Passive ultrahigh-frequency electronic-label structure used for automobile

An electronic tag and ultra-high frequency technology, which is applied in the direction of record carriers used in machines, instruments, computer components, etc., can solve the problems of small gain, short recognition distance, narrow bandwidth, etc., and achieve stable antenna performance, high sensitivity, and high Good frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

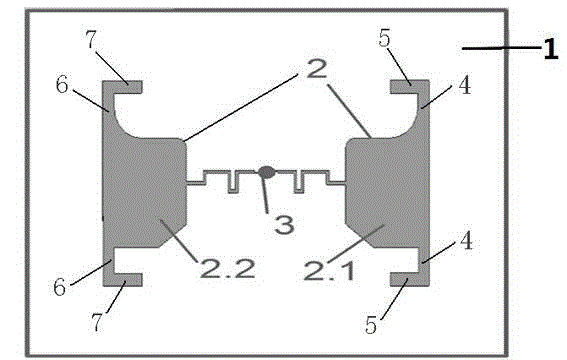

[0015] like figure 1 As shown, the present invention includes a substrate 1, a tag antenna structure 2, and an UHF radio frequency identification chip 3. The tag antenna structure 2 is printed on the substrate 1, and the UHF radio frequency identification chip 3 is welded to the tag antenna structure by welding technology. 2 feed ports.

[0016] The tag antenna structure 2 comprises a first substructure section 2.1 and a second substructure section 2.2. The first substructure section 2.1 is a "mountain" character structure rotated 90° counterclockwise, that is, the middle of the first substructure section 2.1 is a bump, and the two ends of the bump are respectively connected to the transition section 4, and the transition section 4 is connected to it. Vertical extension 5. One end of the bump has a rounded transition to the transition section 4 , and a right-angle tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com