Hydrofining catalyst for Fischer-Tropsch oil and preparation method thereof

A hydrofining and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as uneconomical, high value-added hydrogen consumption, and reduced yield of target products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

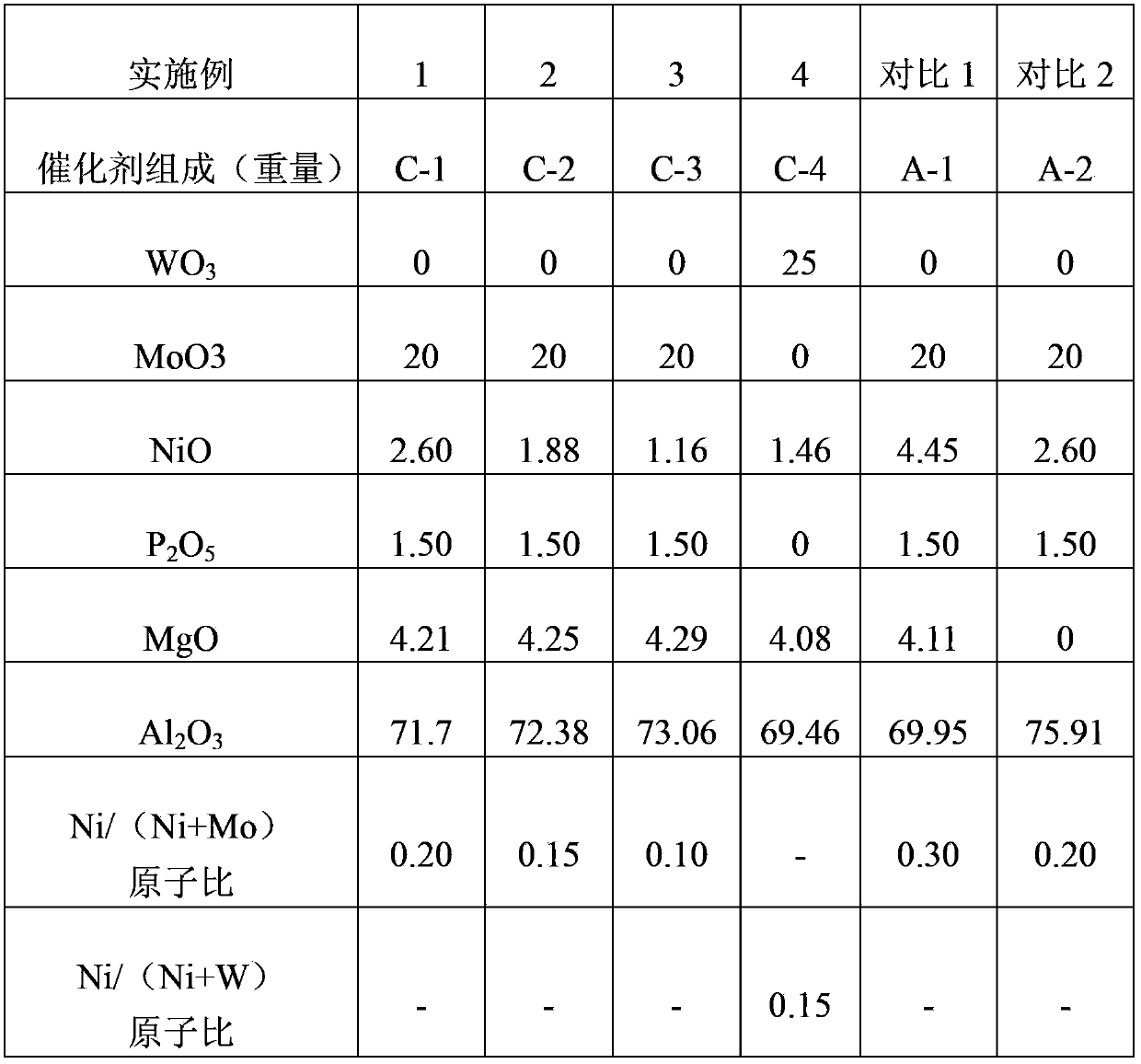

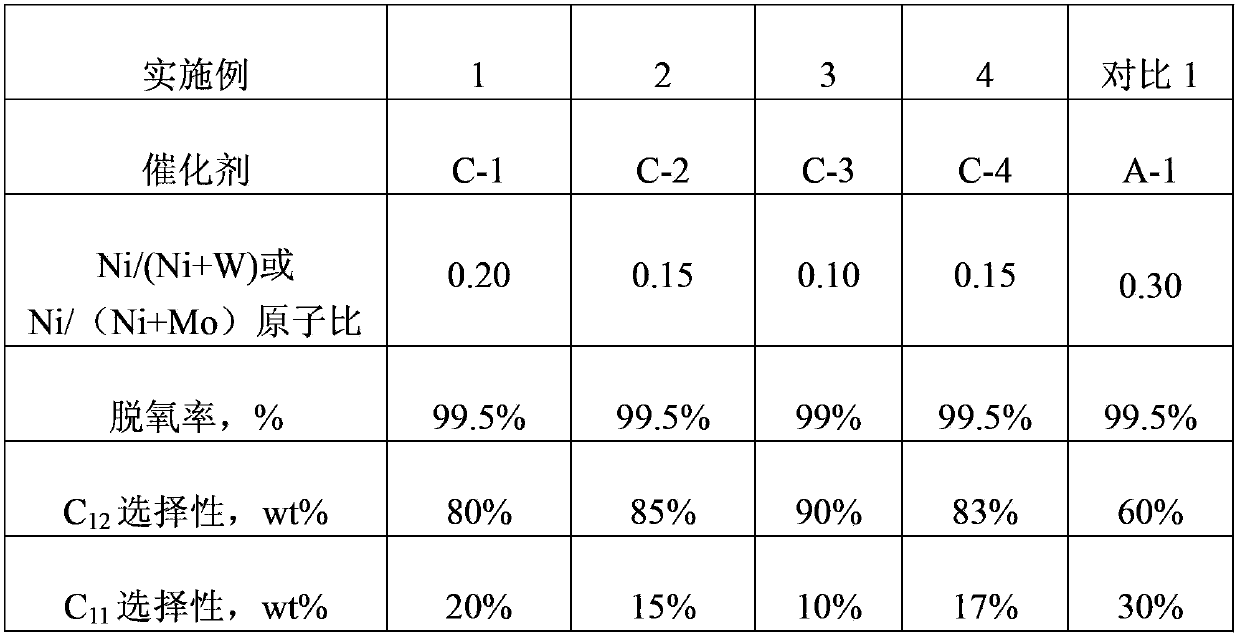

Embodiment 1

[0107] (1) Weigh 16 grams of magnesium nitrate (Mg(NO 3 ) 2 ˙6H 2 O) Add an appropriate amount of deionized water to prepare a magnesium-containing aqueous solution, and soak into 100 g of Al prepared by the method A above 2 O 3 On the porous carrier Z, the immersion time is 2 hours, after immersion, it is dried overnight, and dried at 120°C for 4 hours, and then calcined at 500°C for 4 hours to obtain Al containing MgO 2 O 3 Porous support Z-1.

[0108] (2) Weigh 2.43 grams of phosphoric acid with a purity of 85% and add it to an appropriate amount of deionized water, and then add 20 grams of molybdenum trioxide and 4.36 grams of basic nickel carbonate (NiCO 3 ˙2Ni(OH) 2 ˙4H 2 O), heat to a slight boiling, and continue heating until the precipitate is completely dissolved, soak it to 75.91 g of the above Al 2 O 3 On the porous carrier Z-1, immerse at room temperature for 2 hours, dry, and calcinate at 500°C for 4 hours to obtain Al 2 O 3 Porous carrier supports MgO, MoO 3 , P 2 O 5...

Embodiment 2

[0110] (1) Repeat the process of step (1) in Example 1;

[0111] (2) Weigh 2.43 grams of phosphoric acid with a purity of 85% and add it to an appropriate amount of deionized water, and then add 20 grams of molybdenum trioxide and 3.15 grams of basic nickel carbonate (NiCO 3 ˙2Ni(OH) 2 ˙4H 2 O), heat to a slight boiling, and continue to heat until the precipitate is completely dissolved, soak it to 76.63 grams of the above Al 2 O 3 On the porous carrier Z-1, immerse at room temperature for 2 hours, dry, and calcinate at 500°C for 4 hours to obtain Al 2 O 3 Porous carrier supports MgO, MoO 3 , P 2 O 5 And NiO catalyst C-2;

Embodiment 3

[0113] (1) Repeat the process of step (1) in Example 1;

[0114] (2) Weigh 2.43 grams of phosphoric acid with a purity of 85% and add it to an appropriate amount of deionized water, and then add 20 grams of molybdenum trioxide and 1.94 grams of basic nickel carbonate (NiCO 3 ˙2Ni(OH) 2 ˙4H 2 O), heat to a slight boiling, and continue heating until the precipitate is completely dissolved, soak it to 77.35 grams of the above Al 2 O 3 On the porous carrier Z-1, immerse at room temperature for 2 hours, dry, and calcinate at 500°C for 4 hours to obtain Al 2 O 3 Porous carrier supports MgO, MoO 3 , P 2 O 5 And NiO catalyst C-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com