Method of preparing potassium titanyl phosphate film by utilizing ion injection

A technology of potassium titanyl phosphate and ion implantation, applied in the field of nonlinear optical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

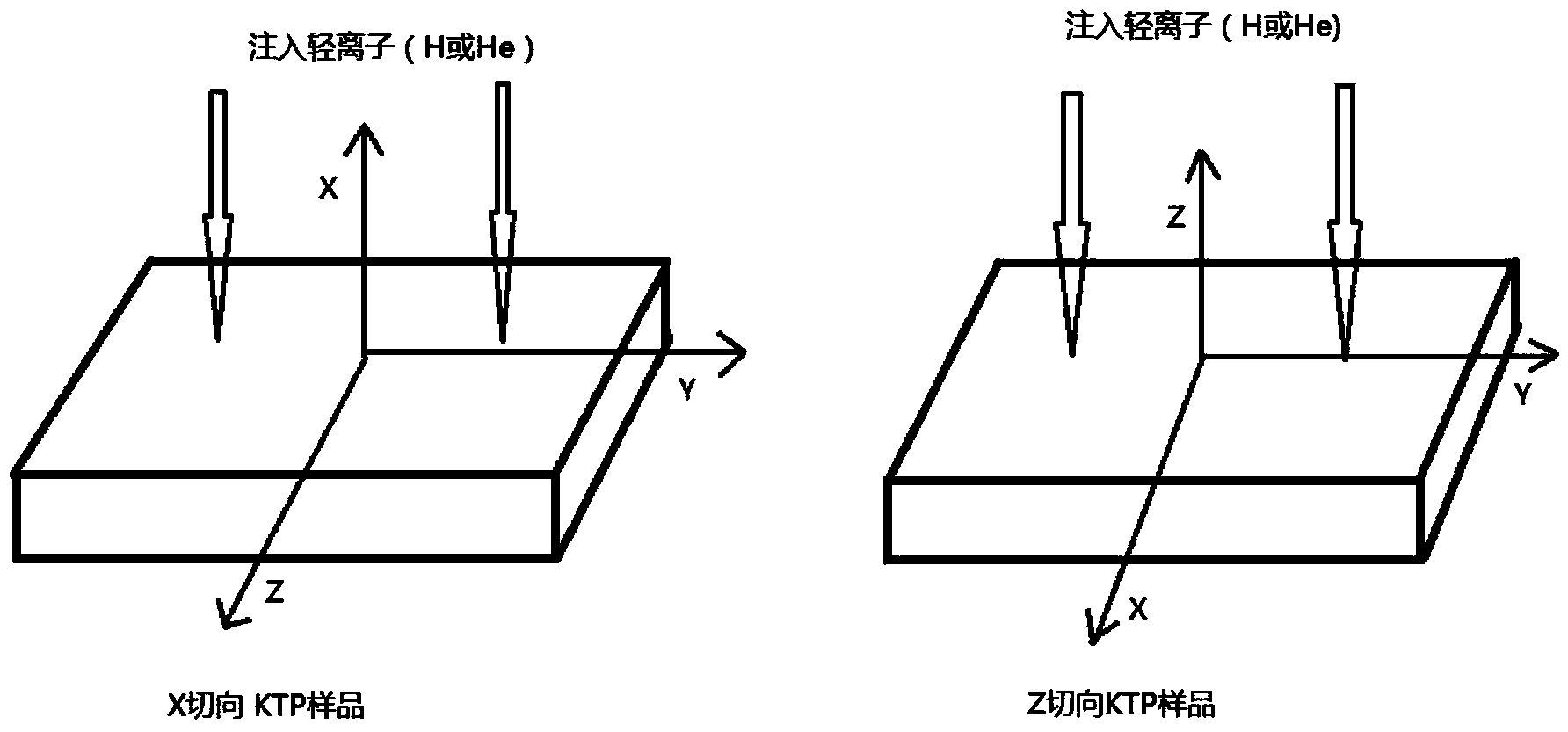

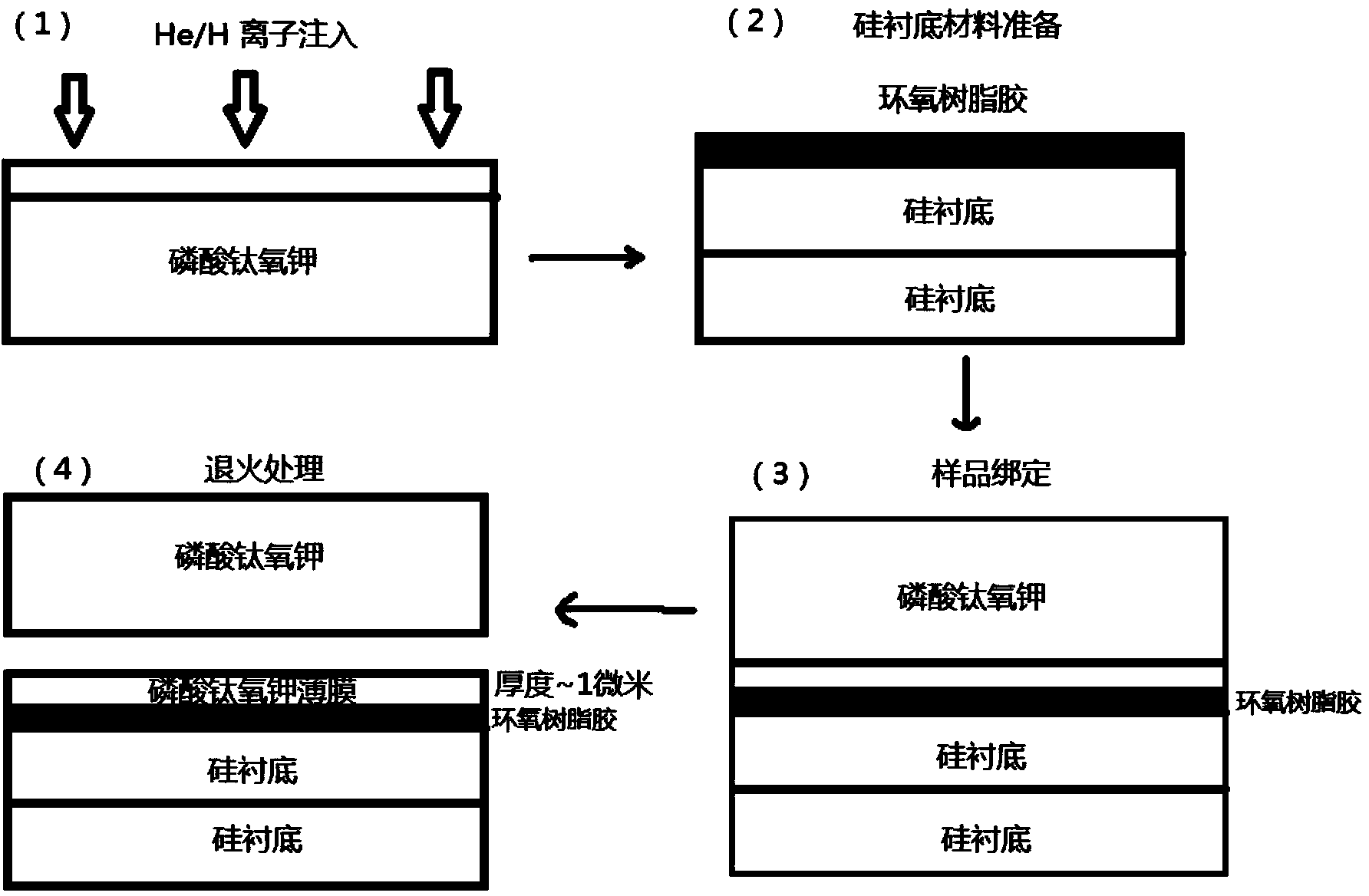

Method used

Image

Examples

Embodiment 1

[0024] H ions with an energy of 117keV are implanted into the X-tangential potassium titanyl phosphate material at room temperature, and the implantation dose range: 5×10 16 Ions / cm2~8×10 16 Ions / square centimeter; after implantation, the sample is bound to the silicon substrate with resin glue and annealed. The annealing temperature is gradually increased from room temperature to 200°C, and the total annealing time is 4 hours. The test results are as follows:

[0025] Sample serial number

Embodiment 2

[0027] H ions with an energy of 117keV are implanted into the Z-tangential potassium titanyl phosphate material at room temperature, and the implantation dose range: 5×10 16 Ions / cm2~8×10 16 Ions / square centimeter; after implantation, the sample is bound to the silicon substrate with resin glue and annealed. The annealing temperature is gradually increased from room temperature to 200°C, and the total annealing time is 2 hours. The test results are as follows:

[0028]

Embodiment 3

[0030] He ions with an energy of 200keV are implanted into the X and Z tangential potassium titanyl phosphate materials at room temperature, and the implantation dose range: 1×10 16 Ions / cm2~10×10 16 Ions / square centimeter; after implantation, the sample is bound to the silicon substrate with resin glue and annealed. The annealing temperature is gradually increased from room temperature to 600°C, and the total annealing time is 6 hours. The test results are as follows:

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com