Composite connection method for high-strength variable-diameter steel cable

A composite connection and high-strength technology, which is applied in the joints of textile materials, textile cables, auxiliary devices for rope making, etc. , Conducive to retracting and winding, avoiding the effect of process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] Taking the connection of Φ2.46mm (thick end) / Φ1.63mm (thin end) variable-diameter steel cable as an example, the structural parameters of the cable used for steel cable connection are shown in Table 1.

[0027] Table 1 selects the structural parameters of the cable

[0028]

[0029] The specific connection method is as follows:

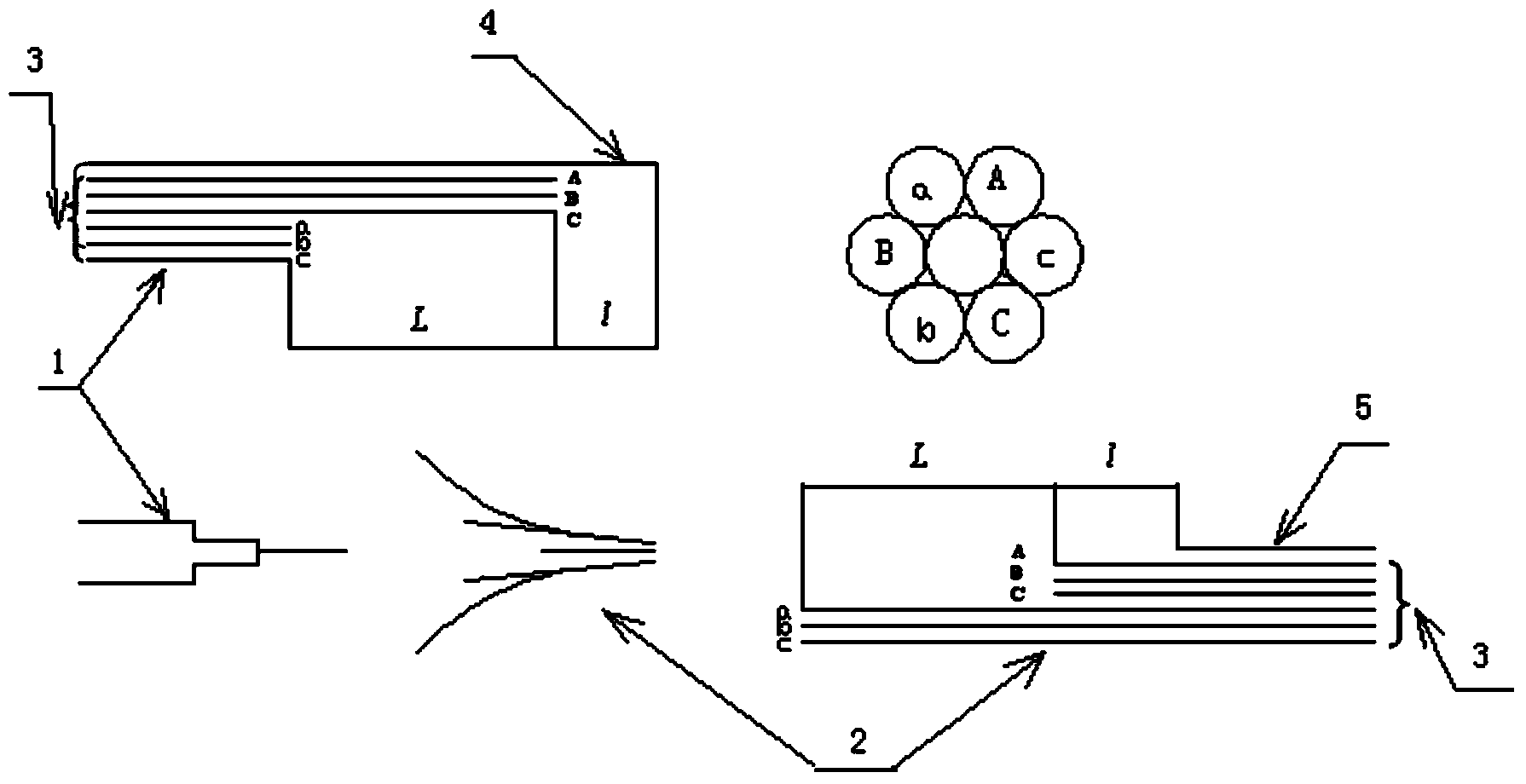

[0030] 1) if figure 1 As shown, the outer monofilament 3 in the connection area of the Φ2.46mm / Φ1.63mm variable-diameter steel cable is loosely twisted and opened, the central monofilament 4 of the Φ2.46 end steel cable is left long, and the center monofilament 4 of the Φ1.63 end steel cable 5 Cut short, the outer monofilaments in the joint area of the two steel cables are divided into 2 groups and cut short, deburring;

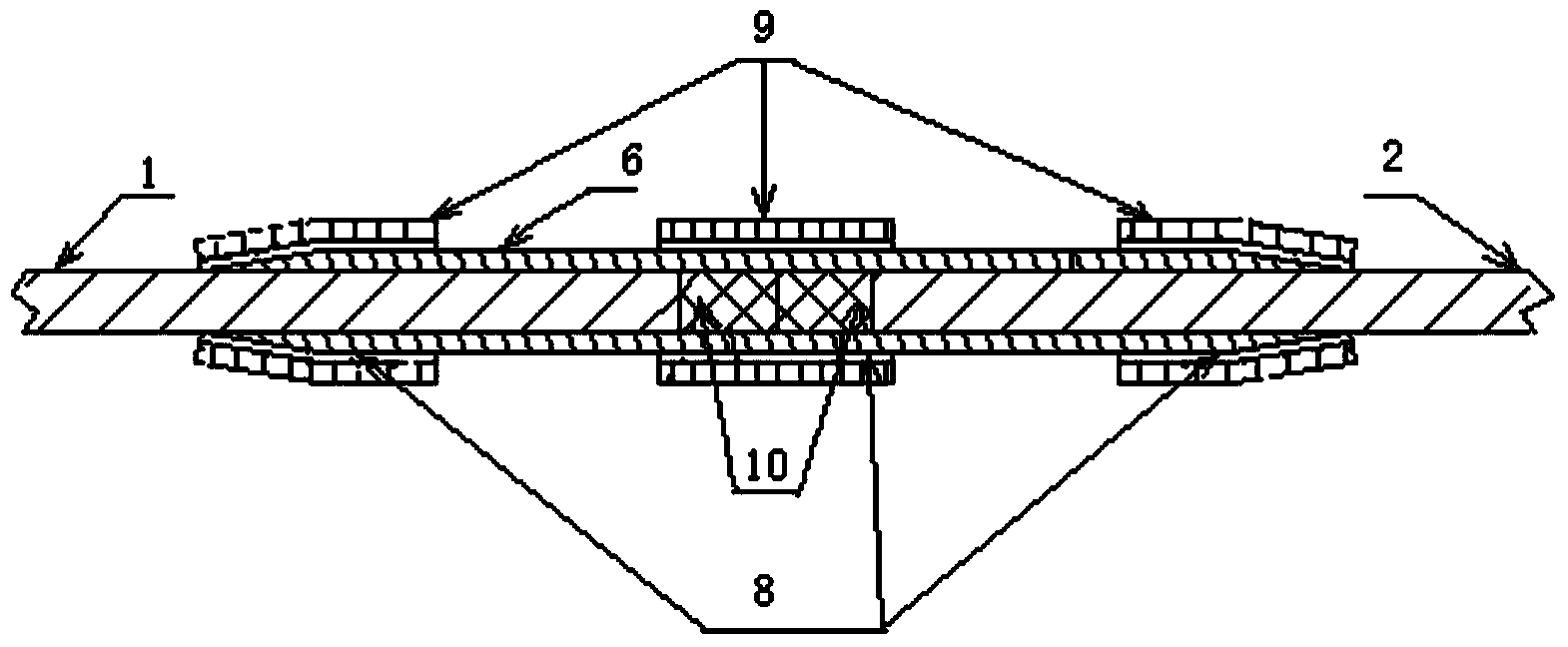

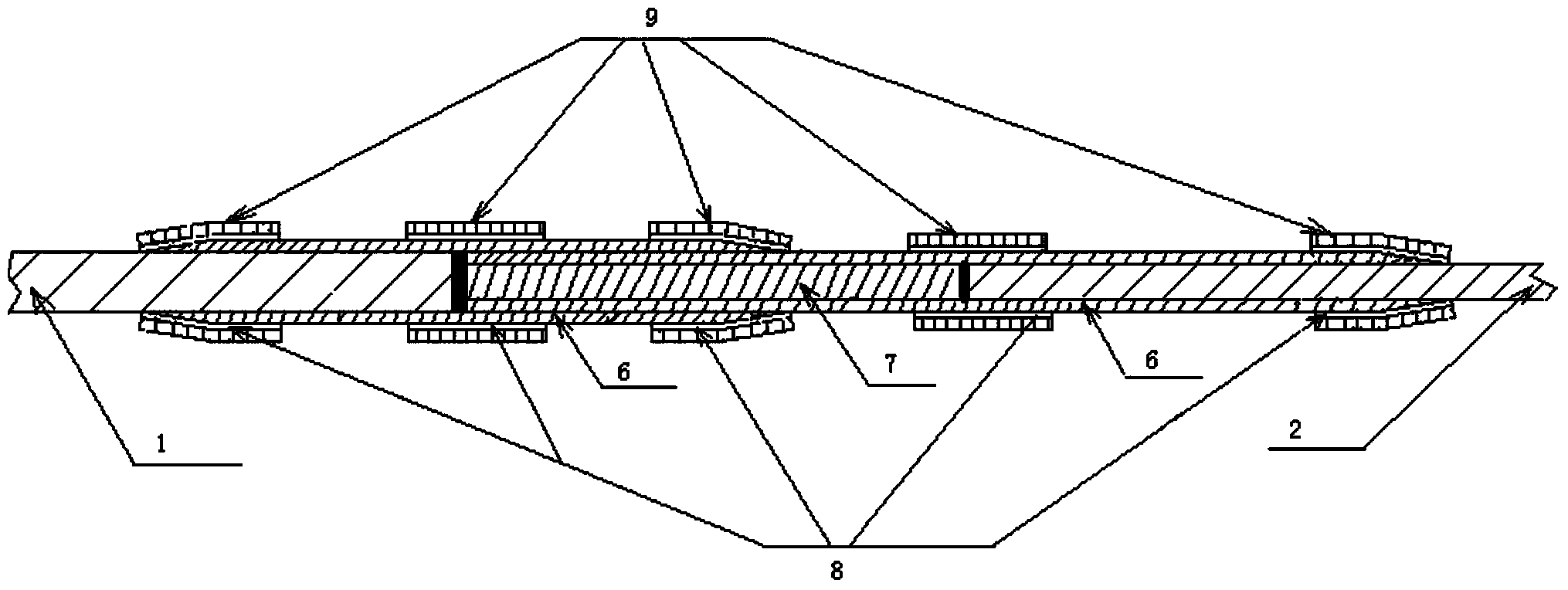

[0031] 2) if image 3 As shown, the diameter of the thin end / diameter of the thick end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com