Three-dimensional printer

A technology of a three-dimensional printer and a print head, applied in the field of three-dimensional printers, can solve the problems of reducing response sensitivity, increasing control complexity, and inability to perform fast printing, etc., and achieves the effect of facilitating refueling, simplifying control and the structure of the refueling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

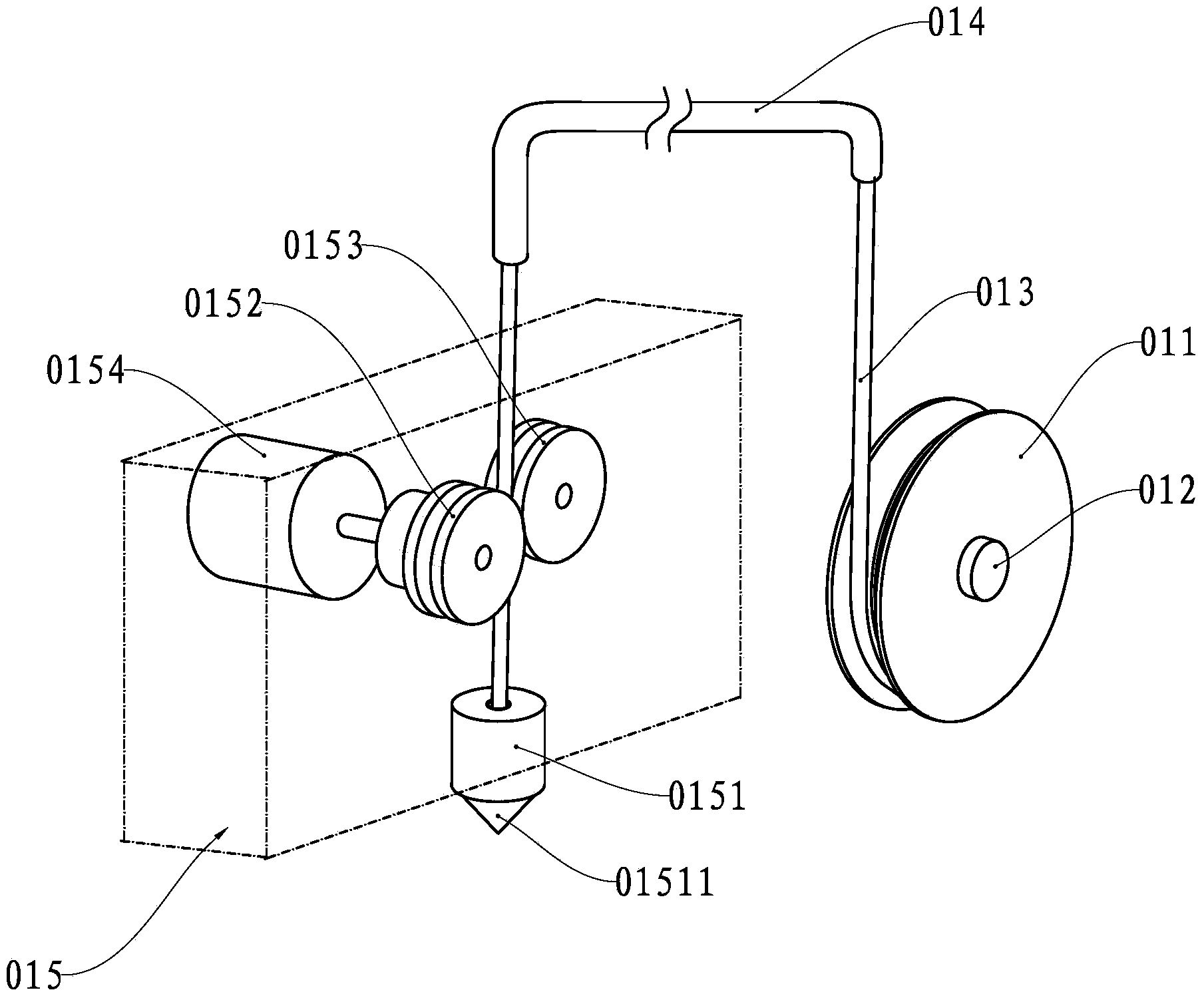

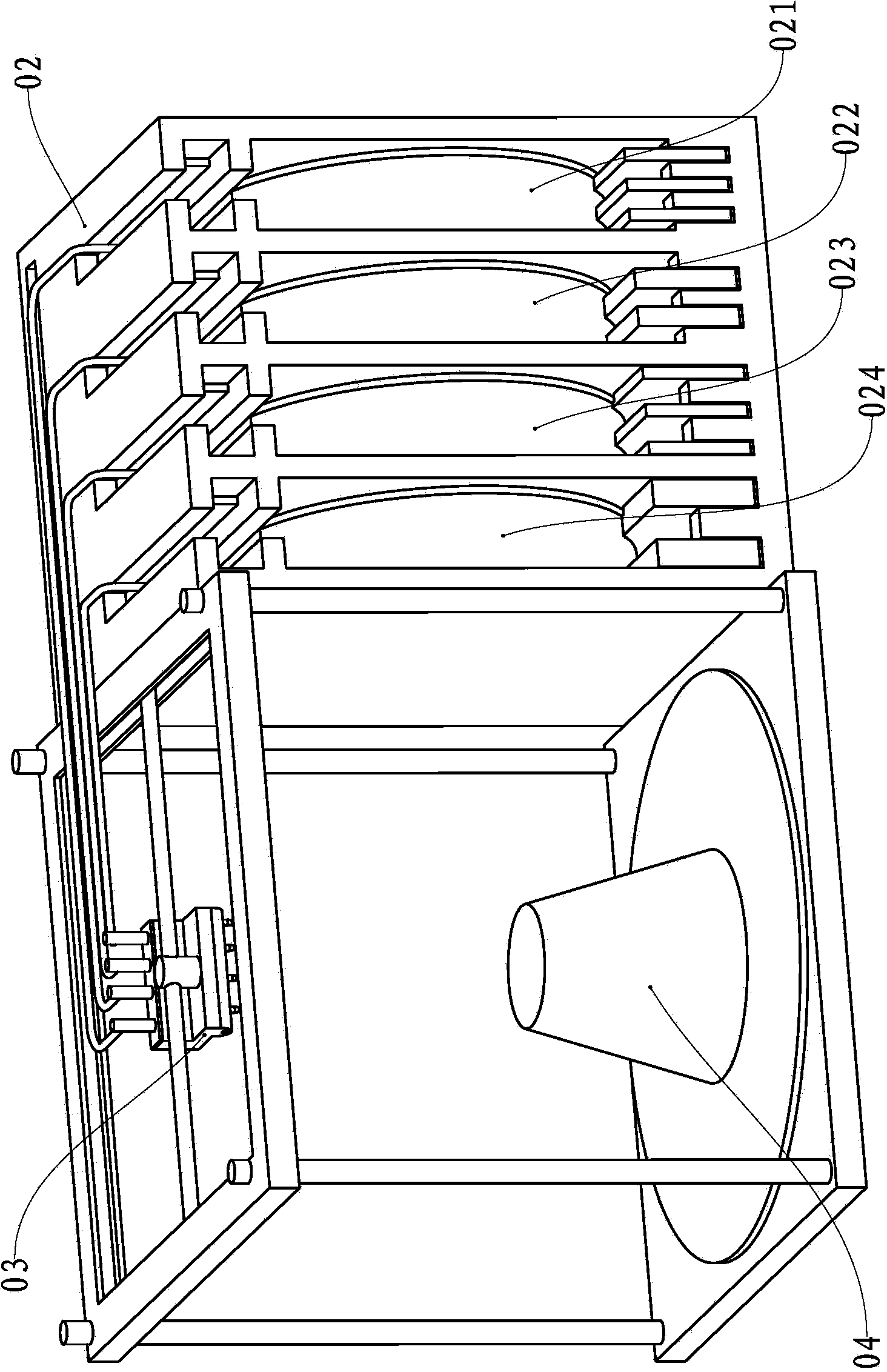

[0033] see Figure 4 , this example three-dimensional printer is made of feeding device 1, refueling device 2, printing head 3, stage 4, frame 5 and controller; The material box 12, the wire material box 13, the wire material box 14, the wire material box 15 and the wire material box 16 are composed; the controller controls the movement of the printing head 3 in the horizontal X-Y plane, and simultaneously controls the stage 4 and the material changer 2 Move in the vertical Z direction; the feeder 2 is a disc body, and the first feeding unit 21, the second feeding unit 22, the third feeding unit 23, and the fourth feeding unit 24 are evenly distributed along the circumference of the feeder 2 , the fifth feeding unit 25 and the sixth feeding unit; the six silk boxes on the feeding device 1 supply monochrome silk to the six feeding units respectively.

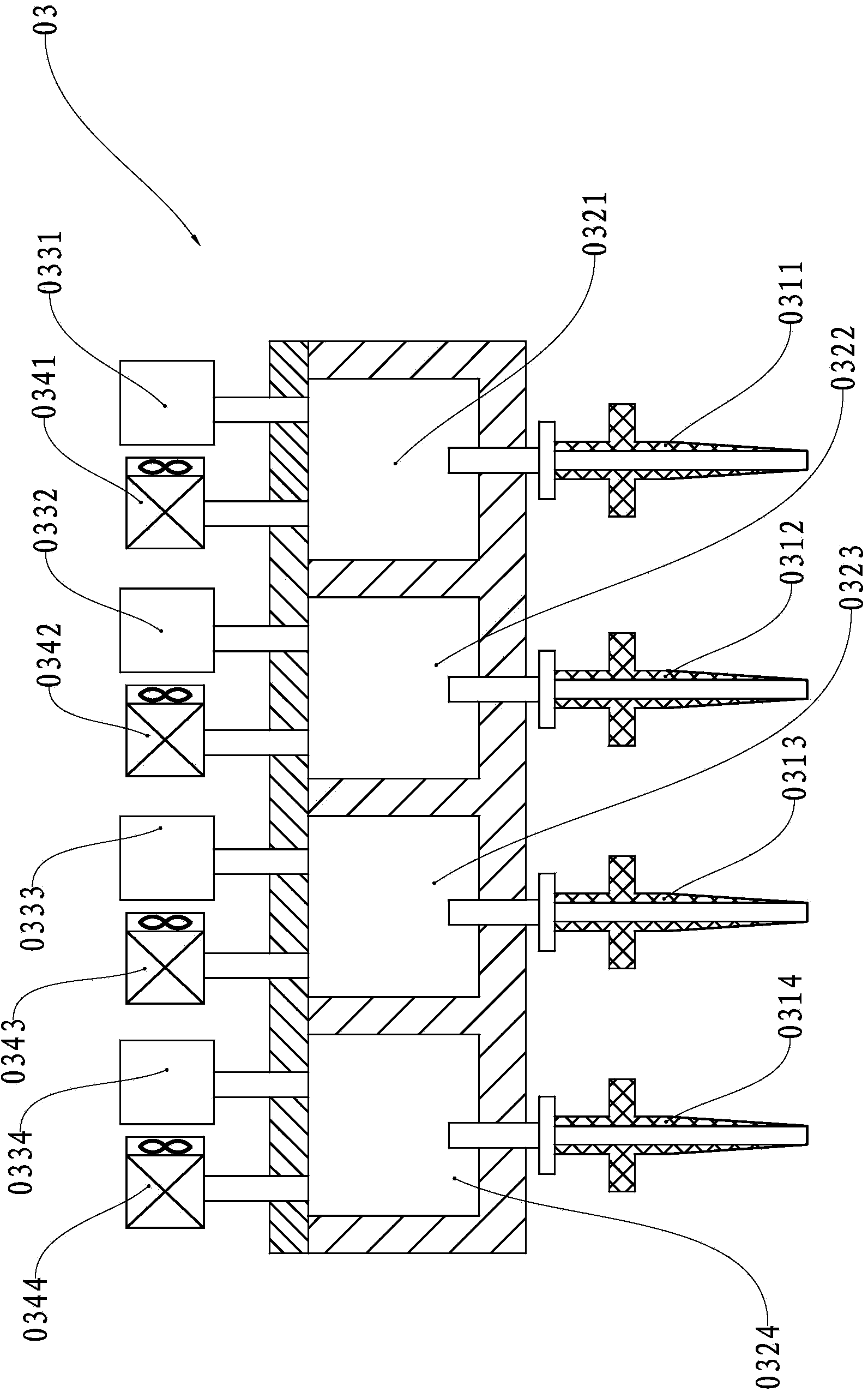

[0034] see Figure 5 , the first feeding unit 21 has a feeding wheel 211 and a feeding wheel 212, and the second feeding unit...

no. 2 example

[0046] As an explanation of the second embodiment of the present invention, only the differences from the above-mentioned first embodiment will be described below. The material changer is a rectangular plate structure, and 6 feeding units are installed on the rectangular plate in a line or array.

no. 3 example

[0048] As a description of the third embodiment of the present invention, only the differences from the above-mentioned first embodiment will be described below. The stage and the material changer are fixed relative to the frame, and the print head moves in the X-Y-Z three-dimensional space under the control of the controller; during the material change process, the relative movement between the material changer and the print head is controlled by the controller The print head is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com