Copper foil cleaning machine based on sidesway

A washing machine and copper foil technology, applied in the direction of cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems affecting product quality, etc., and achieve simple structure, water saving, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

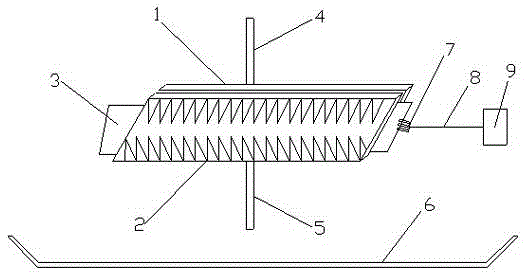

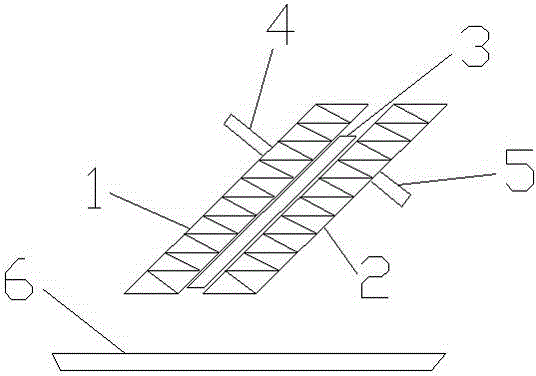

[0016] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0017] Such as figure 1 and figure 2 As shown, a copper foil cleaning machine based on side shifting includes an upper felt piece 1 and a lower felt piece 2 with equal lengths and superimposed on each other. Aligned with the horizontal plane, extending upward in the width direction and inclined to the horizontal plane, the copper foil moves along the length direction of both; the upper water injection pipe 4 is connected to the upper felt piece 1, and the lower water injection pipe 5 is connected to the lower felt piece 2 ; A sewage collection tank 6 is also provided below the lower felt piece 2; it also includes a pulling mechanism composed of sequentially connected "E"-shaped clamping parts 7, pull wires 8, and wire take-up assemblies 9, which are used to pull the copper foil 3 to generate sideways.

[0018] The innovation point of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com