Intelligent stepless-speed-regulation weighing feeder controller for driving DC 220V feed throwing motor

A technology of stepless speed regulation and throwing motor, which is applied in the field of controllers, can solve the problems of inability to accurately control and grasp the feeding amount, and achieve improved feed utilization, large output torque, and stable driving waveform. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

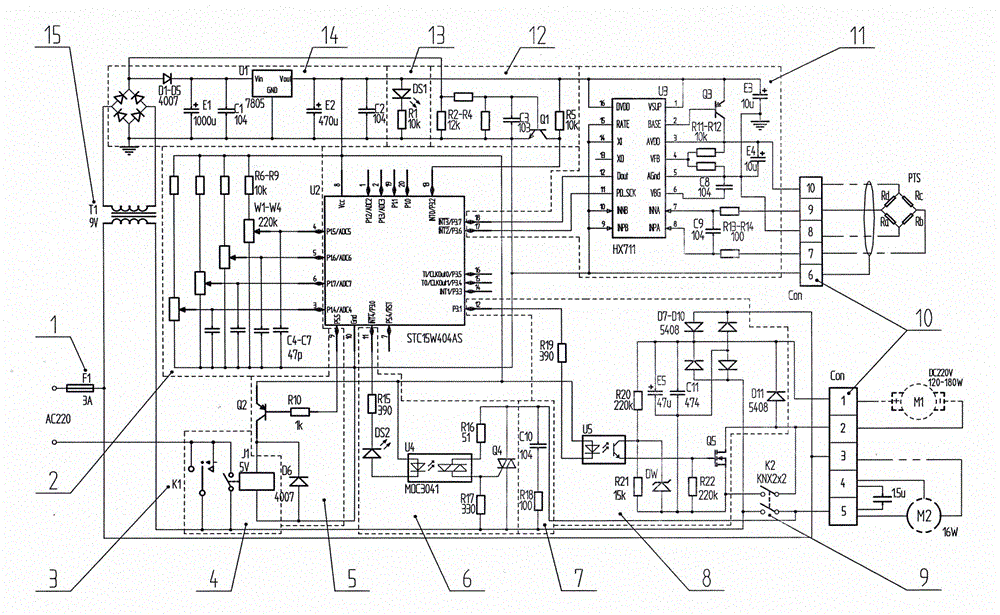

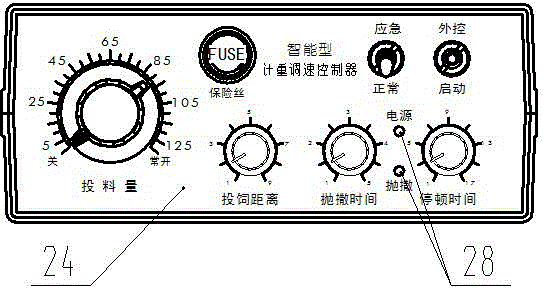

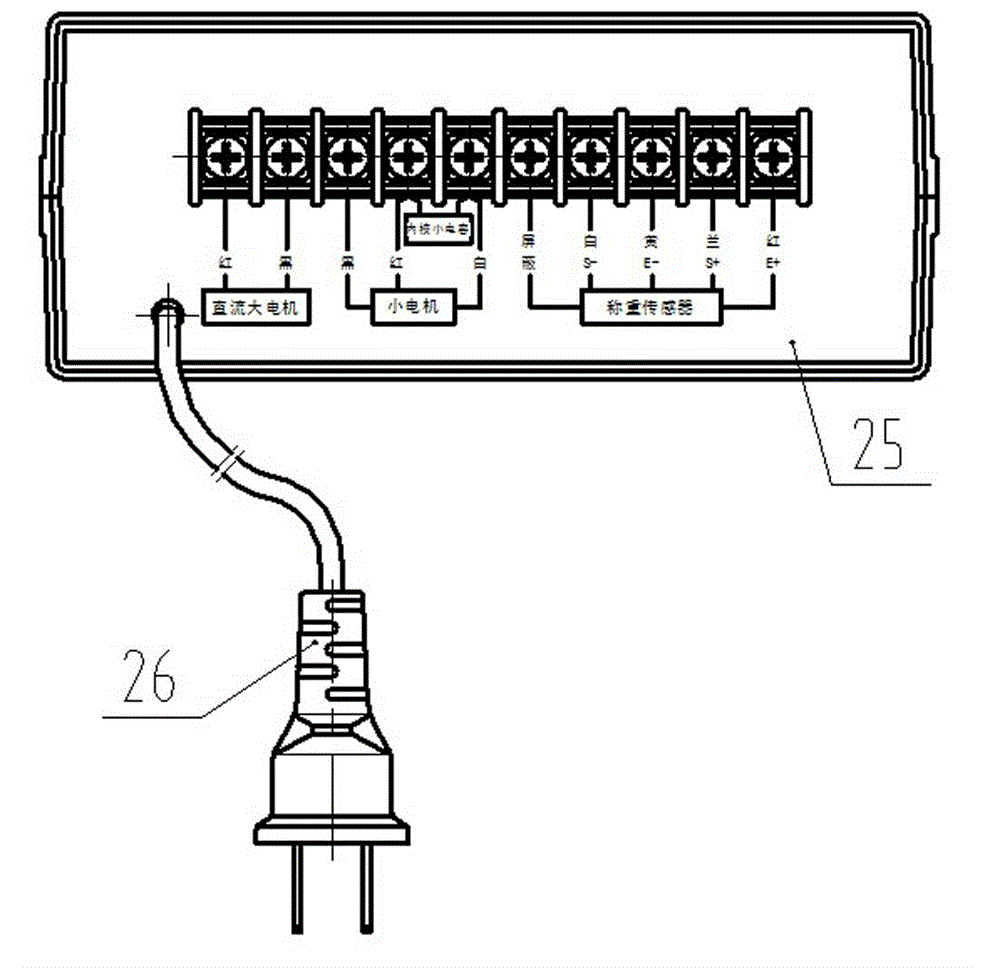

[0014] Such as Figure 1-4 As shown, the intelligent stepless speed regulation weighing controller includes an insurance circuit 1, an input setting circuit 2, a reset switch 3, a self-locking circuit 4, a relay J1 drive protection circuit 5, a throwing indicator drive output circuit 6, and an output protection circuit 7. Speed regulating drive output circuit 8, emergency switch 9, terminal block 10, weighing detection circuit 11, zero-crossing detection circuit 12, power indicator circuit 13, rectification and voltage stabilization circuit 14, transformer 15T1, single-chip microcomputer 18U2 and relay J1, among which : The safety circuit 1 is made up of the fuse holder 19 and the fuse inserted into the inner cavity of the fuse holder; the self-locking circuit 4 is made up of the normally open contact of the relay J1 and the reset contact of the reset switch 3; the input setting circuit 2 is made up of the AD of the single-chip microcomputer 18U2 Port pins 3, 4, 5, 6 and pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com