Novel piece dyed mercerized knitted fabrics and manufacturing method thereof

A technology for knitted fabrics and production methods, applied in knitting, weft knitting, warp knitting, etc., which can solve the problems of long production time and high loss, and achieve the effects of reducing raw material costs, improving quality, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1. the novel mercerizing fabric of knitted piece dyeing kind

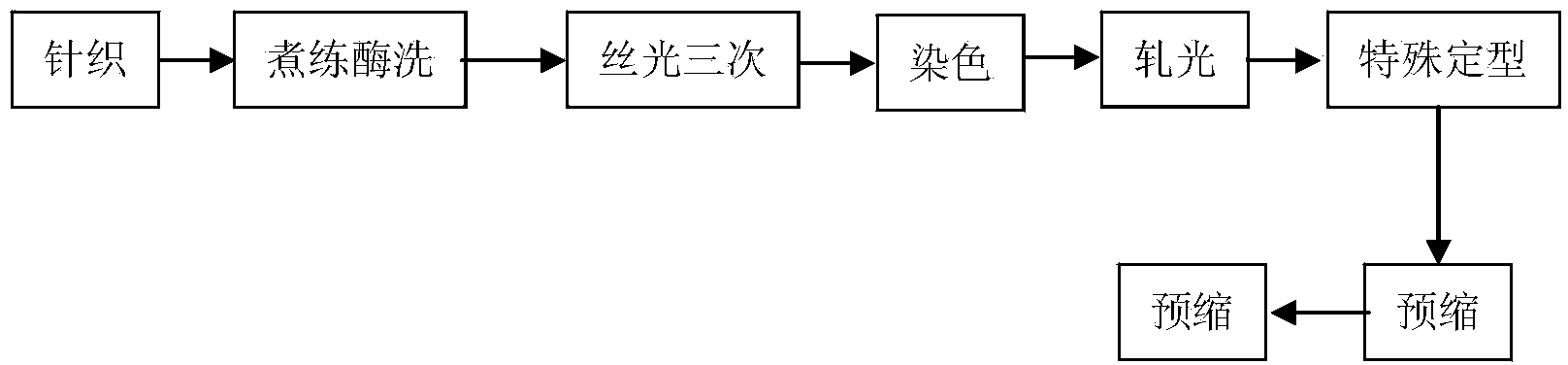

[0038] Take the production of finished product width 62inch, finished product gram weight 150GM, CPI=46, WPI=41.5 single-sided plain weave piece dyeing cotton knitting novel mercerized fabric as example below, the production method of this fabric comprises steps (see also figure 1 shown):

[0039] Gray yarn knitting: choose 137Compact yarn60S / 2 for knitting and weaving, specifically, the starting modulus is 96F, and the yarn length of 28G30” is 50C=132MM. MV4II single jersey machine is used to weave solid color plain pattern, and the reserve fabric is finished.

[0040] Scouring enzyme washing: the process is multi-functional bleaching pretreatment agent Clarite One1.5g / l, 50% caustic soda 2g / l, H 2 o 2 (27.5%) 3.6g / l, defoaming wetting accelerator ALBAFLOW JET0.3g / l, scouring at 95-100°C for 45-50min; Cellusoft L or Cellusoft combi, 1.5g / l, 50°C for 45min.

[0041] Open-width water rolling: Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com