Novel vibrating screen

A vibrating screen, a new type of technology, applied in the field of sieves, can solve the problems of easy clogging of the screen, inability to screen, affecting the screening efficiency, etc., and achieve the effect of avoiding adhesion, simple structure and good vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

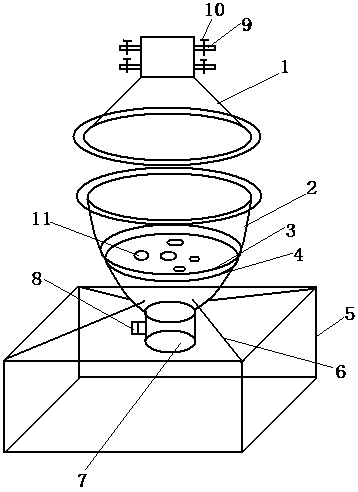

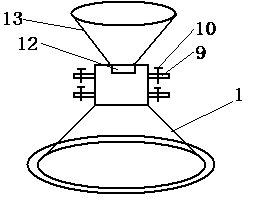

[0012] A new type of vibrating screen, including a frame 5, a shell, and a vibrating pump 8. The shell includes an upper shell 1 and a lower shell 2. The interior of the upper shell 1 and the lower shell 2 is a cavity, and the lower shell 2 A screen is installed inside, the lower shell 2 is connected to the frame 5 through a hard spring 6, the side wall of the lower shell 2 is provided with a vibrating pump 8, and the upper shell 1 is provided with a plurality of air holes 9, and the air holes 9 are provided with valves 10. The lower housing 2 is provided with a screen installation groove at the length of the lower housing 1 / 3-2 / 3 from the upper opening, the screen is installed in the installation groove, and the screen is detachably installed on the lower housing 2.

[0013] The screen consists of two layers, namely an upper screen 3 and a lower screen 4, and movable plastic washers 11 are scattered between the upper screen 3 and the lower screen 4 as supports, and the washers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com