Monitoring device and online monitoring method of quick closing process of steam turbine inlet valve

A process monitoring and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as the trend that cannot reflect the whole process of valve closing, the loss of monitoring of valve status, and the inability to perform testing, so as to achieve equipment predictability Maintenance, reduce operation safety risks, and achieve the effect of rapid fault location

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

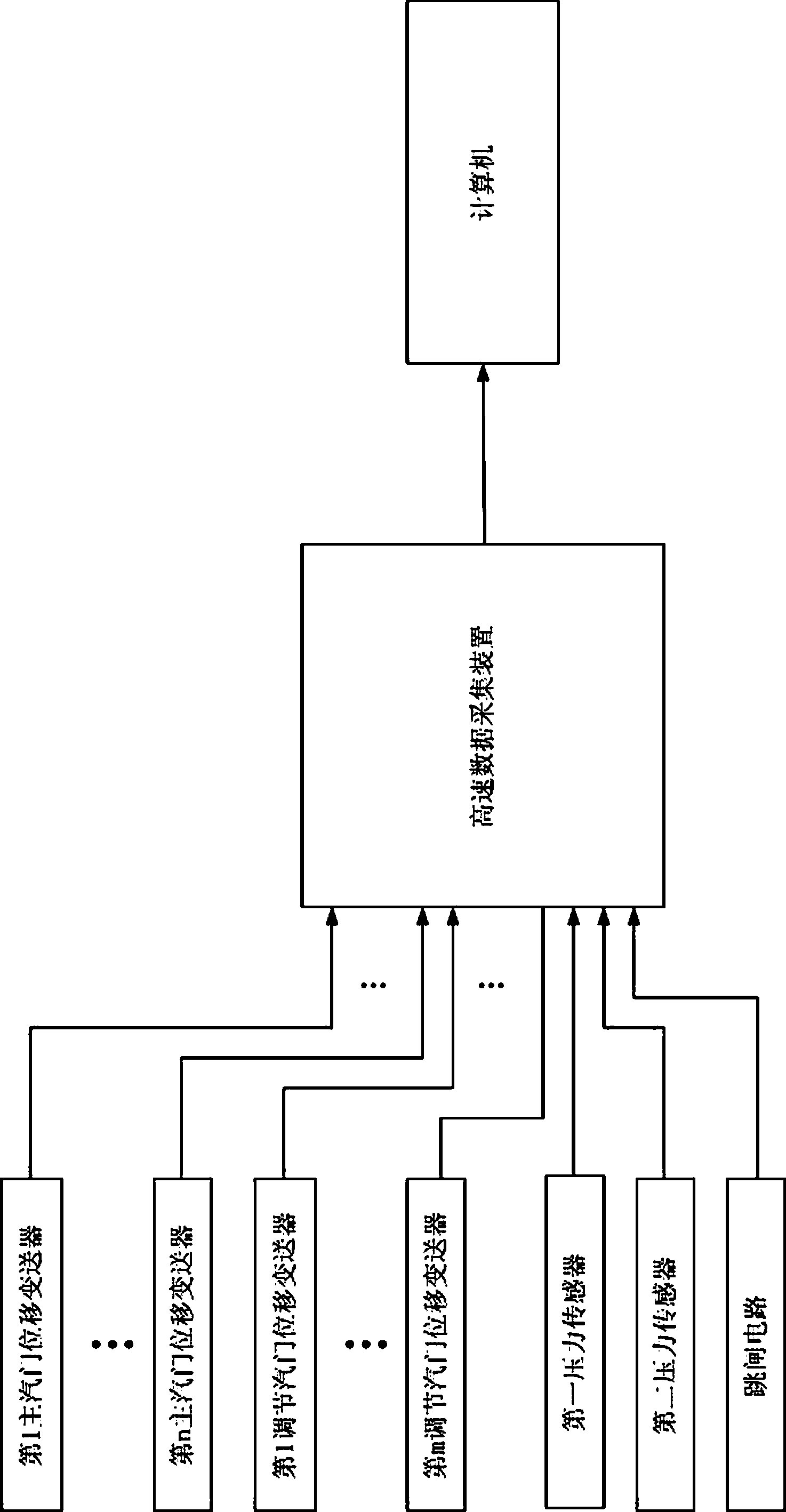

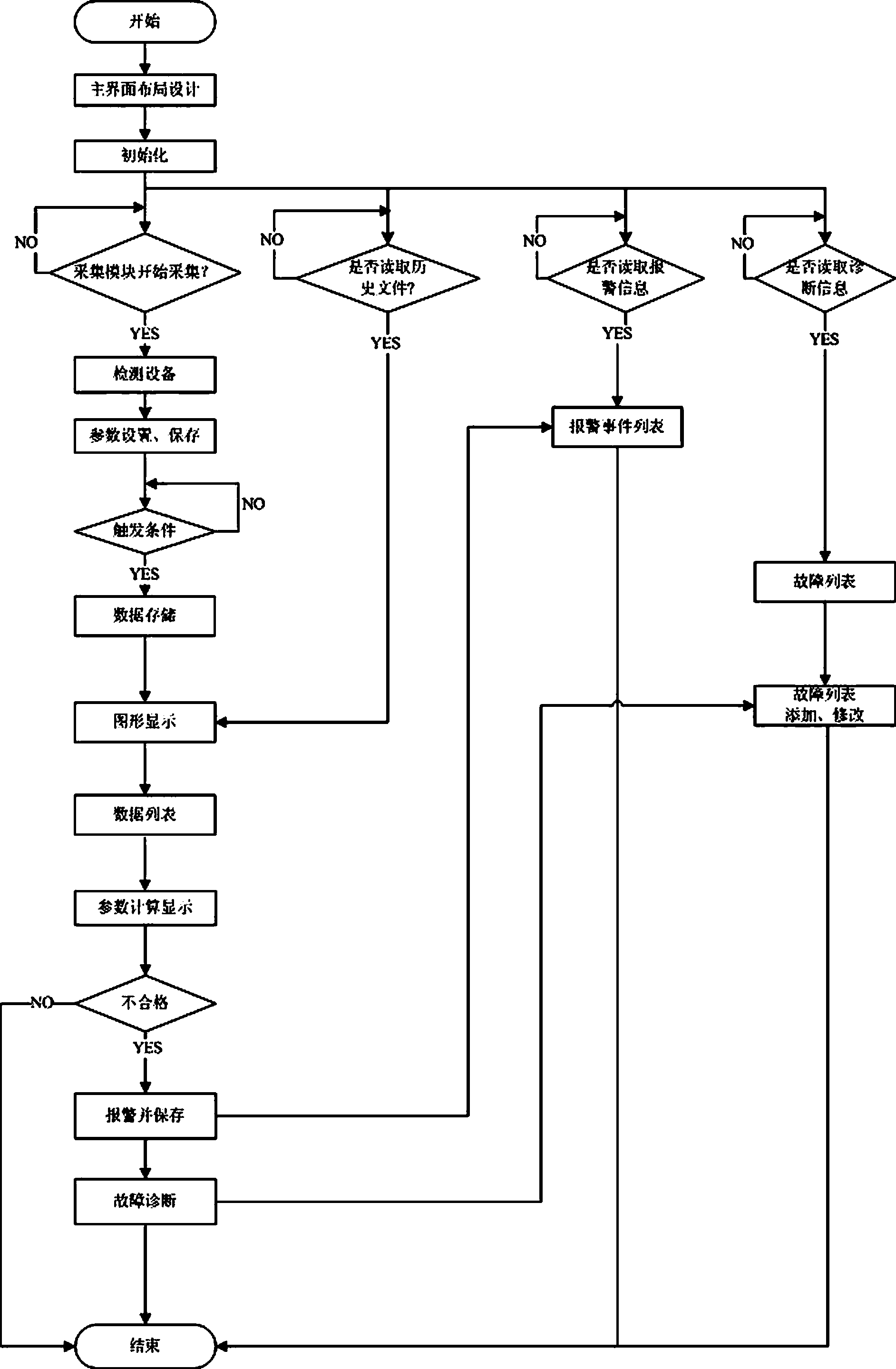

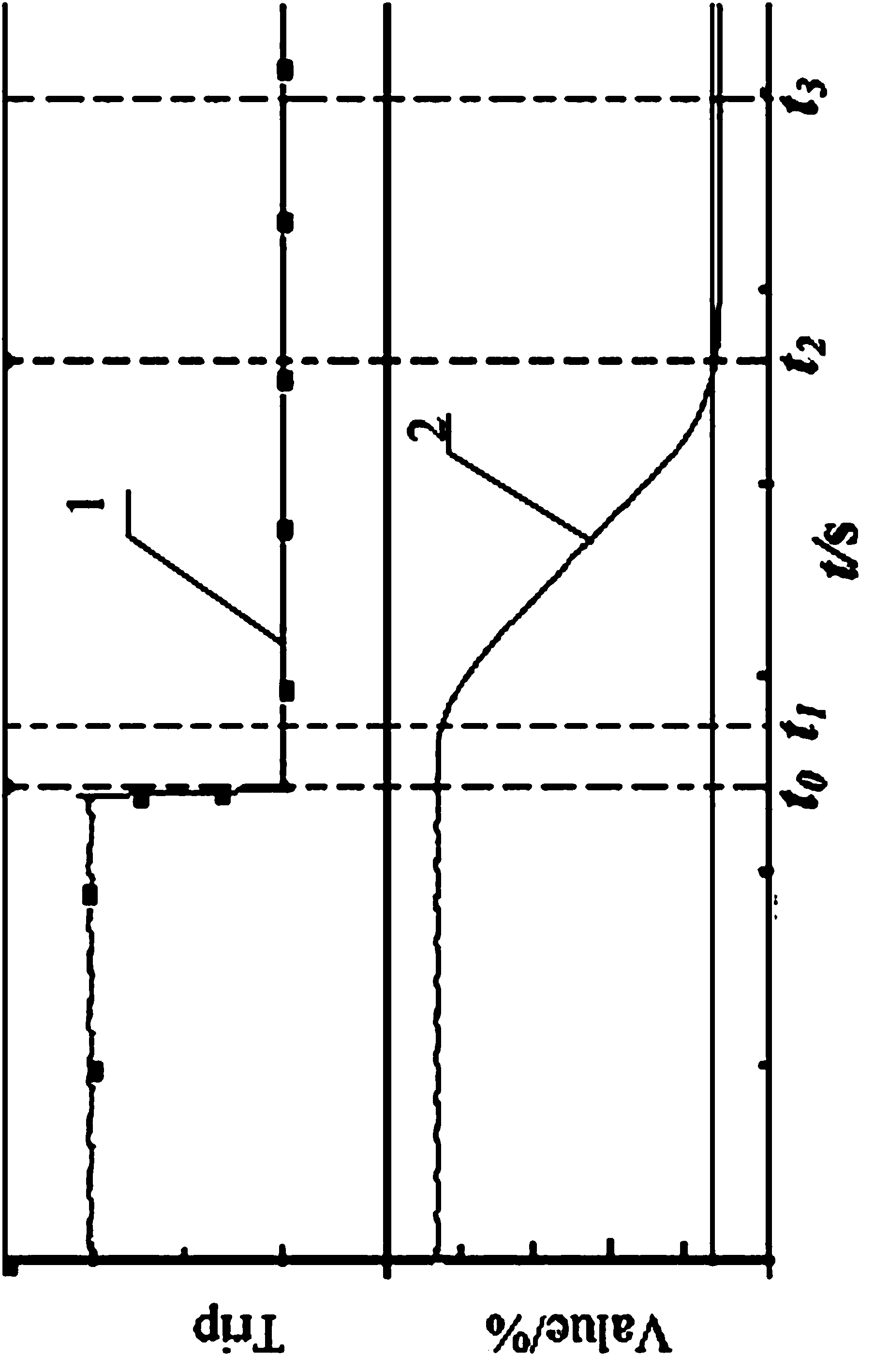

[0025] Depend on Figure 1-4 From the shown embodiment, it can be seen that the monitoring device for the fast closing process of the steam inlet valve of the steam turbine includes the first to nth main steam valve displacement transmitters for measuring the opening of the main steam valve of the steam turbine, and the first to nth main valve displacement transmitters for measuring the opening of the steam turbine regulating valve. m adjusts the valve displacement transmitter, the first pressure sensor for measuring the oil pressure of the oil motor, the second pressure sensor for measuring the AST oil pressure, the trip circuit for measuring the trip signal, the high-speed data acquisition device and the computer; the n is greater than or equal to 2 is an integer less than 12; the m is an integer greater than or equal to 2 and less than 12;

[0026] The first to nth main steam valve displacement transmitters are installed on the main steam valve lever of the steam turbine; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com