Gas flow equalizing device of spraying tower

A spray tower, gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of lack of uniform flow, easy ash accumulation, water accumulation, etc., to avoid ash accumulation and improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

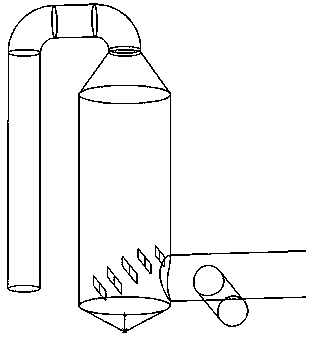

[0023] Embodiment 1: as figure 1 As shown, the flow equalizing device is composed of five straight plates with a width of about one meter. The straight plates are arranged in a ladder shape with unequal intervals at the lower part of the spray tower. When the inlet gas passes through the first straight plate, part of the gas is blocked by the straight plate. Change direction, flow upwards, forming the first diversion, after the diversion effect of 5 straight plates, the flow distribution of the gas in the Z direction is basically uniform, as shown in Figure 4 shown. At the same time, in the x direction, due to the blocking effect of the straight plate, the gas flows to both sides after contacting the straight plate, realizing the flow distribution of the gas in the x direction, as shown in Figure 5 As shown, so as to realize the flow distribution of gas in the entire spray tower, the flow equalization effect diagram is shown in Figure 7 shown.

Embodiment 2

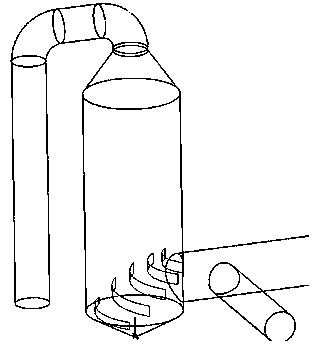

[0024] Embodiment 2: as figure 2 As shown, the flow equalizing device is composed of five arc-shaped plates with a width of about one meter. The arc-shaped plates are arranged in a ladder shape with unequal intervals at the lower part of the spray tower. Near the gas inlet side, due to the inherent characteristics of the flow field, the unevenness of the flow field is relatively large, and the use of curved plates can better solve the problem of uneven distribution of the flow field. The schematic diagram of the arc-shaped plate current equalization device is as follows: figure 2 As shown, the current equalization effect diagram is shown in Figure 8 shown.

Embodiment 3

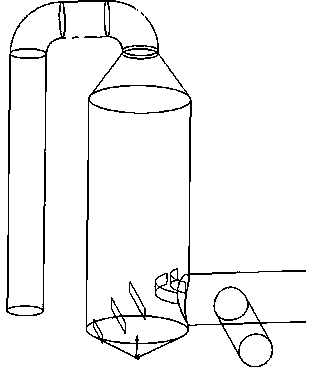

[0025] Embodiment 3: as image 3 As shown, the flow equalizer consists of 2 curved plates with a width of about one meter and three straight plates with a width of about one meter. The arc-shaped plates and straight plates are arranged in a ladder shape with unequal intervals at the lower part of the spray tower. For construction and maintenance issues, set the two flow distribution plates near the gas inlet side as curved plates, and the other three plates as straight plates. Its current equalization effect diagram is as follows Figure 9 shown.

[0026] In summary, the three current equalization devices mentioned in the present invention are all composed of five steel plates with a width of about one meter (the steel plates can be straight plates, curved plates, curved plates+straight plates), the thickness of the steel plates is about 16mm, and the steel plates are in the The lower part of the spray tower is arranged in a ladder shape with unequal intervals. When the inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com