Automatic blending and controlling system of oil well binary composite modifying and flooding agent

A binary compound and control system technology, applied in mixers, mixing methods, mixer accessories, etc., can solve problems such as damage to the mixer blades and transmission gears, uniform dispersion and mixing of unfavorable materials, and large changes in material viscosity. The high degree of automation, the realization of intelligent operation and management, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

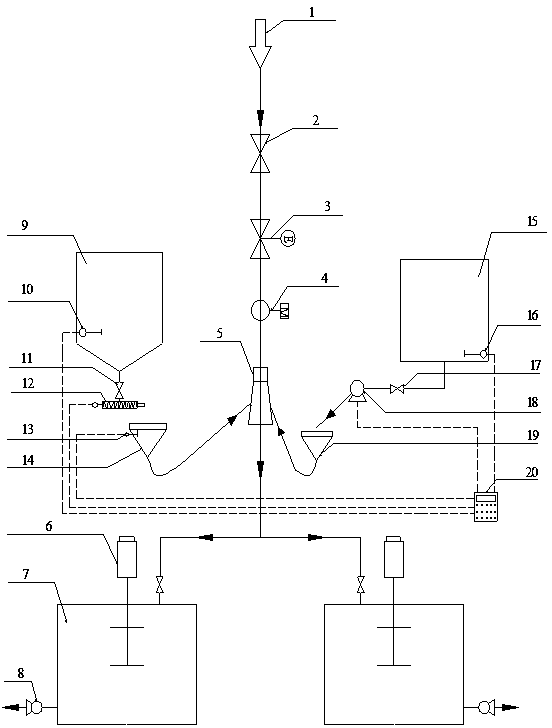

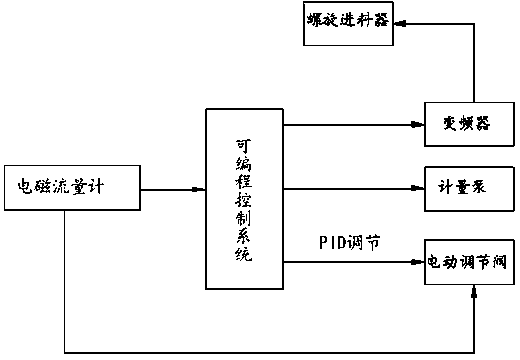

[0021] Add sufficient amount of reagent to the polymer storage tank and crosslinker storage tank. After opening the manual shut-off valve 1 of the high-pressure water injection pipeline, start the automatic control program. At this time, the electric control valve 2 is opened, and the high-pressure water is injected into the storage tank of the control and drive agent at a certain flow rate. When the accumulated liquid intake reaches a certain value, the metering pump 18 connected to the outlet of the cross-linking agent storage tank 15 is automatically turned on, and the cross-linking agent enters the hopper 19, and the negative pressure generated at the ejector 5 sucks the cross-linking agent along the pipeline into the storage tank of the displacing agent. When the cross-linking agent dosage reaches the preset value, the metering pump is automatically closed, and the injection of the cross-linking agent is stopped. When the accumulative liquid intake reaches another set v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com