Drying device for reconstituted tobacco production by means of dry method of paper-making

A drying device and technology for reconstituted tobacco leaves, which is applied in the field of drying devices for producing reconstituted tobacco leaves by dry papermaking, can solve the problems of overdrying, loss of tobacco substances, and lack of uniform air device, etc., to reduce the drying temperature and shorten the drying time. Drying time, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

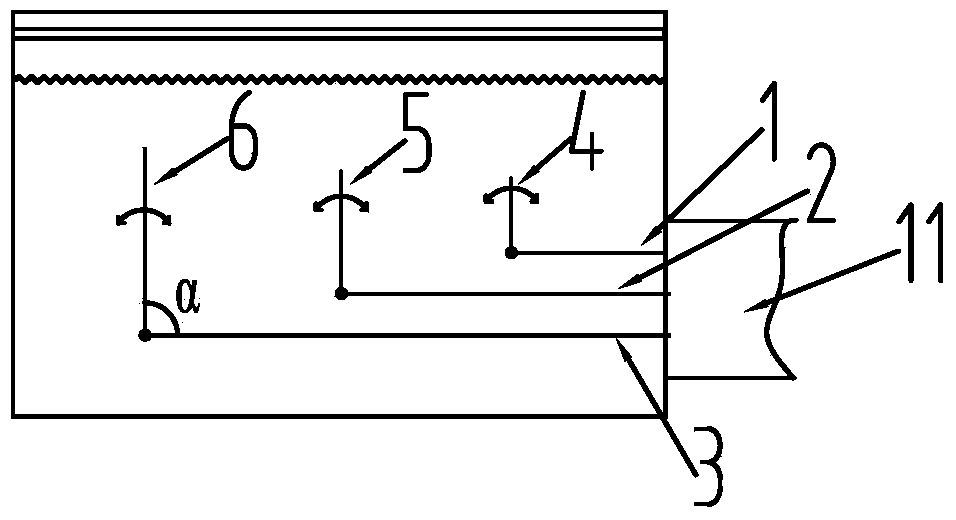

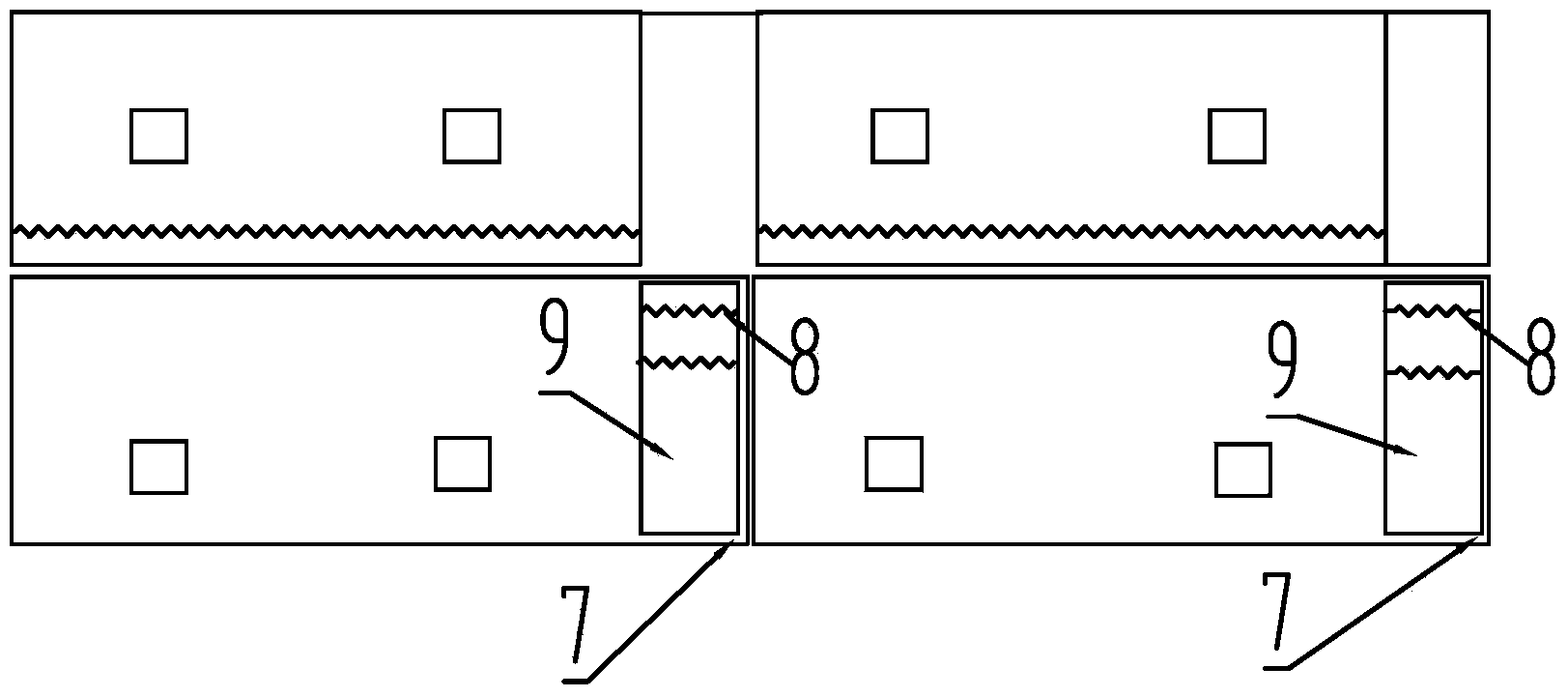

[0025] There are two sets of ovens in total, and each set of ovens is equipped with three uniform baffles, and the three uniform baffles are connected to the hot air inlet of the oven. The width of the oven is 1.28m, the height is 1.2m, the height of the hot air inlet is 40cm, and the distance between the three uniform air baffles is set to 10cm. The length of the first wind uniformity baffle 1 is 32cm, the length of the second wind uniformity baffle 2 is 64cm, and the length of the third wind uniformity baffle 3 is 96cm. The front ends of these three fixed wind evening baffles are respectively provided with three adjustable baffles connected by movable pins. The height of the first adjustable baffle 4 is 30cm, the height of the second adjustable baffle 5 is 40cm, and the third The height of the adjustable baffle plate 6 is 50cm. The adjustable baffle and the wind uniform baffle are flexibly connected, and the included angle can be adjusted between 60°-150°.

[0026] A commo...

Embodiment 2

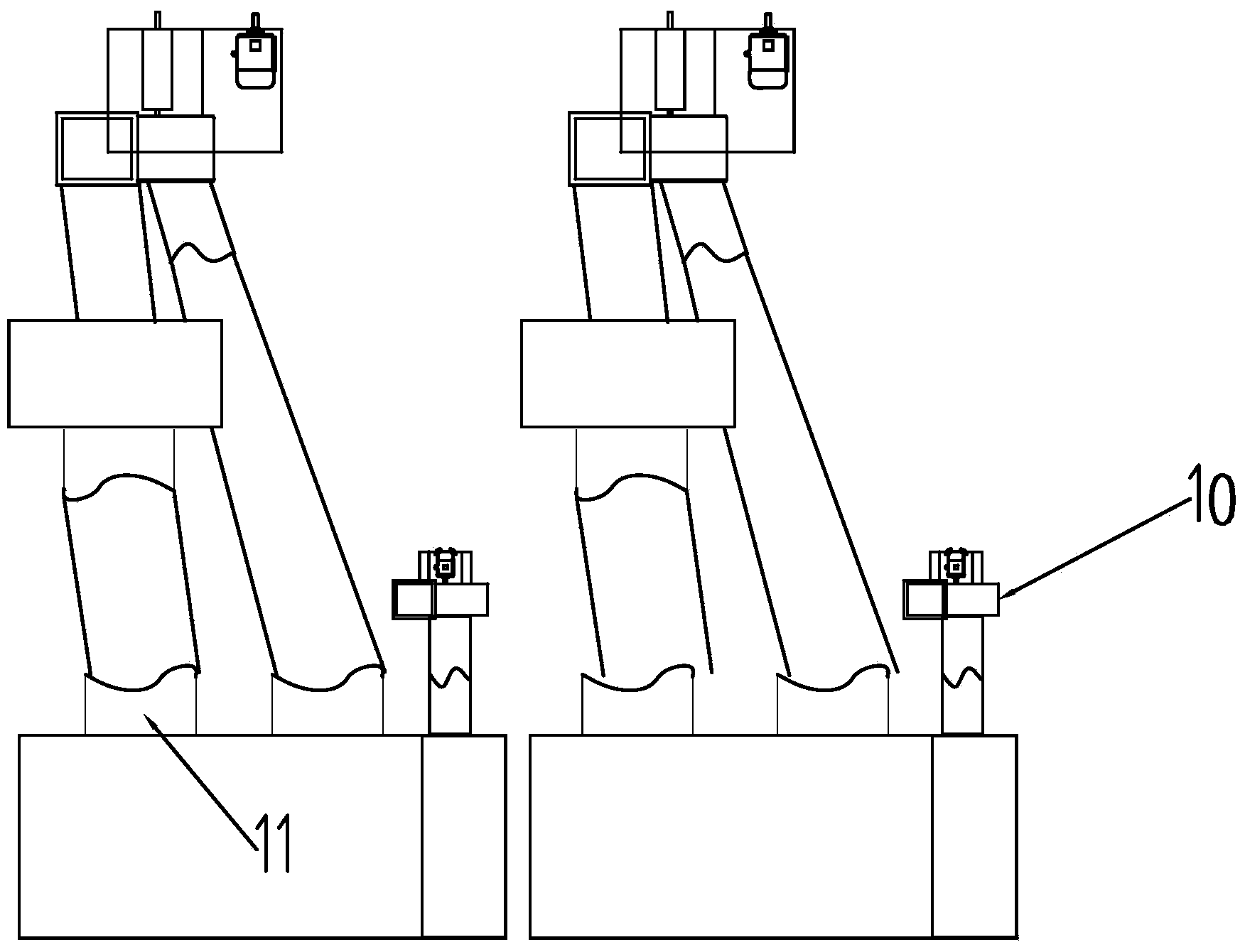

[0029] Set the temperature of the oven to 120°C, the air volume of the negative pressure fan to 60%, the angle of the guide plate 8 in the negative pressure box 9 to be 80 degrees, turn on the heating fan, and the hot air passes through the heat exchanger to the hot air inlet 11 of the oven, and the heat The air passes through the three fixed air uniformity baffles 1, 2, and 3 to evenly reach the four areas of the oven to keep the hot air vertically uniform and heat up the oven as a whole. According to the display data of the lateral temperature of the oven, the adjustable baffles 4, 5, and 6 connected to the fixed air-distributing baffles 1, 2, and 3 with movable pins are respectively adjusted until the horizontal hot air of the oven is uniform. The whole machine is turned on according to the program. After the fiber is formed in the forming part, the substrate is transferred to the spraying position through the transfer net for spraying and then enters the oven. The negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com