Titanium-silicon-carbon composite wave-absorbing agent and preparation method and application thereof

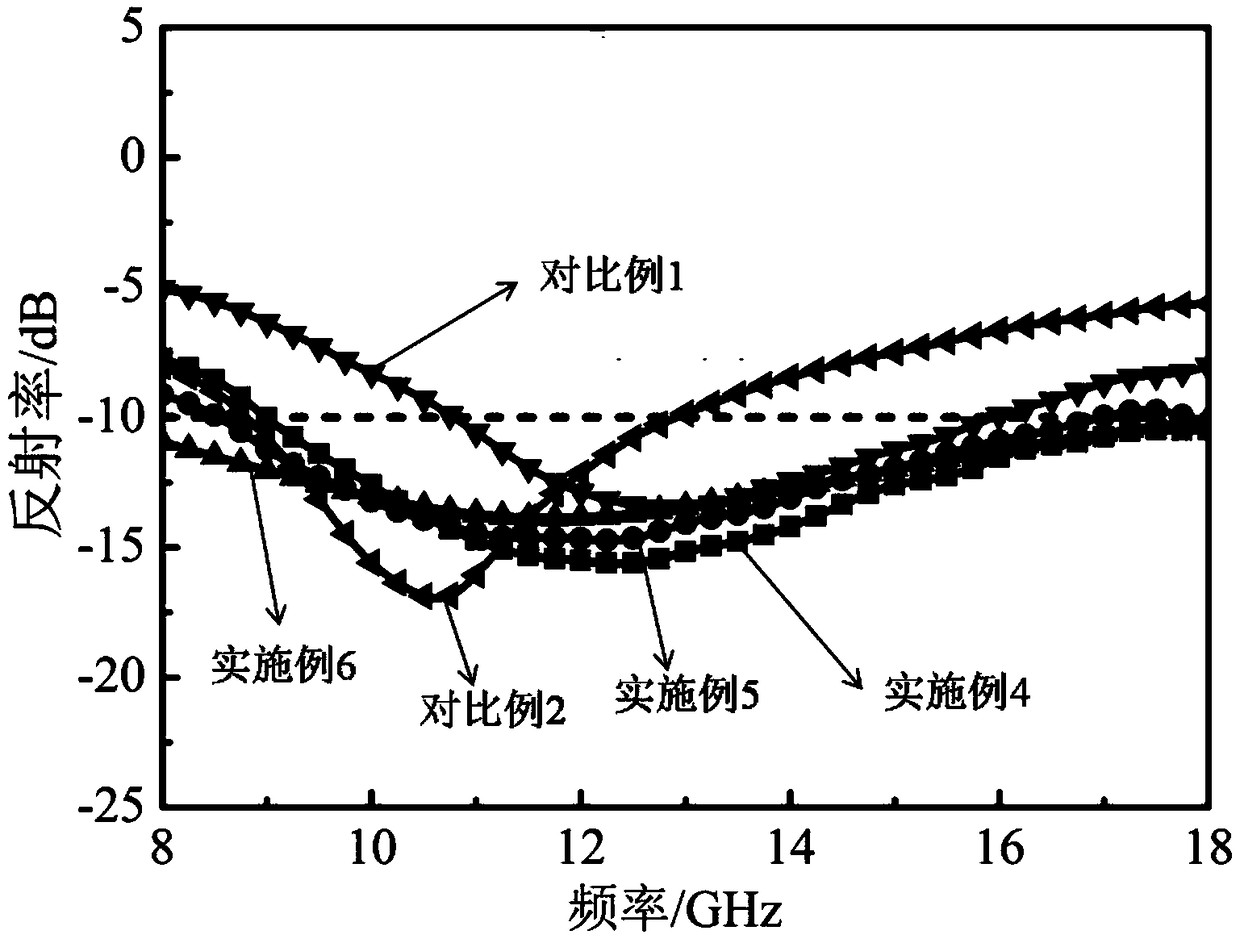

A technology of composite wave-absorbing materials and wave-absorbing agents, applied in chemical instruments and methods, other chemical processes, radiation-absorbing coatings, etc., can solve the problems of narrow electromagnetic wave absorption frequency band and poor electromagnetic impedance matching, and achieve low surface density, The effect of absorption frequency bandwidth, density and high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a Ti 3 SiC 2 The preparation method of composite wave absorbing agent comprises the following steps:

[0033] (1) Weigh 7.3g Ni(NO 3 ) 2 ·6H 2 O, 7.5g Zn(NO 3 ) 2 ·6H 2 O and 40.4gFe(NO 3 )·9H 2 O, and dissolved in a beaker with 500mL deionized water to prepare a mixed nitrate solution; then add 37.8g complexing agent citric acid, then slowly add a 40% ammonia solution, adjust the pH to 7, and stir evenly form a mixed solution;

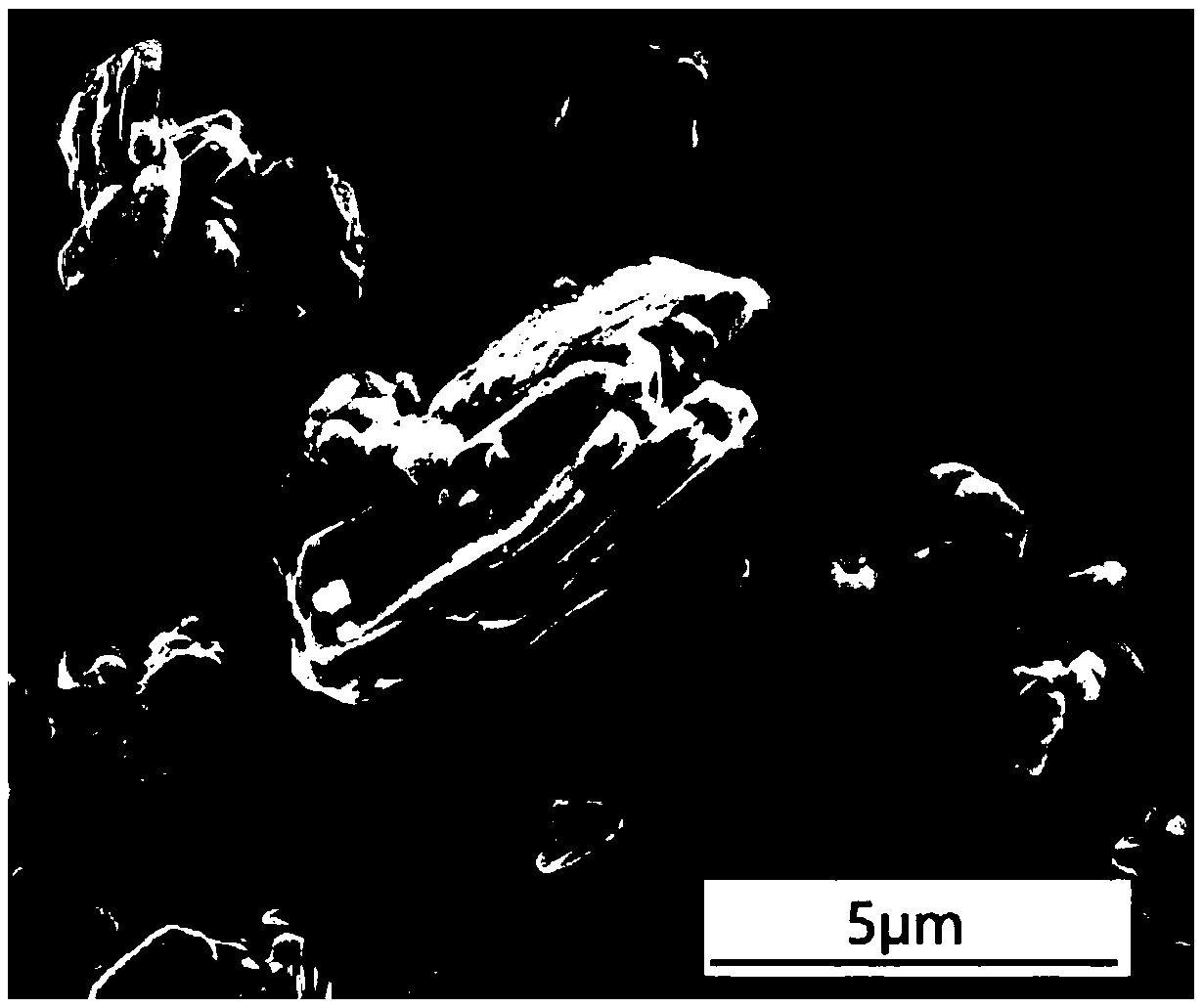

[0034] (2) 35.7g Ti 3 SiC 2 The powder is dispersed in the mixed solution, placed in an 80°C water bath and heated and stirred for 5 hours to obtain a stable and uniform composite precursor sol;

[0035] (3) Place the prepared composite precursor sol in a drying oven at 120°C to dry, and the gel formed after the water evaporates is coated on the Ti 3 SiC 2 After the powder is surfaced, it is pre-fired at 400°C for 3h, then ground, and placed in a box-type resistance furnace for sintering at 600°C for 2h to o...

Embodiment 2

[0038] The invention provides a Ti 3 SiC 2 The preparation method of composite wave absorbing agent comprises the following steps:

[0039] (1) Weigh 10.9g Ni(NO 3 ) 2 ·6H 2 O, 11.2g Zn(NO 3 ) 2 ·6H 2 O and 60.6gFe(NO 3 )·9H 2 O, and be dissolved in the beaker that 500mL deionized water is housed and make mixed nitrate solution; Then add 98.5g complexing agent ethylenediaminetetraacetic acid, then slowly add concentration and be 30% ammonia solution, adjust pH to 8 , uniformly stirred to form a mixed solution;

[0040] (2) 71.4g Ti 3 SiC 2 The powder is dispersed in the mixed solution, placed in a 90°C water bath and heated and stirred for 4 hours to obtain a stable and uniform composite precursor sol;

[0041] (3) Place the prepared composite precursor sol in a drying oven at 130°C to dry, and the gel formed after the water evaporates is coated on the Ti 3 SiC 2 After the powder is surfaced, it is pre-fired at 300°C for 4h, then ground, and placed in a box-type ...

Embodiment 3

[0043] The invention provides a Ti 3 SiC 2 The preparation method of composite wave absorbing agent comprises the following steps:

[0044] (1) Weigh 7.3g Ni(NO 3 ) 2 ·6H 2 O, 7.5g Zn(NO 3 ) 2 ·6H 2 O and 40.4gFe(NO 3 )·9H 2 O, and dissolved in a beaker with 500mL of deionized water to prepare a mixed nitrate solution; then add 15.9g of citric acid and 43.8g of ethylenediaminetetraacetic acid mixed complexing agent, and then slowly add a concentration of 40% ammonia Aqueous solution, adjust the pH to 7, and stir evenly to form a mixed solution;

[0045] (2) 59.5g Ti 3 SiC 2 The powder is dispersed in the mixed solution, heated and stirred in an 80°C water bath for 4 hours to obtain a stable and uniform composite precursor sol;

[0046] (3) Place the prepared composite precursor sol in a drying oven at 130°C to dry, and the gel formed after the water evaporates is coated on the Ti 3 SiC 2 After the powder is surfaced, it is pre-fired at 400°C for 3h, then ground, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com