Automatic betel nut seed sorting device

An automatic sorting and sorting technology, applied in sorting and other directions, can solve the problems of insufficient sorting efficiency and sorting accuracy of the sorting mechanism, difficult to adapt to betel nut sorting occasions, and low stability, etc. The effect of low cost and improved sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

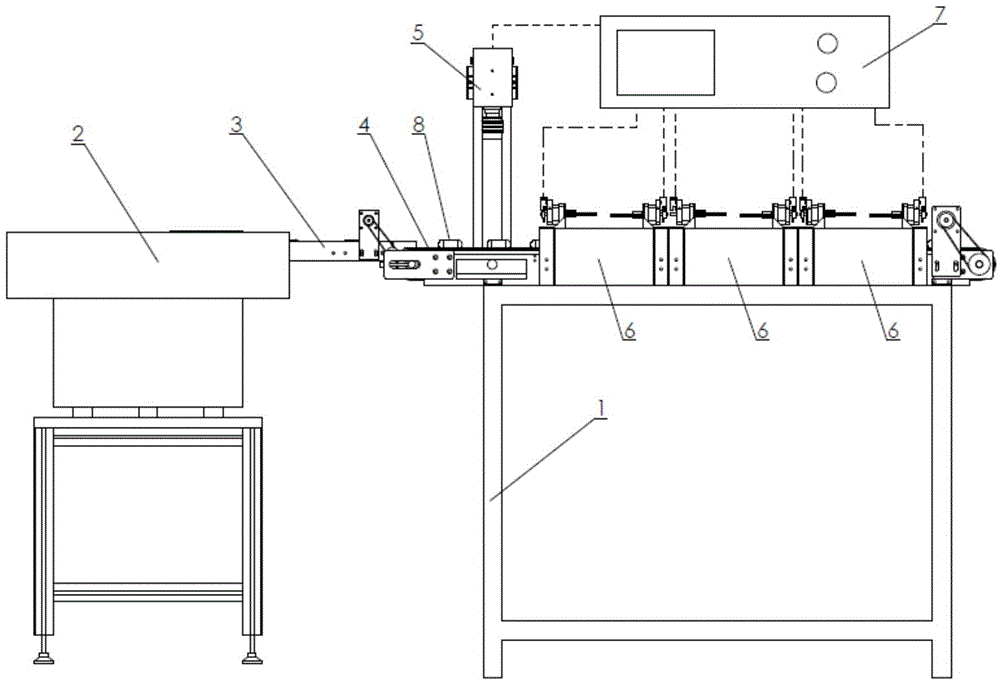

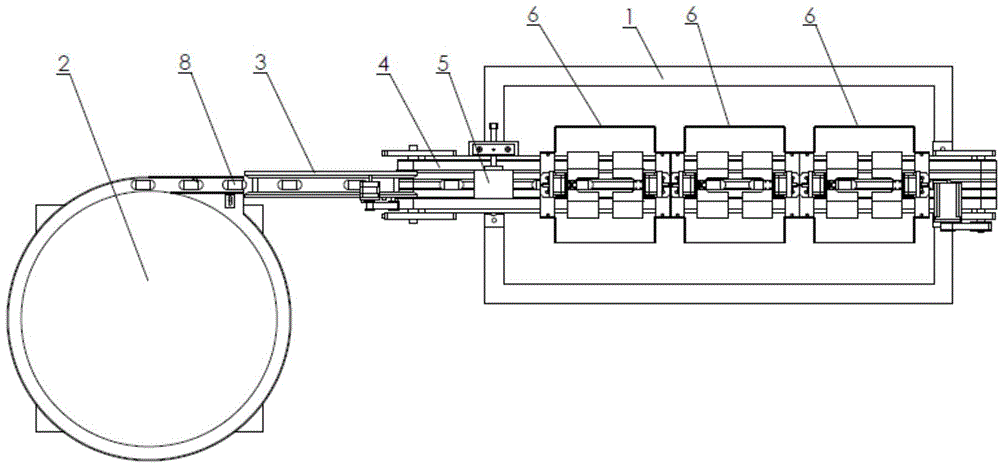

[0041] Such as figure 1 , 2 As shown, this embodiment includes a frame assembly 1, a vibrating plate feeding assembly 2 installed on the frame assembly and connected in sequence, a connecting conveyor belt assembly 3, a main conveyor belt assembly 4, a visual inspection assembly 5, a sorting execution assembly 6 and a control System 7.

[0042] (1) The vibrating plate feeding assembly is mainly composed of a vibrating plate and a vibrating plate supporting frame. The vibrating plate is fixed on the vibrating plate supporting frame. Its function is to use the principle of centrifugal vibration to arrange the scattered piles of betel nut seeds in the vibrating plate into end to end connection. single row, and sent to the connecting conveyor belt assembly. The vibrating plate is currently used as a feeding device widely used in industry, and it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com