Parallel-type oil-gas separator for crankcase ventilation

A technology of oil-gas separator and crankcase ventilation, which is applied in the direction of crankcase ventilation, machine/engine, engine components, etc. It can solve the problems of complex structure, high cost, and engine space occupation, so as to achieve flexible space layout, improve emission performance, The effect of high-efficiency oil and gas separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

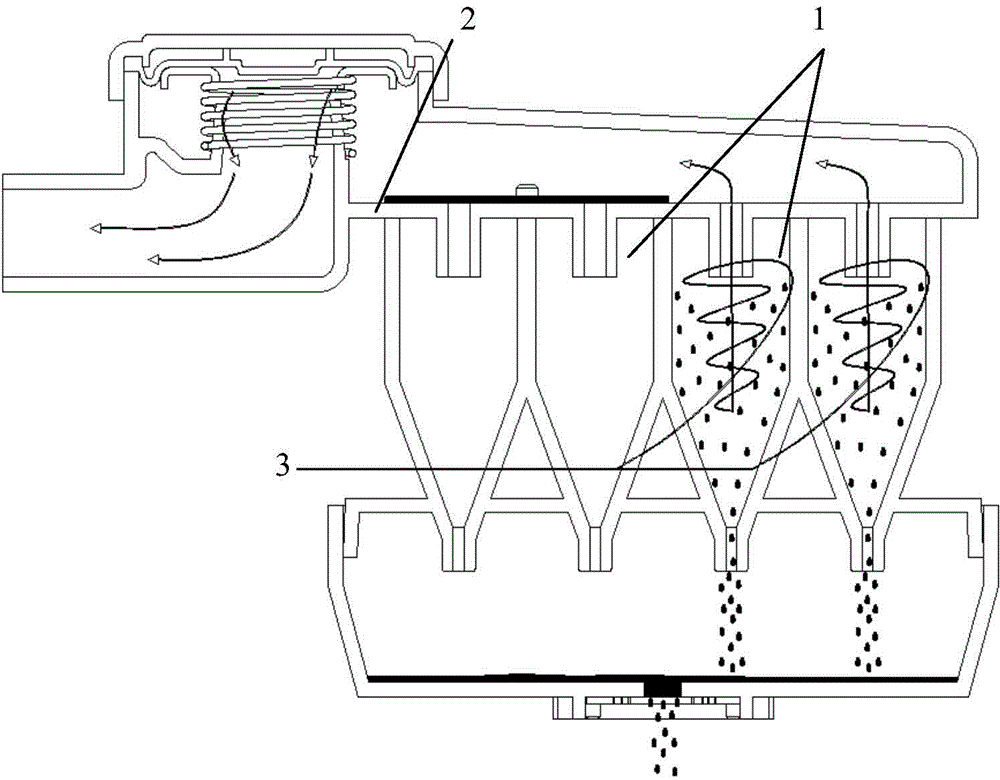

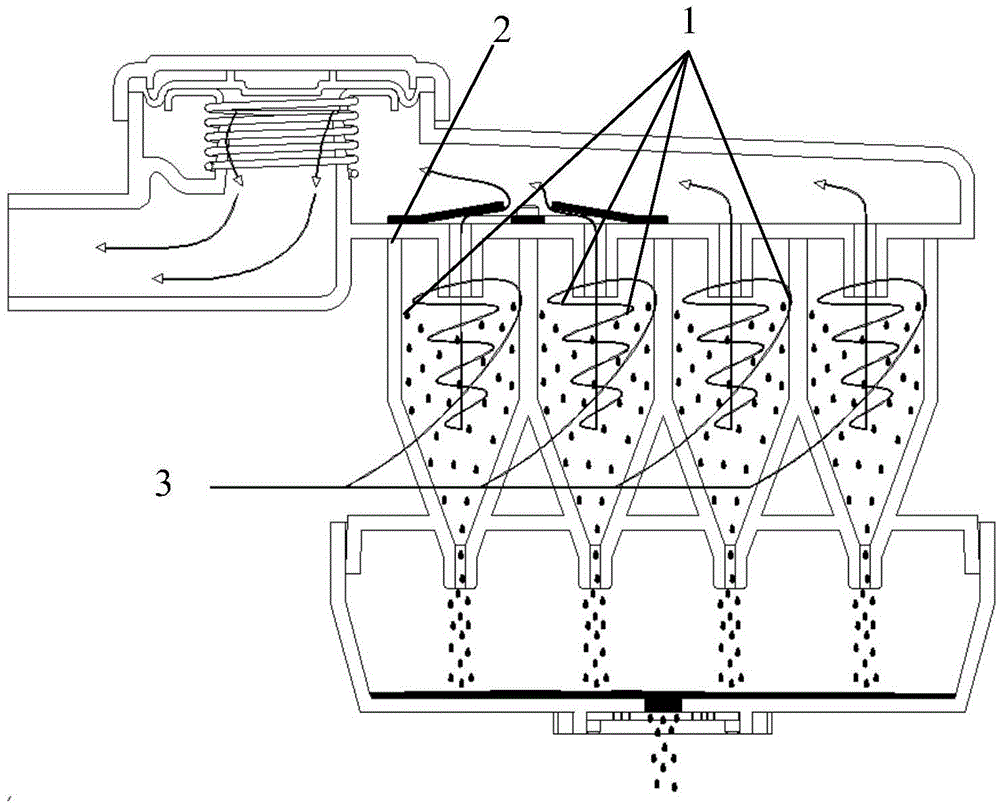

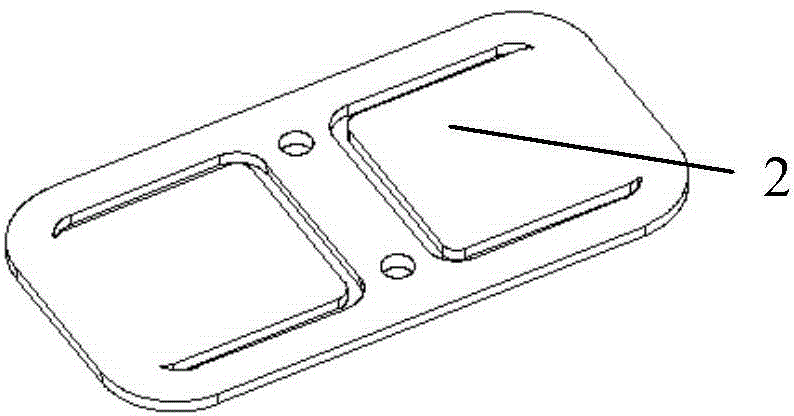

[0016] The side-by-side oil-gas separator for crankcase ventilation of the present invention is composed of a vibration valve and 4 side-by-side swirl chambers, a vibration valve is arranged above the 2 whirl chambers, and the vibration valve is arranged above the two whirl chambers , The vibrating valve is a sheet-like structure of spring steel material, with an opening on it, which can be opened or closed under the action of external force. The vibrating valve is assembled above the swirl chamber by riveting or clipping.

[0017] When the engine is working, the pressure in the crankcase is greater than the pressure in the intake manifold. With the different operating conditions of the engine, the amount of crankcase blow-by gas 3 changes, so the pressure difference between the crankcase and the intake manifold also changes accordingly. In the case of low blow-by gas in the crankcase, the pressure difference between the crankcase and the intake manifold is small, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com