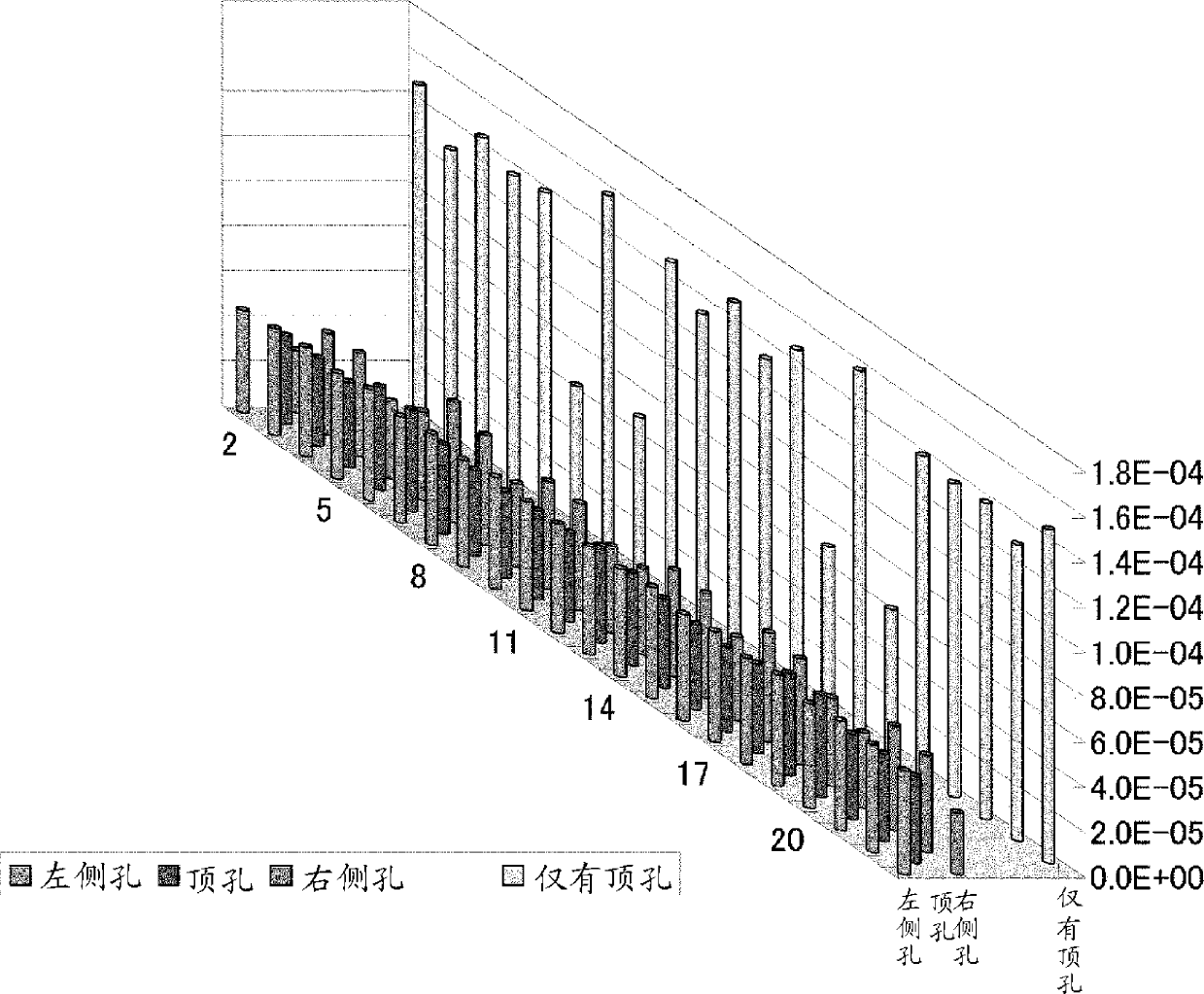

[0106] In Example 2, the number of air ejection holes 6 formed in the perforated tube 7 and the amount of air ejection were simulated using a fluid analysis program. The thermal fluid analysis program used is the same SolidWorks and COSMOSFloWorks as in Example 1.

[0107] Figure 16 as well as Figure 17 The analysis model used in the simulation of this Example 2 is shown. Figure 16 In the model shown, the air ejection hole 6 in the exhaust pipe structure 2 for melting snow on the road surface is constituted only by the top hole 61 . on the other hand, Figure 17In the model shown, the air ejection hole 6 in the exhaust pipe structure 2 for road surface snow melting is composed of a top hole 61 , a right hole 62 , and a left hole 63 .

[0108] Conditions common to each model will be described. First, the length of the perforated pipe 7 is 2300mm. The number of perforated tubes 7 is two, and they are arranged in parallel at intervals of 300 mm. In addition, the marks A...

Embodiment 3

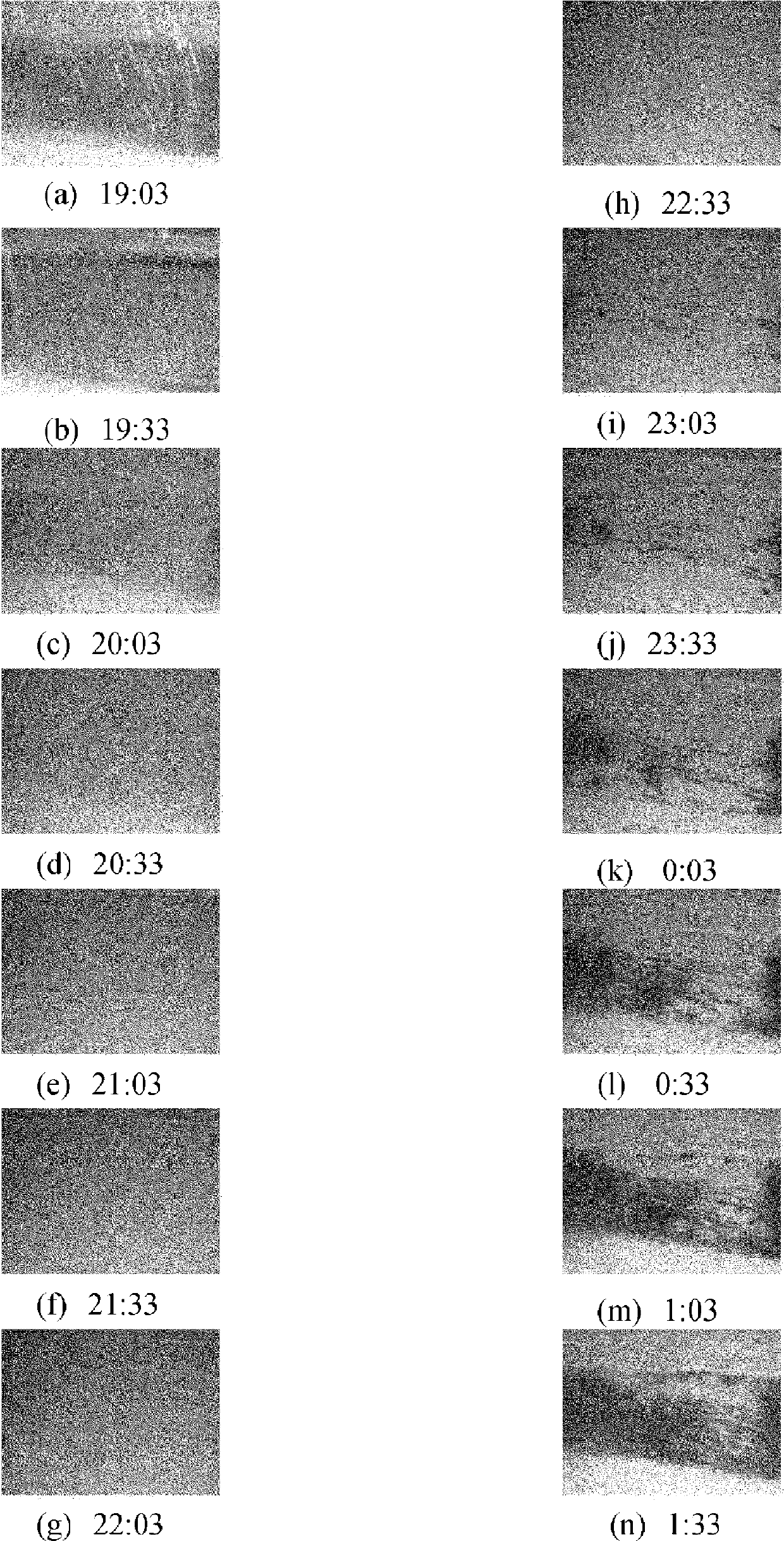

[0119] In Example 3, made Figure 20 The shown road surface snow melting system 1 using the road surface snow melting exhaust pipe structure 2 of the present invention was actually buried under the road surface 5 to conduct a demonstration experiment of the snow melting effect of the road surface snow melting system 1 .

[0120] The exhaust pipe structure 2 for road surface snow melting in the present embodiment 3 is as follows: Figure 21 As shown, a plurality of perforated tubes 7, 7... are surrounded by an air supply tube 9, a pair of connecting tubes 8, 8 for ventilation, and an end ventilation tube 10 in a substantially annular shape so that ventilation is possible. And the range which is the target of snow melting is divided into four blocks, and the exhaust pipe structure 2 for road surface snow melting of a substantially ring shape is arrange|positioned for each block.

[0121] The perforated tube 7 in Example 3 is formed of a polyvinyl chloride tube with an inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com